Super-capacitor carbon producing and flushing system

A technology of supercapacitor carbon and flushing system, applied in the fields of hybrid capacitor electrodes, carbon compounds, inorganic chemistry, etc., can solve the problems of affecting the quality of activated carbon, waste of water resources, slow flushing speed, etc., achieve comprehensive and fast flushing, improve flushing quality, The effect of saving water and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

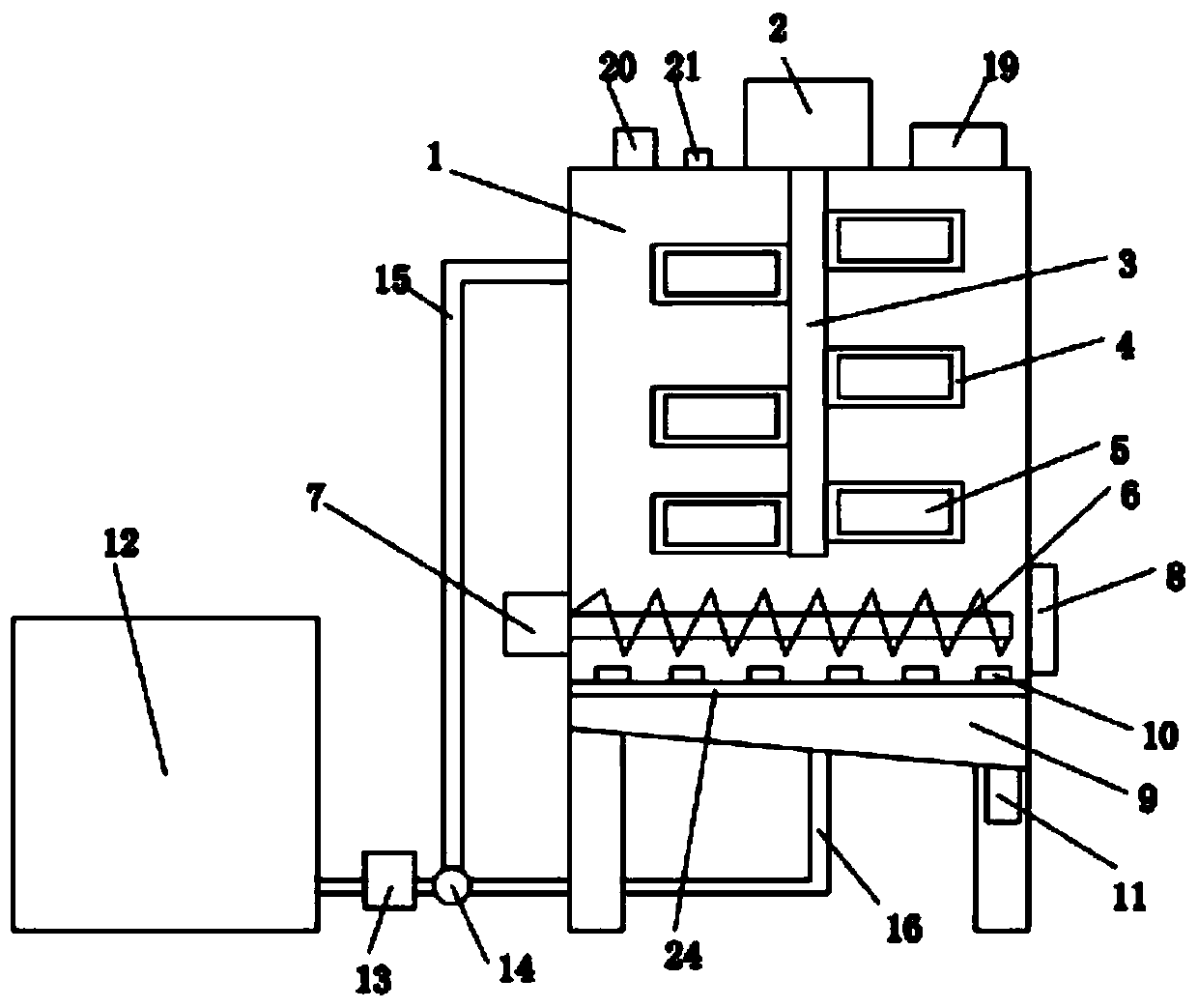

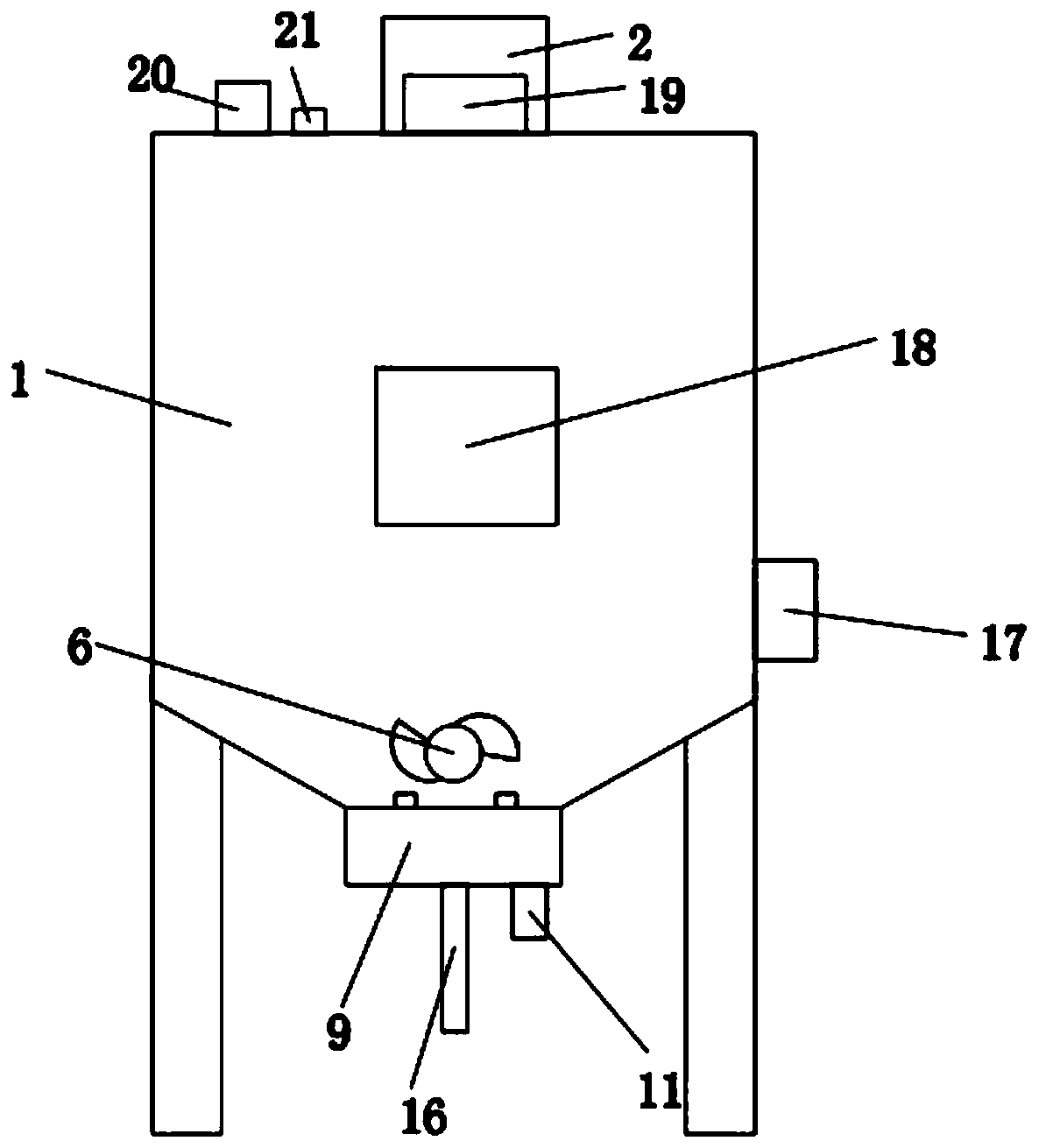

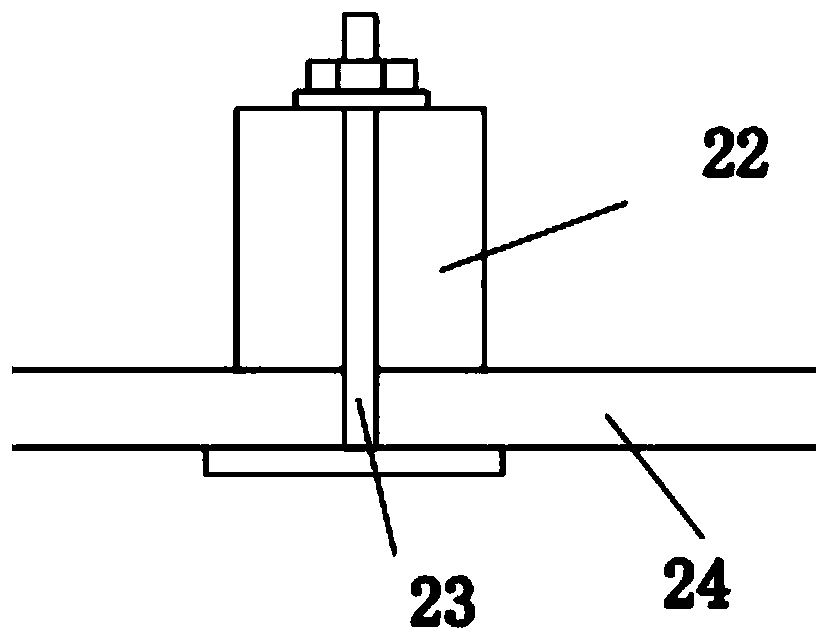

[0017] A supercapacitor carbon production flushing system, comprising a flushing tank 1 and a water tank 12 providing water to the flushing tank 1, the upper end of the flushing tank 1 is provided with a driving motor 2 and a feed port 19, and the flushing tank 1 is provided with a Drive the stirring shaft 3 matched with the motor 2, the stirring shaft 3 is provided with a pusher plate 4, the screw conveying rod 6 is arranged under the stirring shaft 3, and the outside of the washing tank 1 is respectively provided with the screw conveying rod 6. Corresponding motor 7 and discharge port 8, described screw conveyor rod 6 below is provided with partition 24, and described partition 24 is provided with filter cap 10, and described partition 24 below is provided with dirt collection tank 9, described One end of the sewage collection tank 9 is provided with a sewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com