Eccentric-swing gear reducer

A technology of gear reduction and eccentric swing, applied in the direction of gear transmission, transmission, gear lubrication/cooling, etc., can solve the problems of torque transmission loss, heat generation, wear, etc., achieve high efficiency and long life, reduce heat generation, and be good The effect of the lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following describes the present invention in detail with reference to the drawings and specific embodiments.

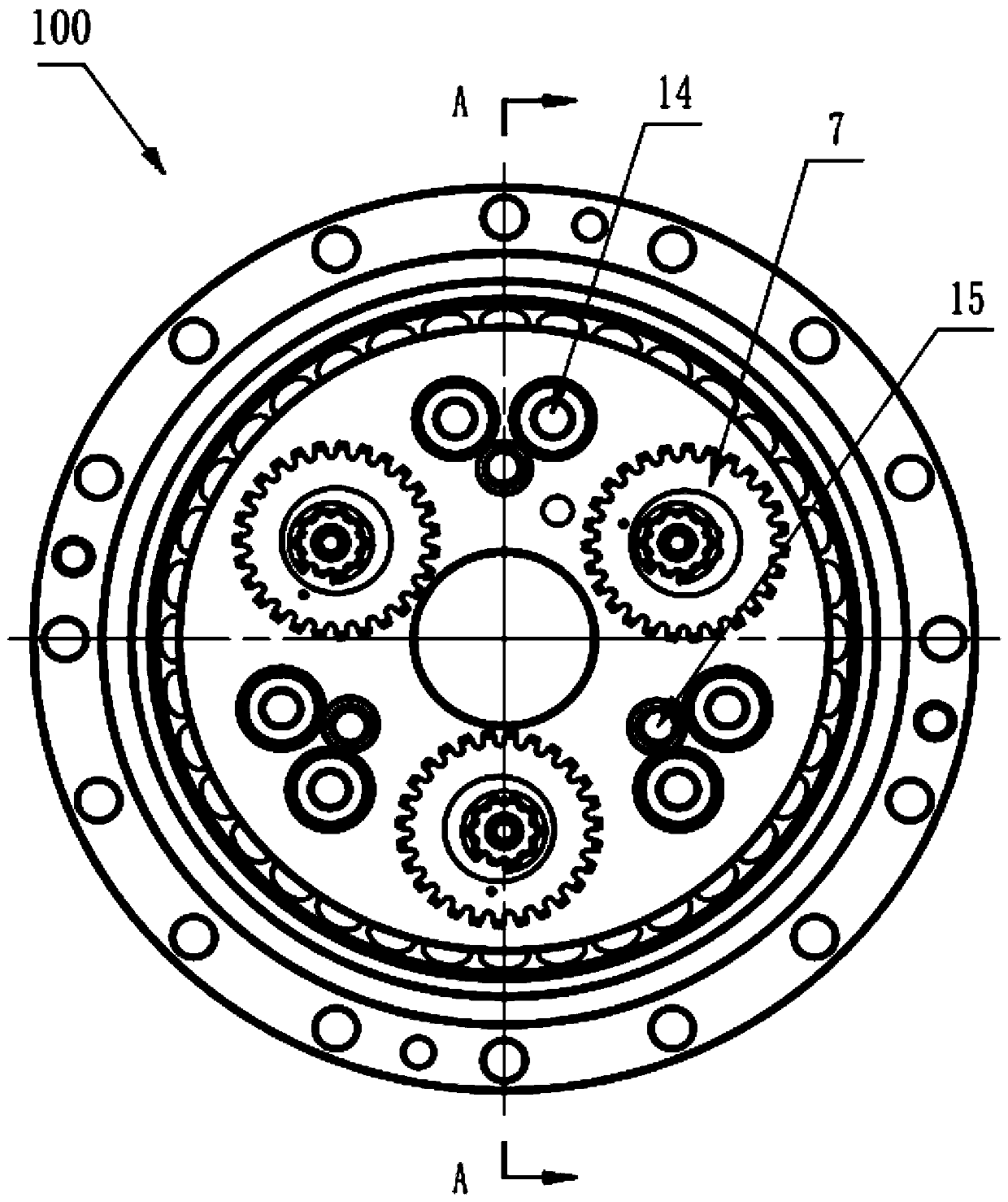

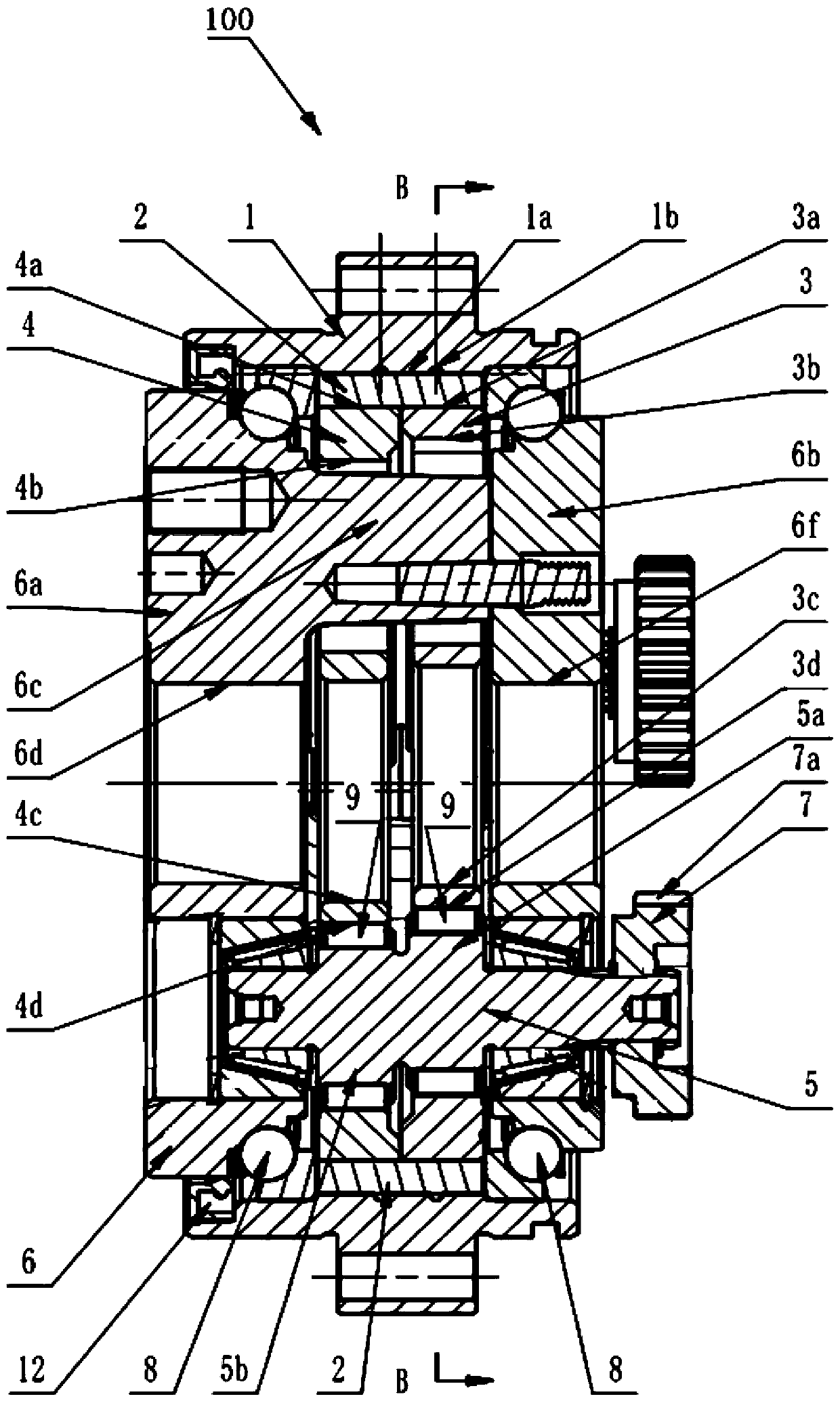

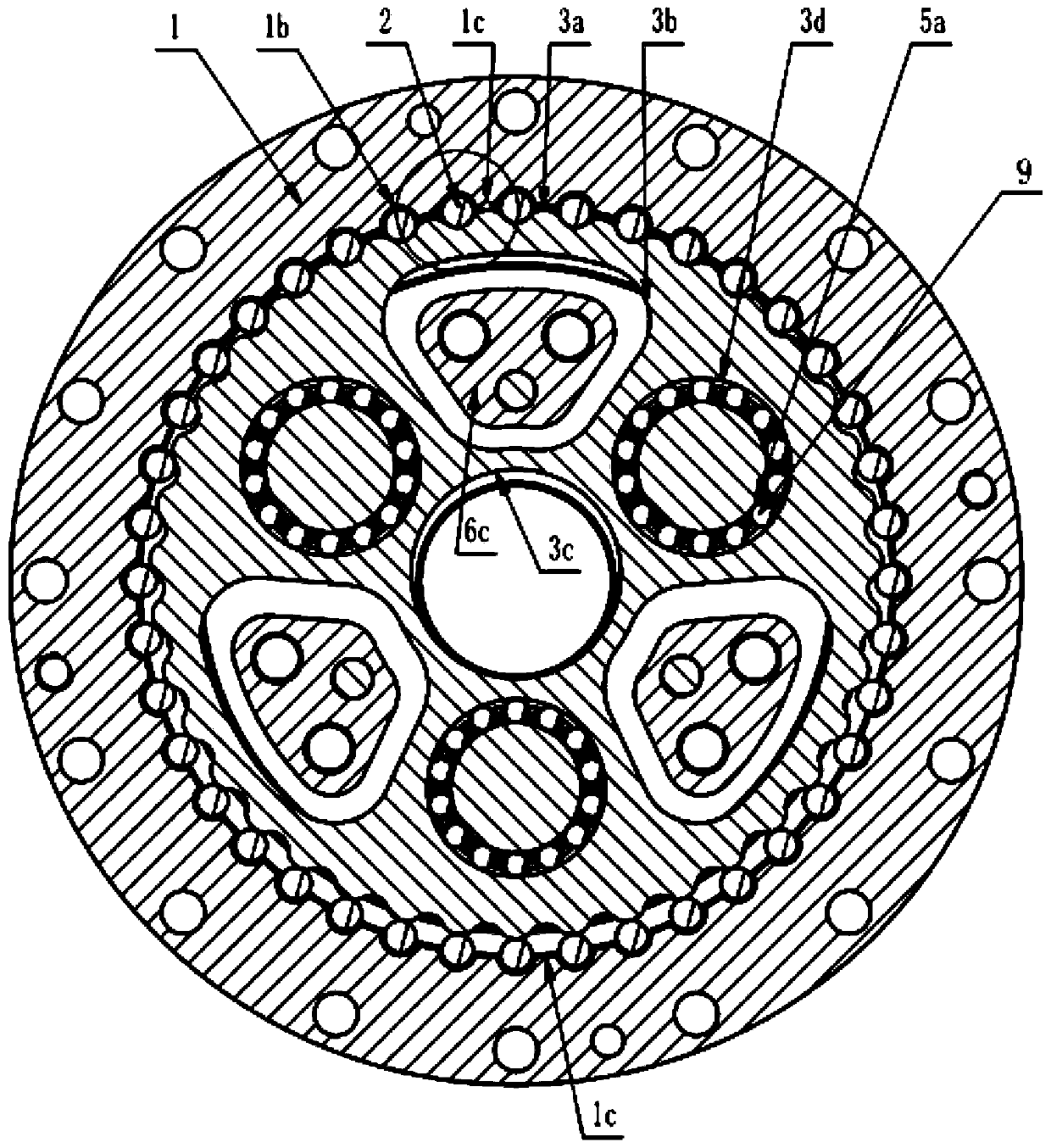

[0022] Such as Figure 1 to Figure 4 As shown, an eccentric swing type gear reducer 100 includes: a pin gear housing 1, a pin gear 2, a swing gear, a planet carrier 6, a crank shaft 5, a planet gear 7, a main bearing 8 and a crank bearing 9.

[0023] The eccentric swing type gear reduction device 100 realizes transmission with a certain speed ratio between two transmission members. The planetary gear 7 transmission stage and the swing gear transmission stage rotate at a certain speed ratio.

[0024] As a specific embodiment, the planet carrier 6 includes: an output carrier 6a and a supporting flange 6b. The support flange 6b is fixed to the output frame 6a so that the support flange 6b and the output frame 6a form a whole. The output frame 6a is provided with a plurality of shaft portions 6c. The shaft portion 6c is connected to the supporting flange 6b. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com