Stirring device for plastic foam particle film coating dryer

A technology of stirring device and plastic foam is applied in the field of stirring device for plastic foam particle coated film dryer, which can solve the problems of small contact area between a stirring plate and the inner wall of a casing, increased maintenance cost, low production efficiency, etc. The effect of chemical production, improving production efficiency and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

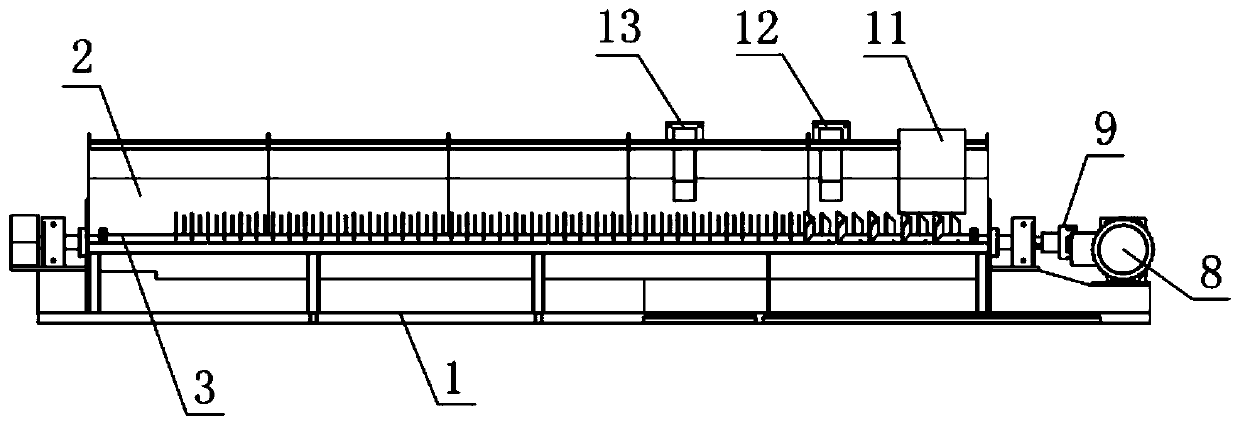

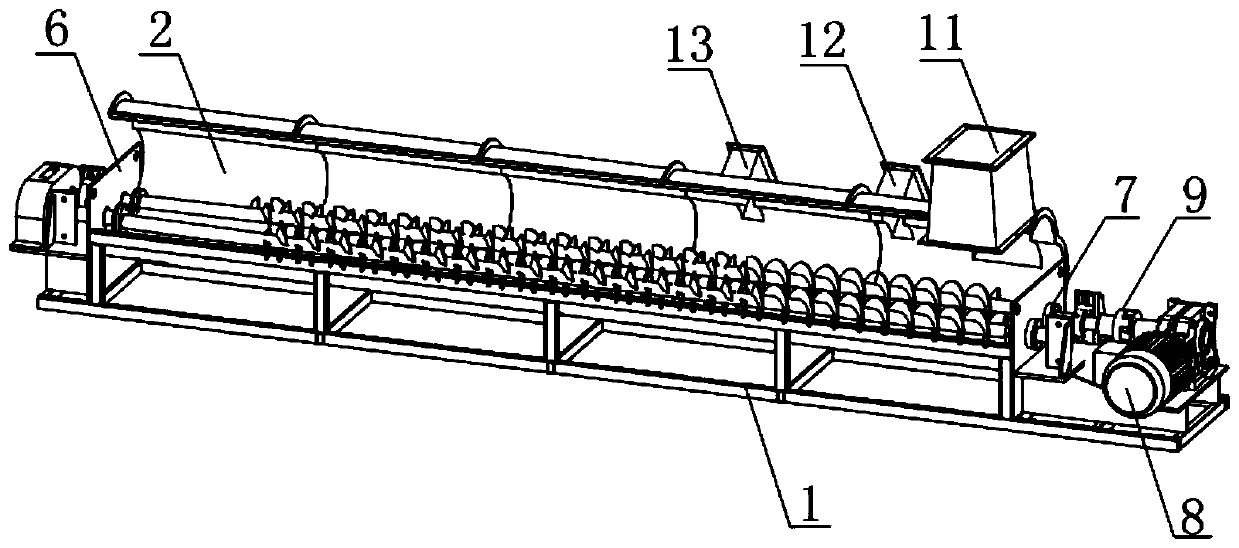

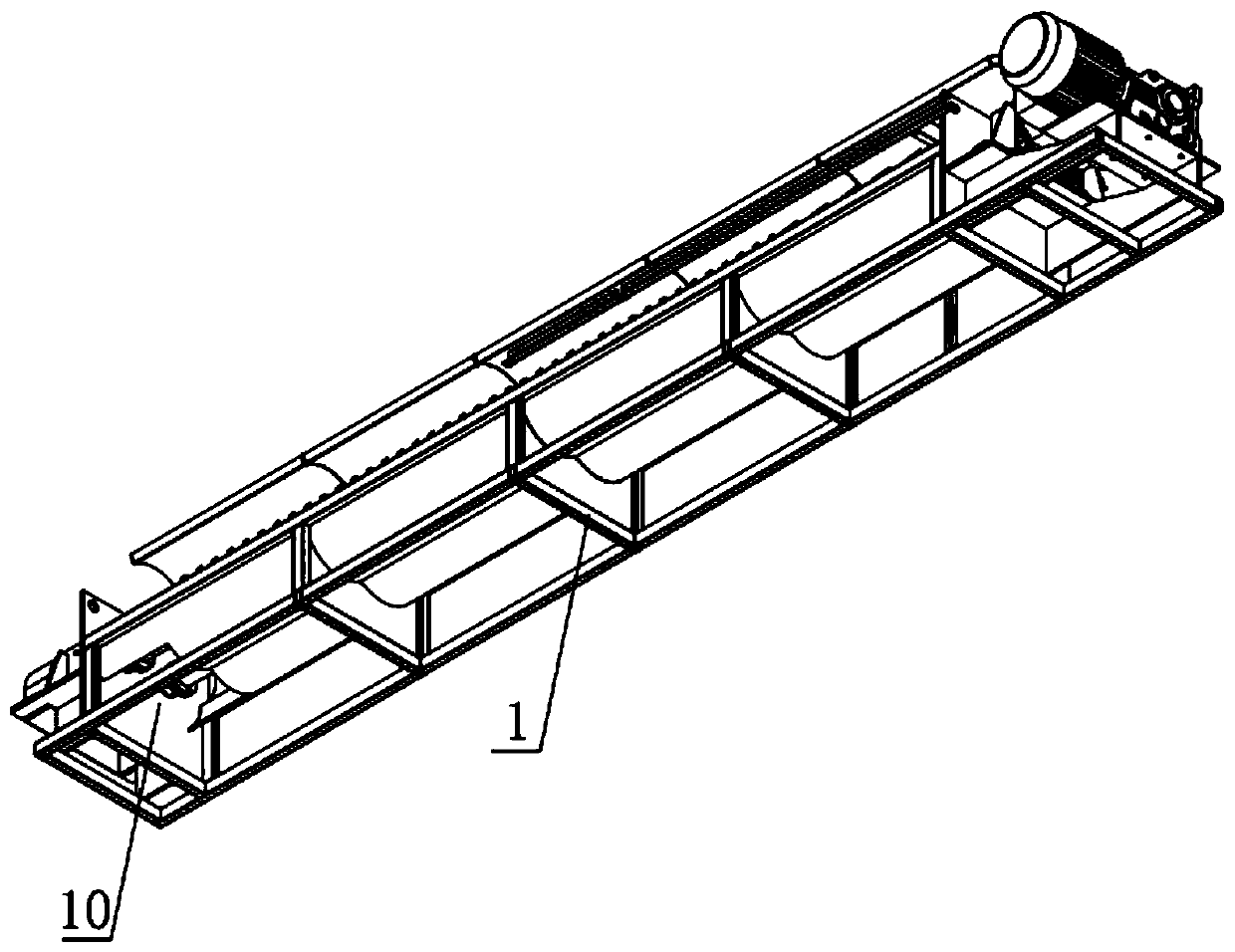

[0023] Such as Figure 1-5 As shown, the mixing device for the plastic foam particle coating dryer includes a frame 1 and a coating cavity 2 on the frame 1, and also includes a coating cavity 2 for mixing the particles with the coating solution. A stirring and rotating mechanism that performs uniform stirring and pushes particles to the discharging direction. The stirring and rotating mechanism includes a rotating shaft 3, on which a helical piece is spirally arranged along its axial direction, and the helical piece includes a continuous spiral for pushing particles to the discharging direction Sheet 4 and the intermittent spiral sheet for evenly stirring the pushed particles. The intermittent spiral sheet also has the function of assisting material pushing. The spiral sheet is divided into two parts: continuous spiral sheet and inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com