Novel automatic trace sample adding device

A micro-sample addition and automatic technology, applied in the direction of analytical materials, instruments, etc., can solve the problems of lack of standardization and standardized operation management, uneven technical level of operators, poor repeatability and consistency of sample addition, etc., to achieve standardized sample addition. Standard operation, simple structure, and the effect of avoiding respiratory diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

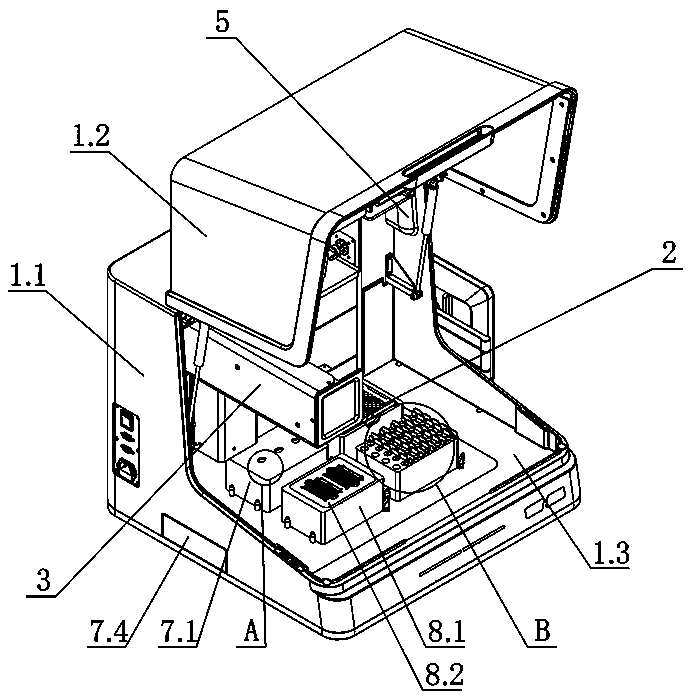

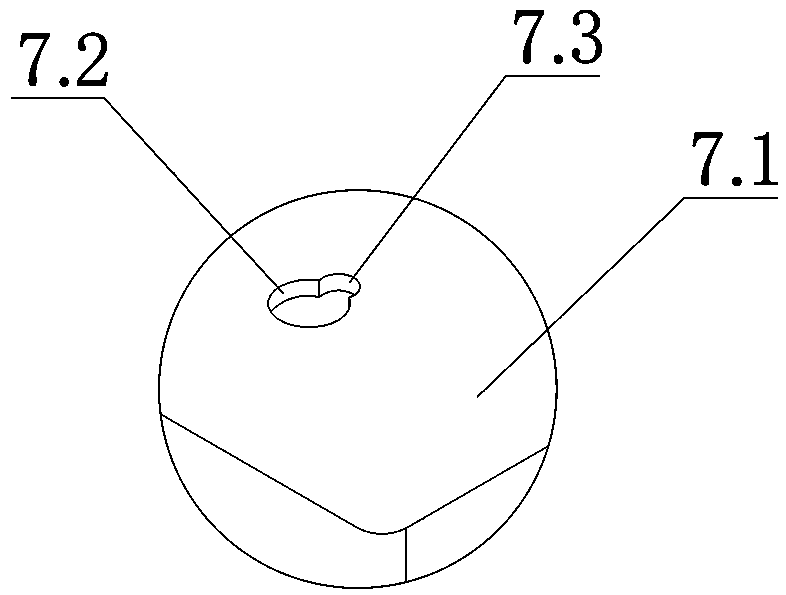

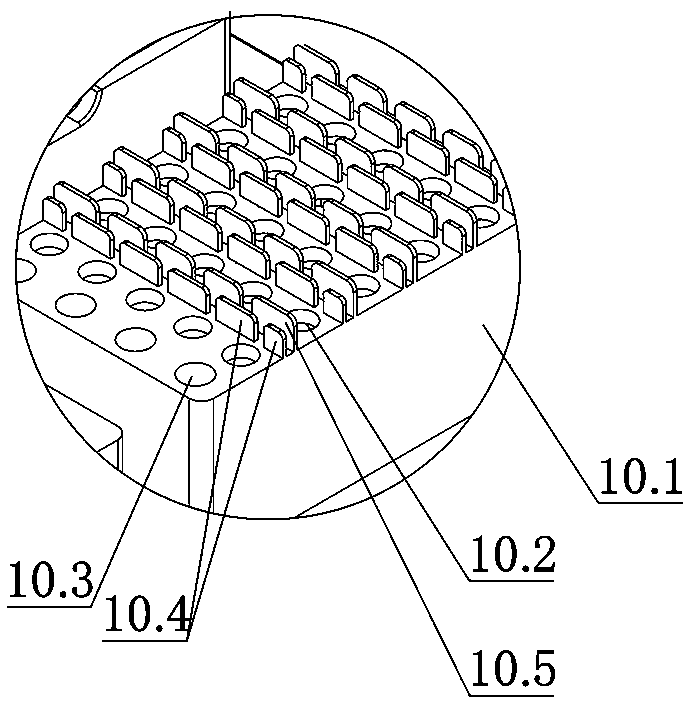

[0034] Such as figure 1 , 4 As shown in , 5, the novel automatic micro-sampling device of the present invention comprises a housing 1.2 hinged with an outer flip cover 1.1, a tip storage unit 2 is arranged at intervals on the horizontal platform 1.3 of the housing 1.2, and a discarded tip is recovered. The tip recovery unit, the sample storage unit for containing samples and reagents, and the target plate carrying unit for carrying the target plate and heating the reagents in the target plate, the tip recovery unit and the tip storage unit 2 are arranged on the horizontal platform 1.3 at intervals At the inner end, the target plate carrying unit and the gun tip recovery unit are arranged at intervals front and rear, and the sample storage unit and the gun tip storage unit 2 are arranged at intervals in front and rear; a pipetting pump 4 driven by a three-dimensional drive mechanism 3 is arranged above the horizontal platform 1.3; The lower part of the back plate of the housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com