A deep shaft support structure and construction method

A technology of support structure and construction method, which is applied in well sinking, earthwork drilling, vertical shaft equipment, etc., can solve the impact of ground pressure disaster, the failure of reasonable adjustment and release of concentrated stress of surrounding rock, and the increase of engineering cost and construction period of support structure. and other problems, to achieve the effect of uniform force distribution and reduction of bending stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

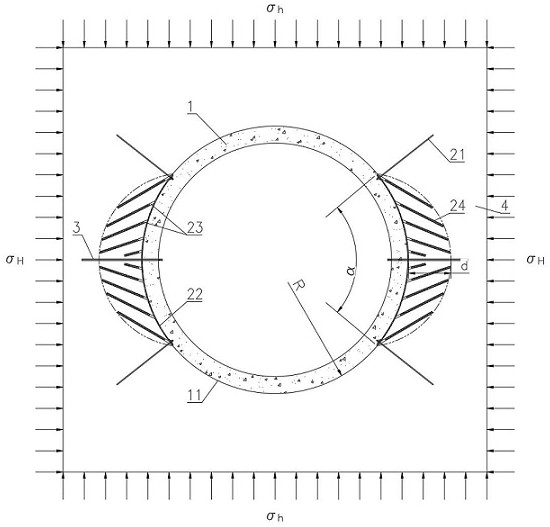

[0034] Such as figure 1 As shown, the deep shaft support structure provided by this embodiment is used for constructing a shaft excavation section 11 on the surrounding rock 4 and pouring to form the support of the shaft wall 1 . The deep shaft support structure includes anchor net fixing area, drilling group 23 and static breaking agent 24 . The anchor net fixing area is formed by the maximum horizontal stress σ on the shaft excavation section 11 H On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com