A method for measuring the pib factor of laser far-field beam quality

A technology of beam quality and measurement method, applied in the field of laser parameter measurement, can solve the problem of inability to obtain the PIV factor in real time, and achieve the effect of real-time measurement, avoiding time synchronization and data fusion, and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

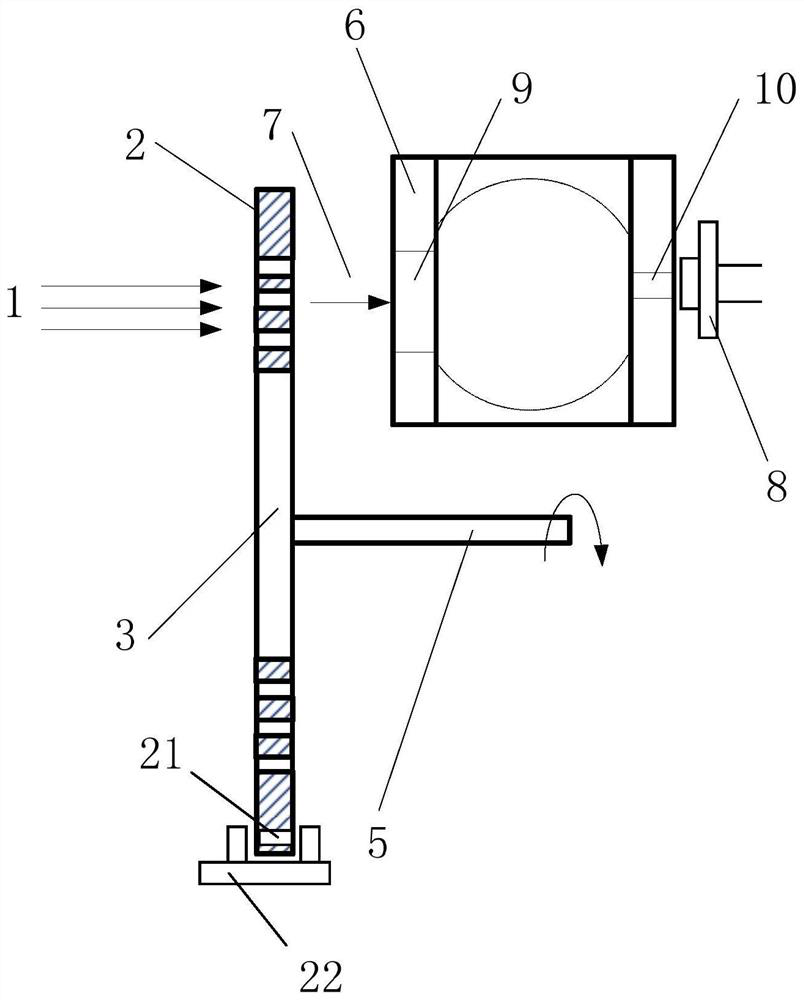

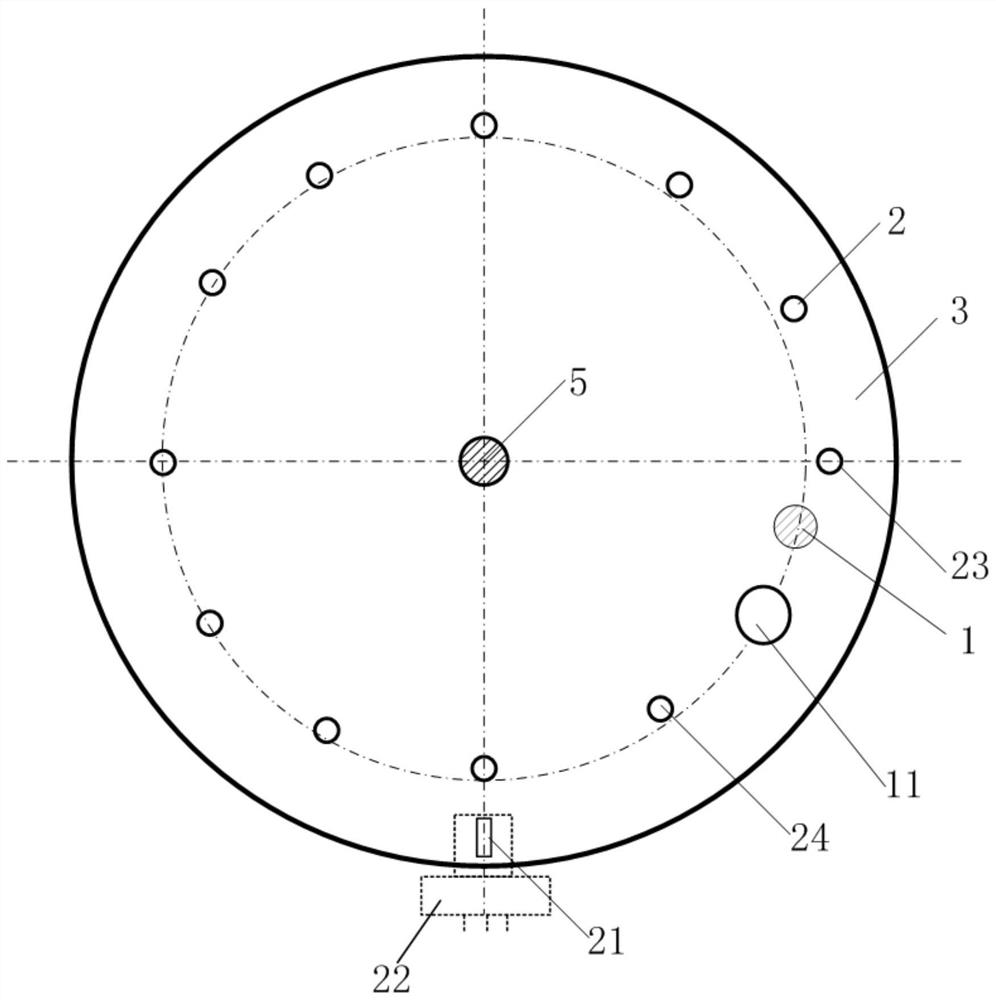

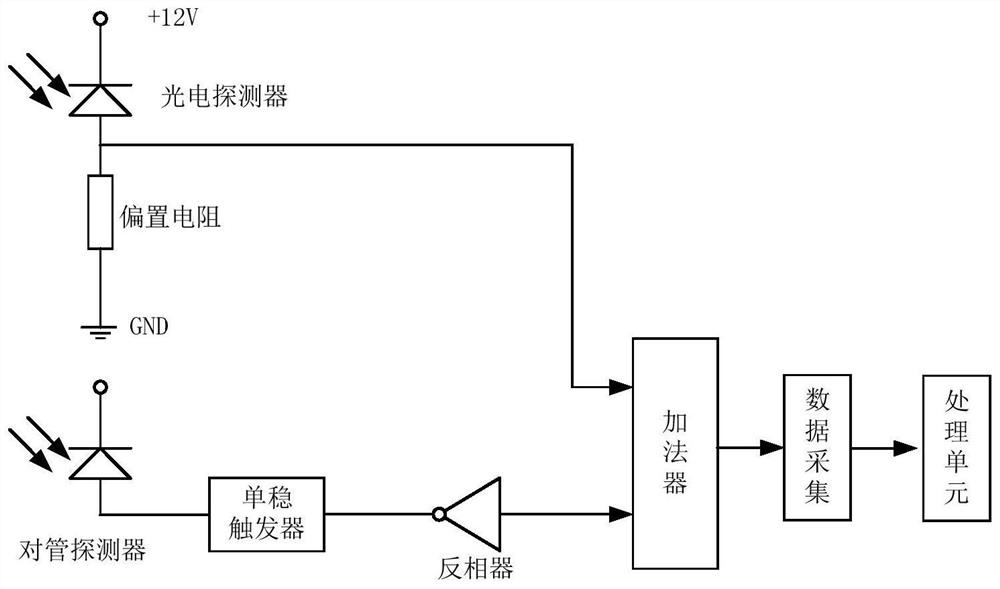

[0037] like Figure 1-3 As shown, the measuring device of the laser far-field beam quality PIB factor of the present invention includes a scanning disk 3 rotating at a high speed around the central axis 5, a photoelectric detection unit, a detection circuit and a casing (not shown in the figure); the detection circuit includes an addition device, data acquisition unit, processing unit;

[0038] The scanning disk 3 is provided with a set of sampling holes 2 and a transmission hole 11 . The far-field laser beam 1 to be measured passes through the sampling holes 2 and the transmission hole 11 and is incident on the photodetection unit on the other side of the scanning disk 3 . The sampling holes 2 are evenly spaced in involutes around the central axis 5. When the scanning disk 3 rotates, the sampling holes 2 realize full-spot scanning sampling of the far-field laser beam 1 to be measured.

[0039] The photoelectric detection unit adopts the method of arranging the fast-response ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com