Linear motor structure for linear compressor

A technology of linear motors and linear compressors, applied in the directions of machines/engines, electric components, electromechanical devices, etc., can solve problems such as errors, uneven elongation of pure iron sheets, and reduced motor efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

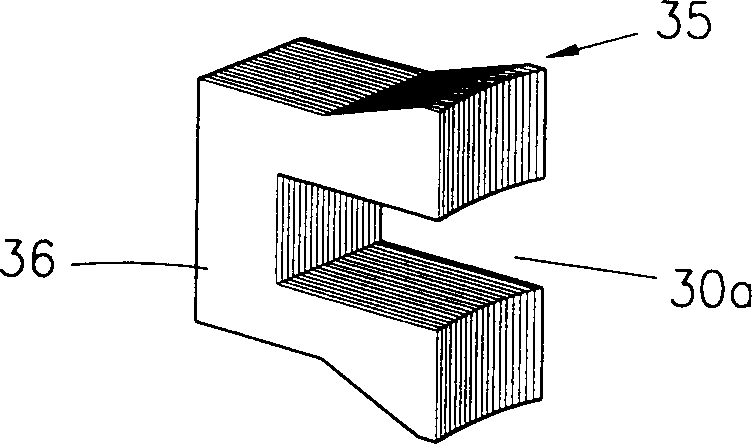

[0049] Figure 10A and Figure 10B Shown in the lamination device of the linear compressor according to the present invention, wherein the lamination 100 has many pure iron sheets arranged along the radial direction. Figure 11A and Figure 11B It shows the lamination device of the present invention, wherein the lamination 100 is fixed by the upper fixing member 130 .

[0050] Specifically, protruding portions 120 are formed on concentric circles of pure iron sheets arranged in the radial direction, and caulking grooves 120a are formed on each protruding portion.

[0051] An upper fixing member 130 made of a non-magnetic material or a material having high electrical resistance is filled in the caulking groove 120a of each protruding portion 120 .

[0052] In addition, if Figure 12 As shown, the fastener on one side of the lamination 100 supported by an inner coil spring (not shown in the figure) can be made into a lower fastener 200, the fixing ring 200a of the lower fasten...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap