Hopper assembly for engineering vehicle

An engineering vehicle and assembly technology, applied in the direction of motor vehicles, vehicle parts, loading and unloading vehicle arrangements, etc., can solve the problems of affecting efficiency, poor adaptability of hoppers, increasing difficulty, etc., to achieve convenient installation and use, reduce effective vehicle width, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

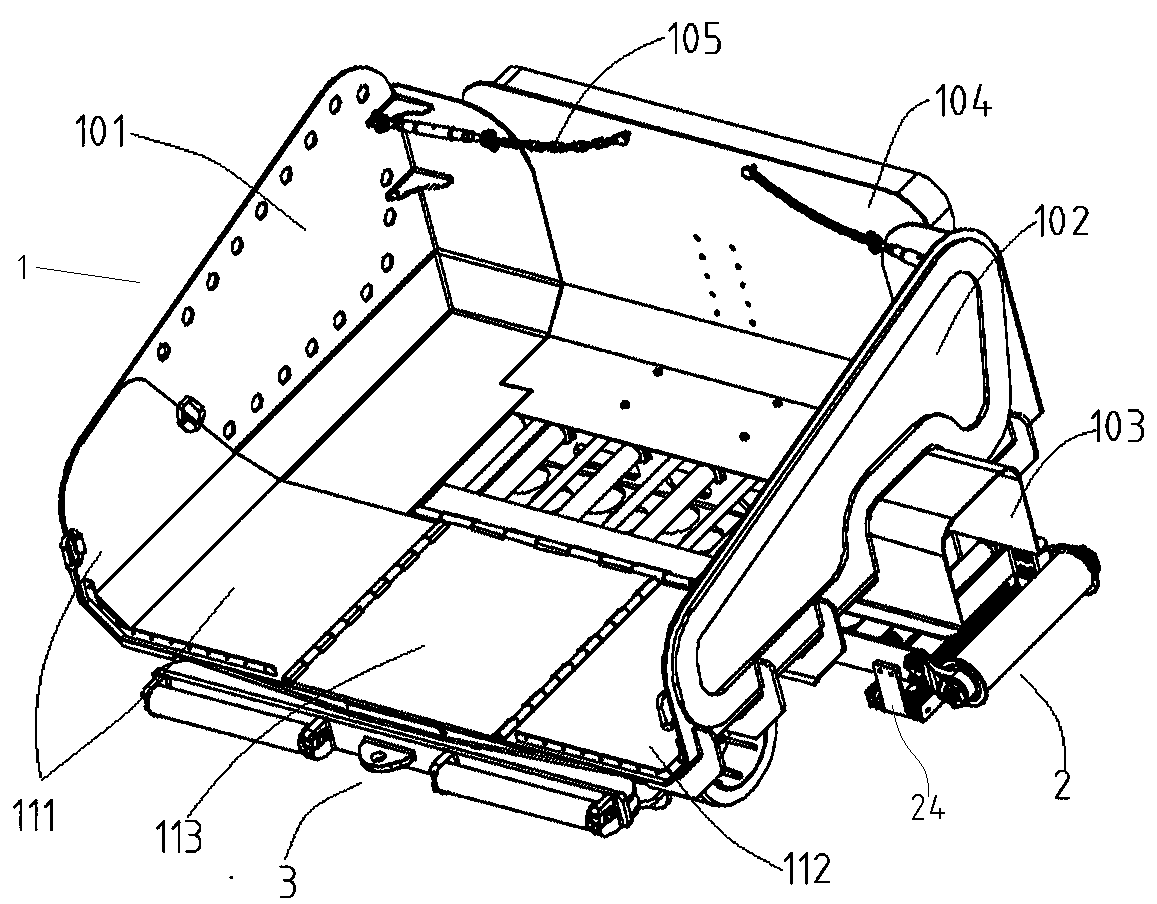

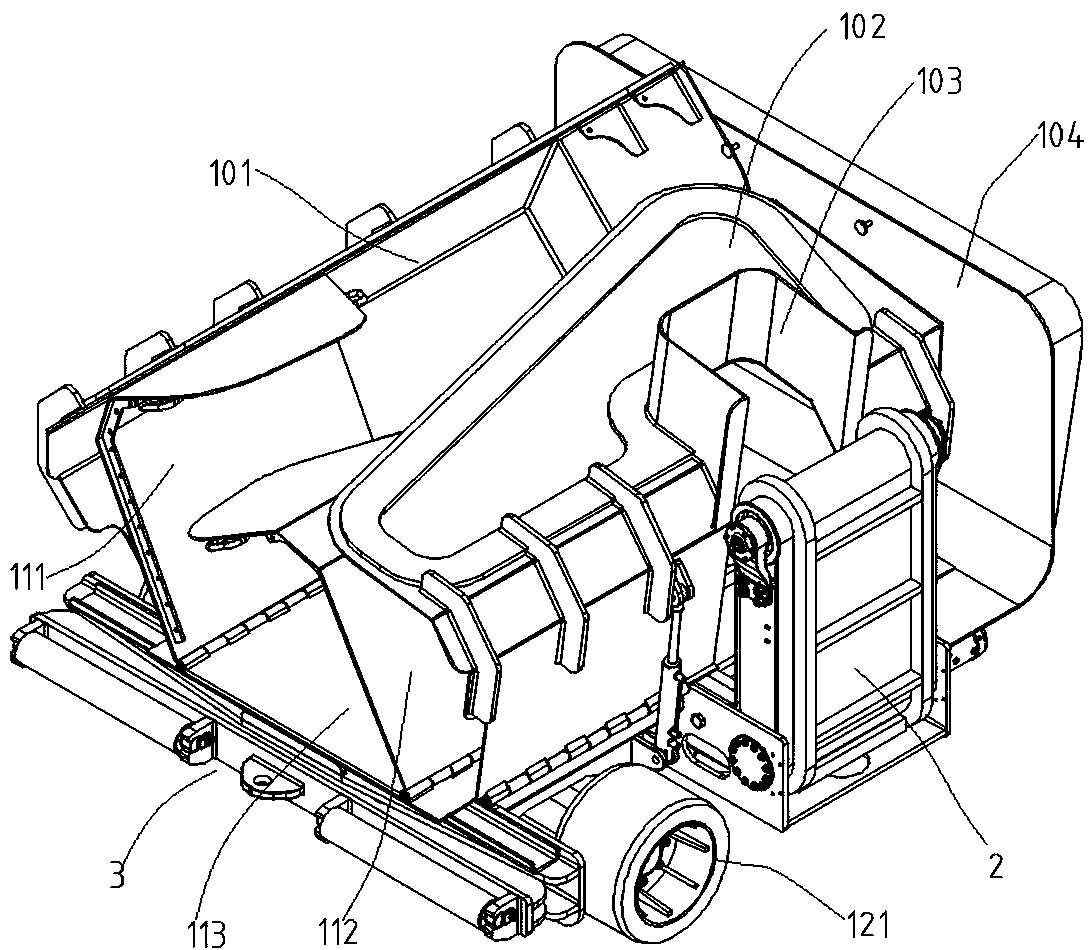

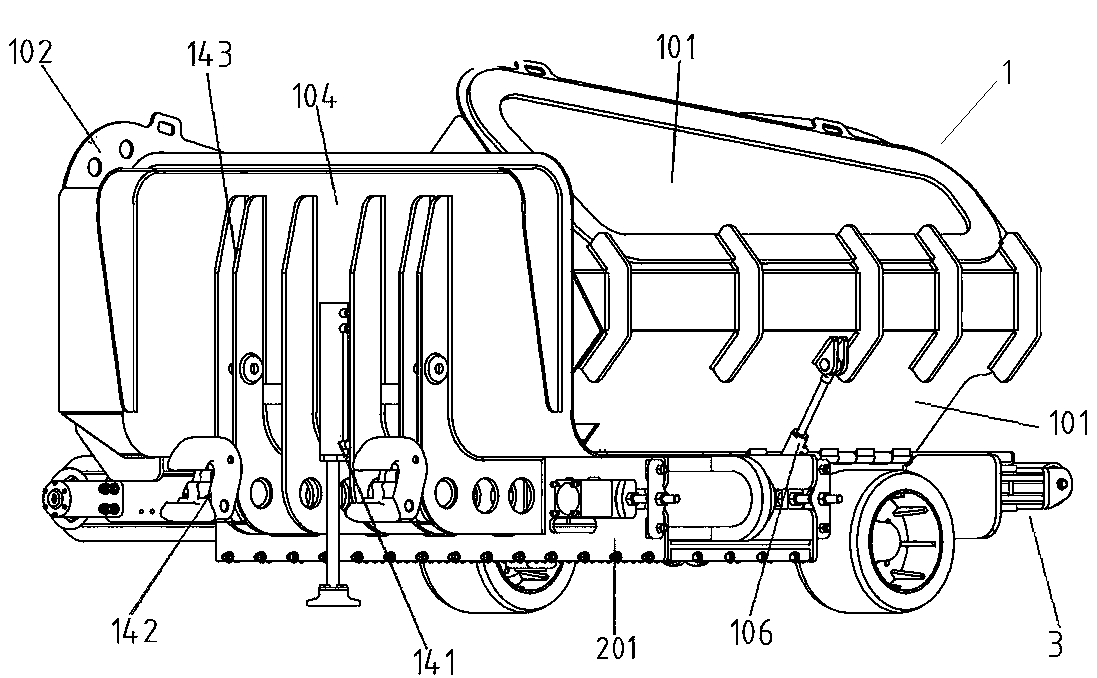

[0022] The present invention will be further explained below in conjunction with the accompanying drawings.

[0023] A hopper assembly for an engineering vehicle, comprising a plate-and-frame hopper underframe 13 and a hopper 1 arranged on the hopper underframe 13; the hopper 1 includes a left side plate 101, a right side plate 102, The rear plate 104 and the base plate on the frame 13, the base plate includes a left base plate 111, a middle base plate 113 and a right base plate 112; It is a sheet metal part with an L-shaped cross section;

[0024] The left side plate 101 and the right side plate 102 are arranged symmetrically on the hopper underframe 13, and the lower edges of the left side plate 101 and the right side plate 102 are respectively hinged on the left and right sides of the hopper underframe 13; 111 and the lower edge of the right bottom plate 112 are respectively hinged on the left and right edges of the middle bottom plate 113, and the left bottom plate 111 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com