Curing equipment for vanadium pentoxide extraction from coal cinders

A vanadium pentoxide and curing technology, which is applied in the field of vanadium pentoxide curing equipment for coal slag extraction, can solve problems such as poor continuous performance affecting material processing, and achieve the effects of avoiding mixed pollution of materials, speeding up processing progress, and uniform particles

Inactive Publication Date: 2019-06-07

张光照

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Aiming at the deficiencies of the prior art, the present invention provides a aging equipment for extracting vanadium pentoxide from coal slag, which solves the problem that poor continuity performance affects material processing in material aging processing production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

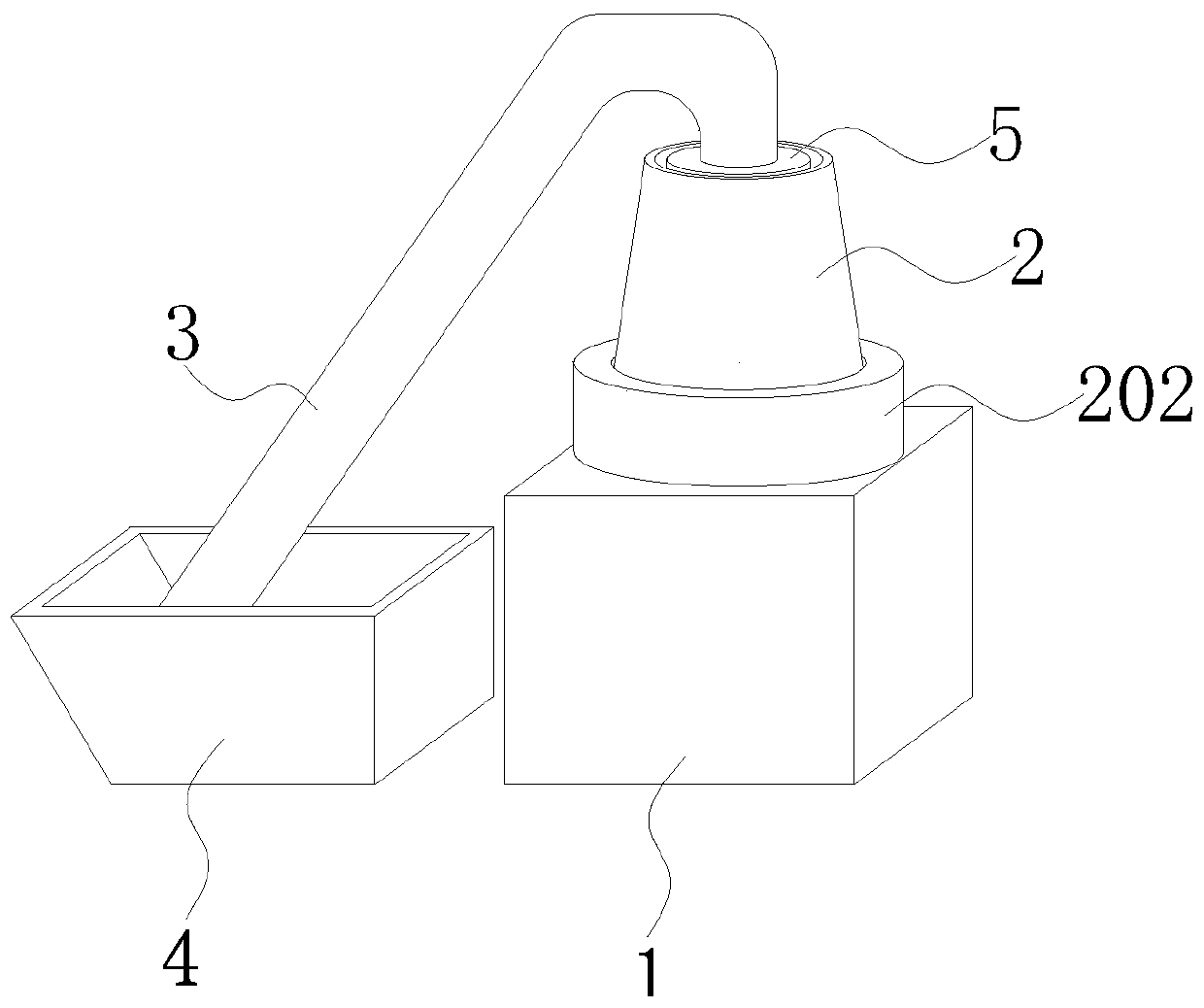

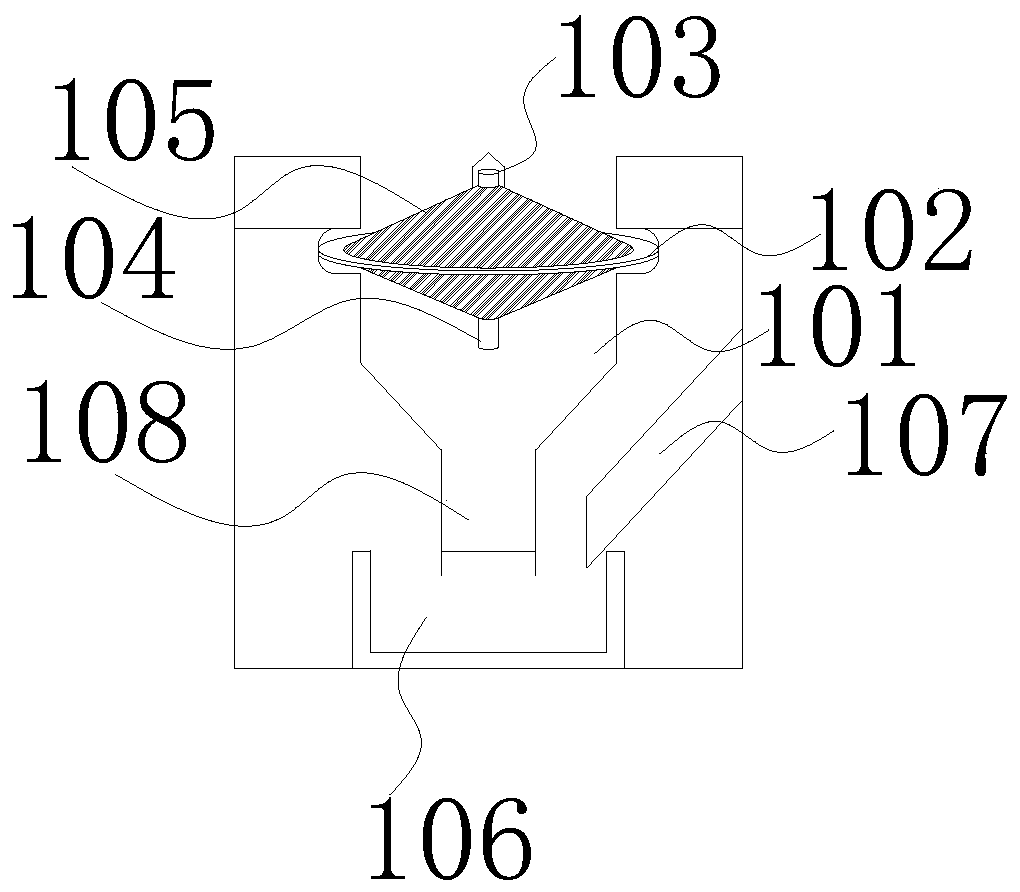

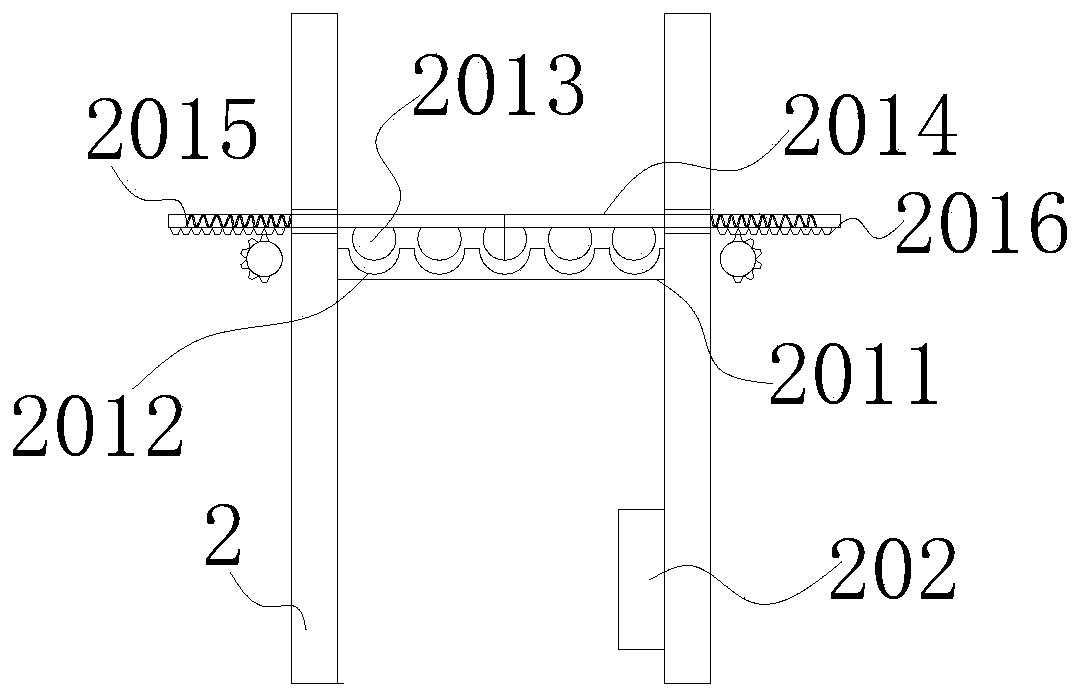

The invention discloses curing equipment for vanadium pentoxide extraction from coal cinders. The curing equipment for vanadium pentoxide extraction from the coal cinders comprises a storage box, a clinker box, a stranding cage