Expansion valve

A technology for expansion valves and valve bodies, applied in valve details, safety valves, balance valves, etc., can solve the problems of complex process and high cost, and achieve the effect of reducing the response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

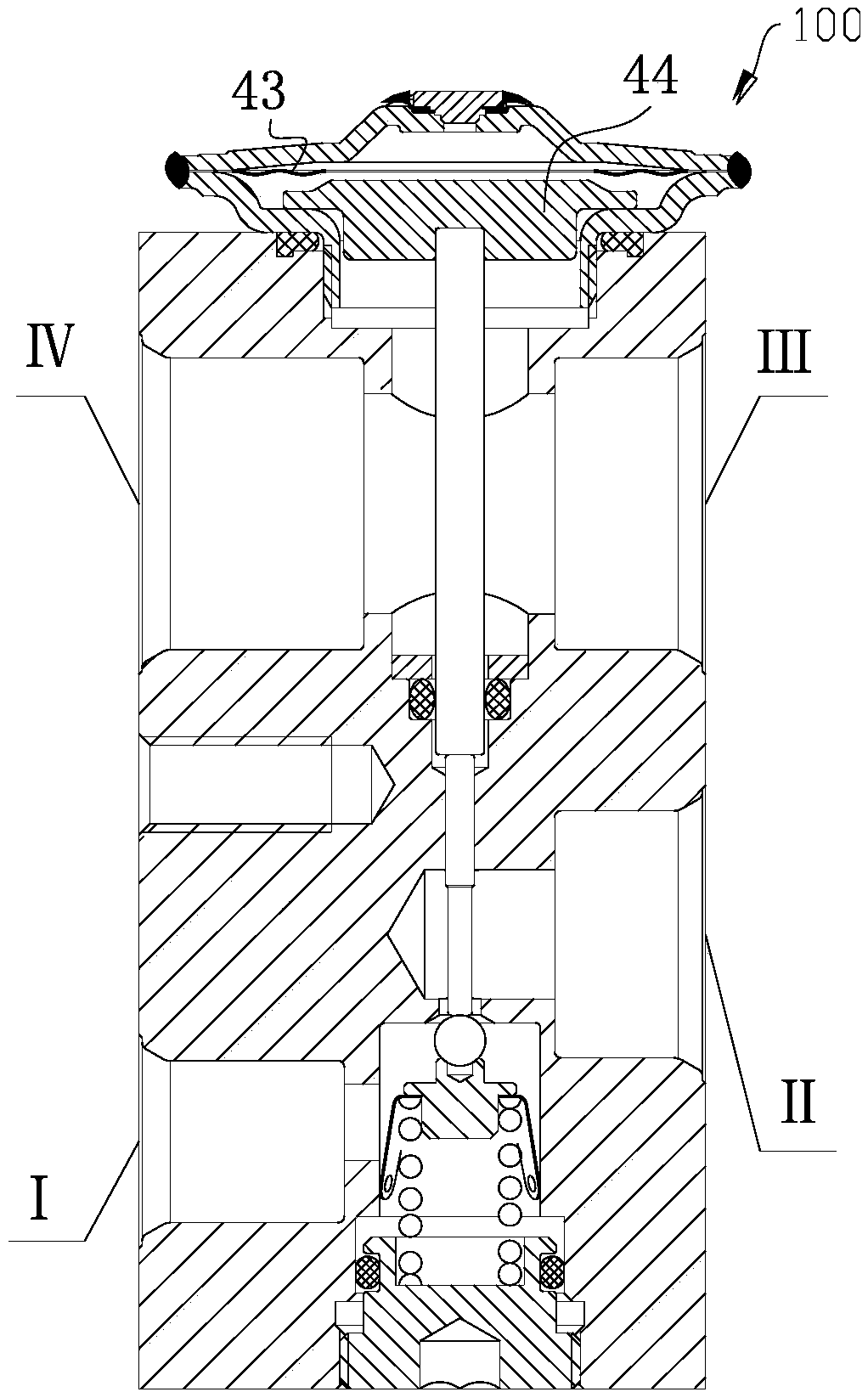

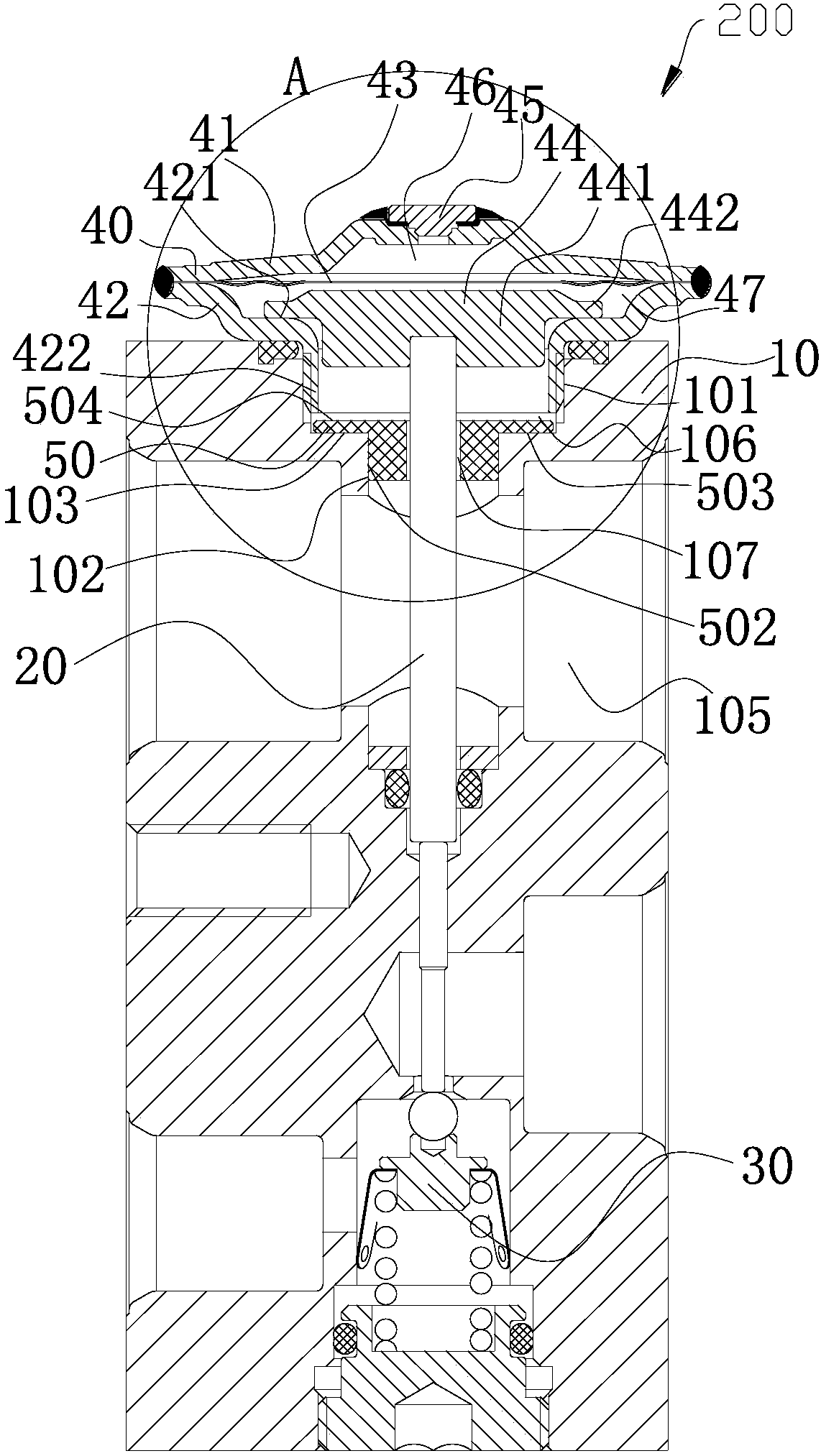

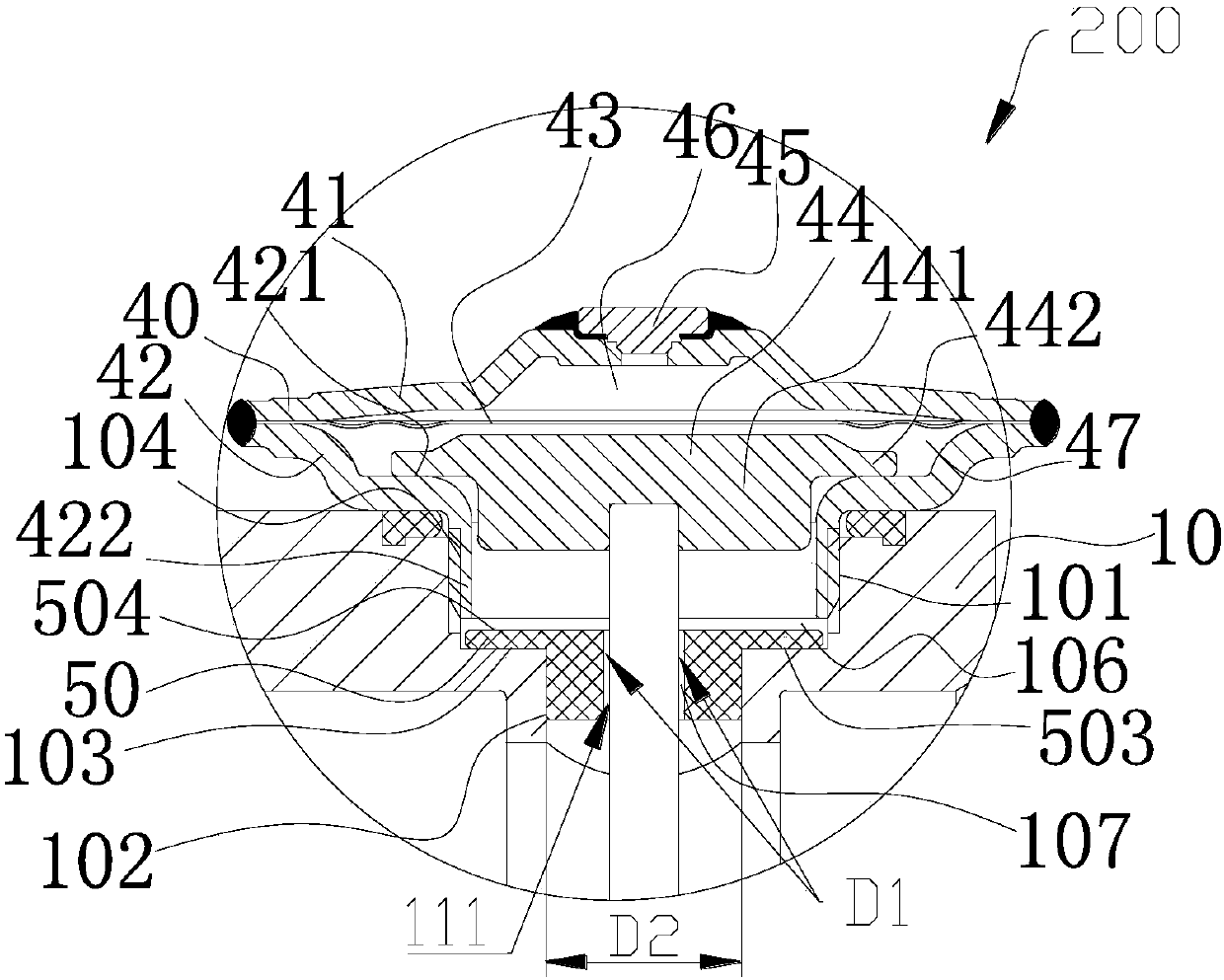

[0023] refer to figure 2 , image 3 and Figure 4 , the expansion valve 200 includes an air box head 40, a valve body 10, a transmission rod 20, and an adjustment seat 30. The air box head 40 is fixed on one side of the valve body 10, the adjustment seat 30 is fixed on the other side of the valve body 10, and the transmission rod 20 is located at Inside the valve body 10 , one end of the transmission