Preparation method of chromium propionate

A technology of chromium propionate and n-propionate, which is applied in the field of preparation of chromium propionate, can solve problems such as unfavorable industrial continuous production, large occupational health risks, and need for post-processing, so as to be beneficial to industrial continuous production and facilitate industrial production , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

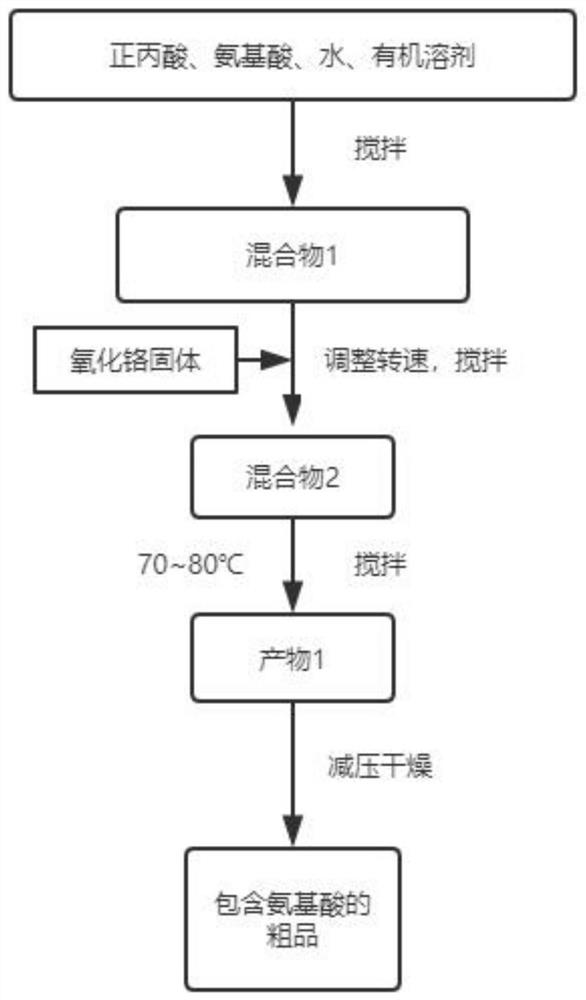

Method used

Image

Examples

Embodiment 1

[0025]Add n-propionic acid (1110g, 15mol), lysine (584g, 4mol), 15L water and 1L ethanol to the reaction kettle, stir until the mixture is uniform, add chromium oxide solid (456g, 3mol) to it, adjust the speed to 500r / min, heat to 70-80°C with stirring, and react until there is no solid residue. The reaction time is 2 hours.

[0026]After the reaction, it was dried under reduced pressure to obtain a crude product containing lysine. The yield was determined by measuring the content of chromium in the product, and the yield of chromium propionate was determined to be 98.7%.

Embodiment 2

[0028]Add n-propionic acid (1110g, 15mol), lysine (584g, 4mol), 15L of water to the reaction kettle, stir until the mixture is uniform, add chromium oxide solid (456g, 3mol) to it, adjust the speed to 500r / min and stir Heat to 70-80°C, and react until no solid remains. The reaction time is 3 hours.

[0029]After the reaction, the product was dried under reduced pressure to obtain a crude product containing lysine. The yield was determined by measuring the content of chromium in the product. The yield of chromium propionate was 87.8%.

Embodiment 3

[0031]The influence of different initiators on the preparation of chromium propionate:

[0032]Add n-propionic acid (1110g, 15mol), initiator 4mol, 15L water and 1L ethanol to the reaction kettle, stir until the mixture is uniform, add chromium oxide solid (456g, 3mol) to it, adjust the speed to 500r / min, and stir. Heat to 70-80°C and react until no solid remains.

[0033]After the reaction, the product was dried under reduced pressure to obtain a crude product containing the initiator. The yield was determined by measuring the content of chromium in the product.

[0034]The specific yield and reaction time are as follows:

[0035] Group Initiator Reaction time Yield 1Lysine 2h98.7% 2Glutamine 4h78.6% 3Asparagine 4h66.7% 4Ethylenediamine 6h90.4% 5Blank group 6h (with solid residue) 50.4%

[0036]It can be concluded from the above that, compared to adding glutamine, asparagine and ethylenediamine as initiators, the yield of adding lysine as initiator is higher, so using lysine as initiator is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com