loading machine, a feeding box and a dispersing mechanism, wherein the bottom of the clinker box and the middle portion of the top of the storage box are fixedly welded, and the stranding cage loading machine is installed on the top of the clinker box; the dispersing mechanism comprises a dispersing box, a conical cover, a dispersing shaft, dispersing blades, splittinggrooves and dispersing grooves, wherein an outer ring of the dispersing box is fixedly installed on the top of an inner cavity of the clinker box through bolts, the splitting grooves are formed in thetop of the dispersing box at equal intervals, the dispersing grooves are formed in the bottom of an inner wall of the dispersing box at equal intervals, and triangular boards are arranged on one surface of each dispersing blade at equal intervals. According to the curing equipment for vanadium pentoxide extraction from the coal cinders, a curing process of multiple dispersion and crushing is adopted, and in the overall curing process, materials do not accumulate, so that the material is evenly heated, and the curing quality is improved; and meanwhile, crushing operation can be conducted on massive materials, so that the processing process of material curing is accelerated.

Description

technical field [0001] The invention relates to the technical field of ripening of chemical materials, in particular to a slag extraction vanadium pentoxide ripening device. Background technique [0002] At present, with the continuous development and progress of the industrial production industry, in the existing technology, most of the materials are stirred by external force. Under the action of mechanical force, the materials are rubbed against each other under high pressure, and the heat generated by the friction force is used to achieve the aging of the materials. However, this processing method has the disadvantages of low yield, high cost and difficulty in controlling the degree of maturation. [0003] For the shortcomings of the traditional solutions, there are also many solutions at present. For example, the Chinese patent discloses "a material curing machine" (patent number: CN206462380U), which includes a steaming cylinder, the steaming cylinder is provided with a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01G31/02

Inventor 张光照

Owner 张光照

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com