rod 20 is fixed or space-limited with the gas tank head 40 , and the other end of the transmission rod 20 is fixed or space-limited with the adjustment seat 30 .

[0024] Air box head 40 comprises air box cover 41, air box seat 42, diaphragm 43, driving plate 44 and sealing plug 45, and diaphragm 43 is positioned between air box cover 41 and air box seat 42, and air box cover 41 and air box The box seat 42 is fixedly arranged, such as by welding. The inside of the gas box head 40 includes a closed chamber 46 and a pressure equalization chamber 47. The diaphragm 43 separates the...

Embodiment 2

[0048] refer to Figure 9 and Figure 10 , Figure 9 A schematic cross-sectional view of the expansion valve 300 is shown. The structure of the expansion valve 300 is roughly the same as that of the expansion valve 200, and its structure can be referred to above.

[0049] The expansion valve 300 includes an isolator 50"', the isolator 50"' includes a through hole 501, the through hole 501 is located at the center of the isolator 50"', and the transmission rod 20 passes through the through hole 501.

[0050] The valve body 10 includes an accommodating cavity 101 , at least part of the air box head 40 is located in the accommodating cavity 101 , and the air box seat 42 and the valve body 10 form a wall portion of the accommodating cavity 101 to be sealed. The valve body 10 includes a second wall portion 102 and a first wall portion 103, the second wall portion 102 and the first wall portion 103 form a stepped shape, wherein the second wall portion 102 generally extends along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com