Rock three-point bending fixture for size effect tests

A three-point bending and size effect technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems such as the inability to meet the test requirements of small-sized specimens, the large size of the support rolling and the pressing edge, and the inability to meet the bending test at the same time. To achieve the effect of easy disassembly, material saving and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

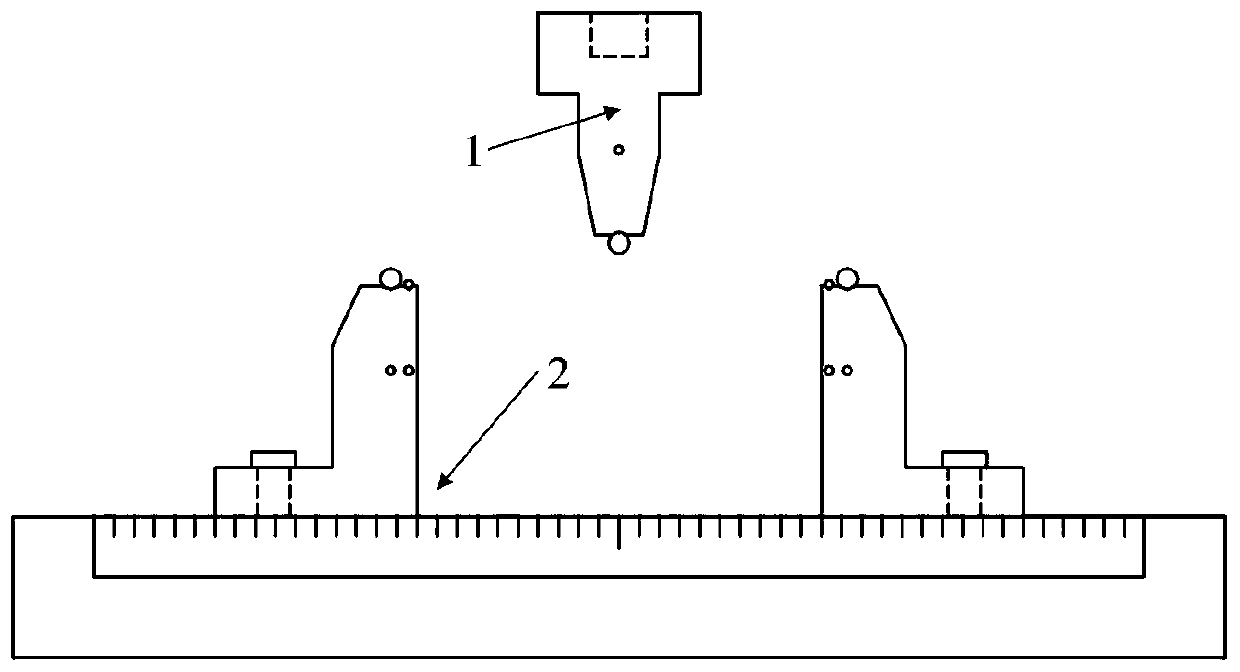

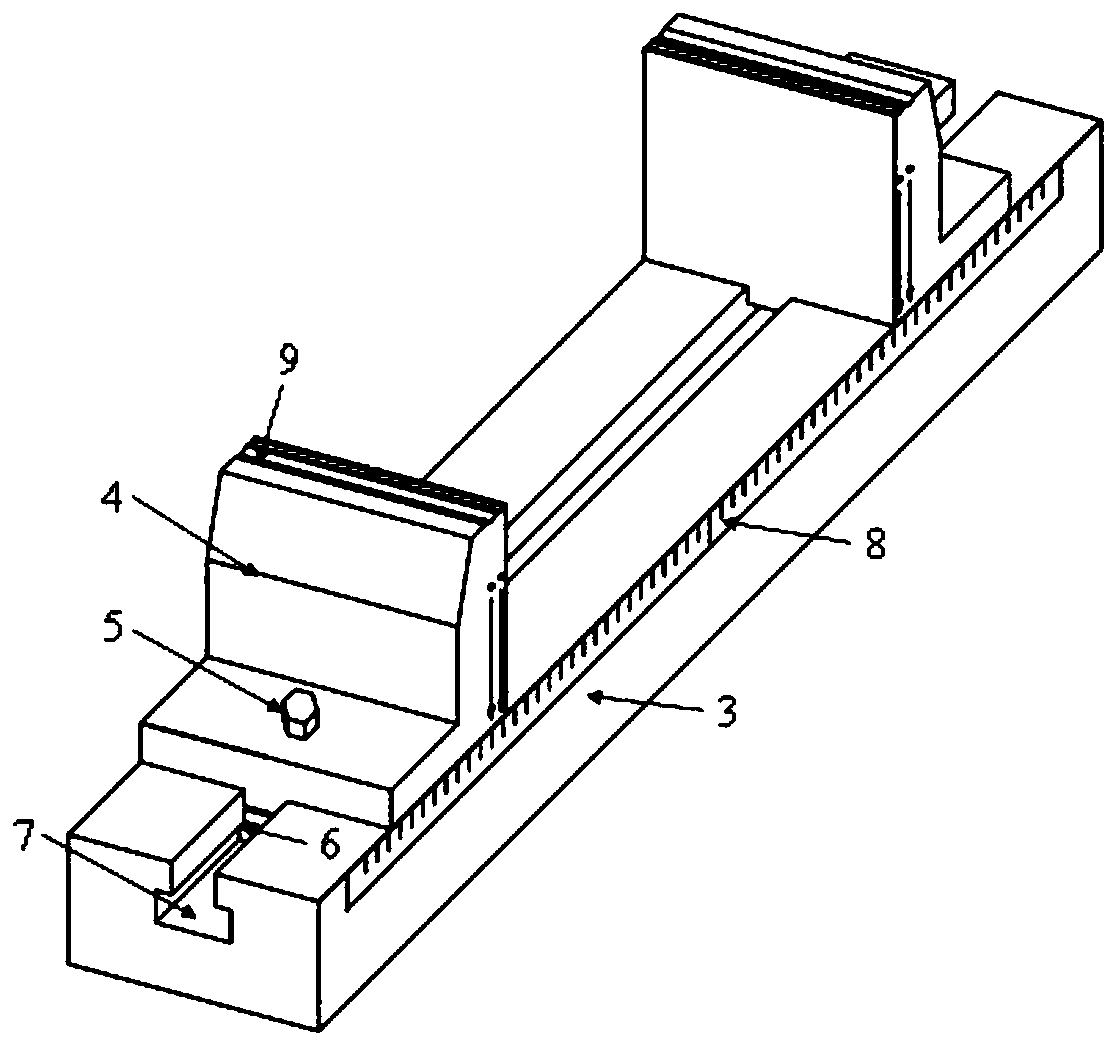

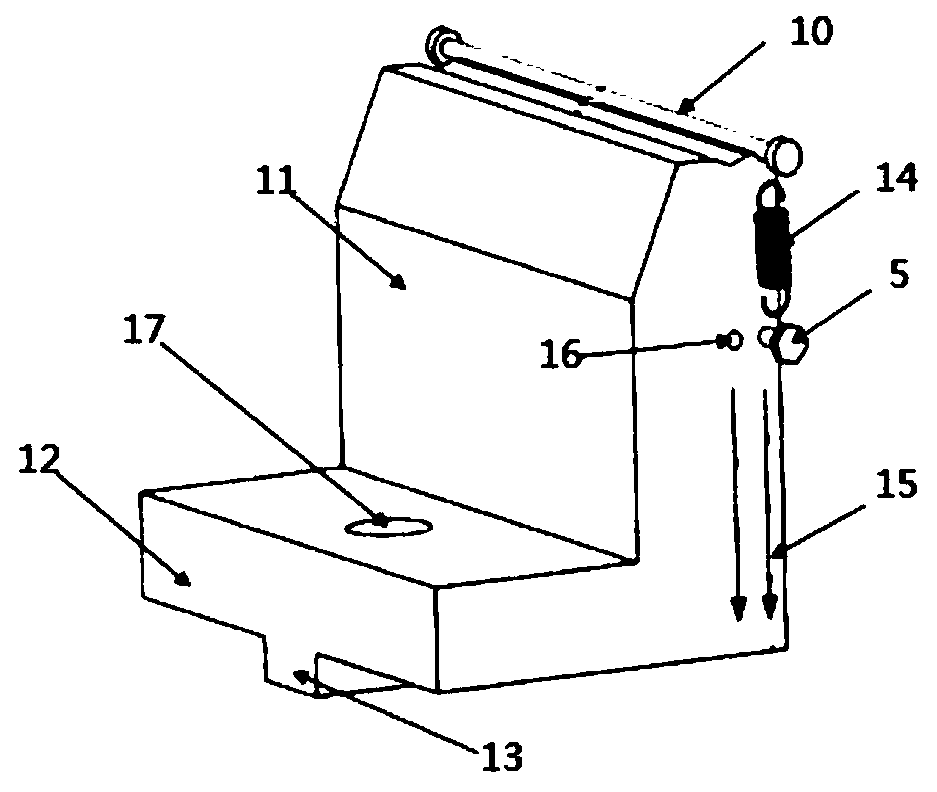

[0033] Such as Figure 1-7 As shown, this embodiment is a further description of the principle introduction and specific implementation of a rock three-point bending fixture for size effect testing of the present invention.

[0034] Such as figure 1 As shown, this embodiment provides a rock three-point bending fixture for size effect testing, including an indenter part 1 and a support part 2 arranged below the indenter part 1, and the indenter part 1 includes an indenter body 18 and Pressure roller 19, such as Figure 5 As shown, a screw hole 16 is provided at the center of the top of the indenter body 18, and the screw hole 16 has its own thread, which matches the screw rod provided by the sensor of the testing machine, so as to ensure that the indenter can transmit the load evenly. The pressure head body 18 selects high-strength 40Cr steel for use, and the pressure roller 19 selects high-strength, high hardness and high wear-resistant bearing steel for use. The pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com