Device and method for simulating forces in different areas of arched tunnel

A tunnel and area technology is applied in the field of devices for simulating stress in different regions of an arched tunnel, which can solve the problem that the mechanical characteristics and related laws of the fluid-filled lining support structure of the arched tunnel cannot be measured truly, and achieve the Uniform, uniform force and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

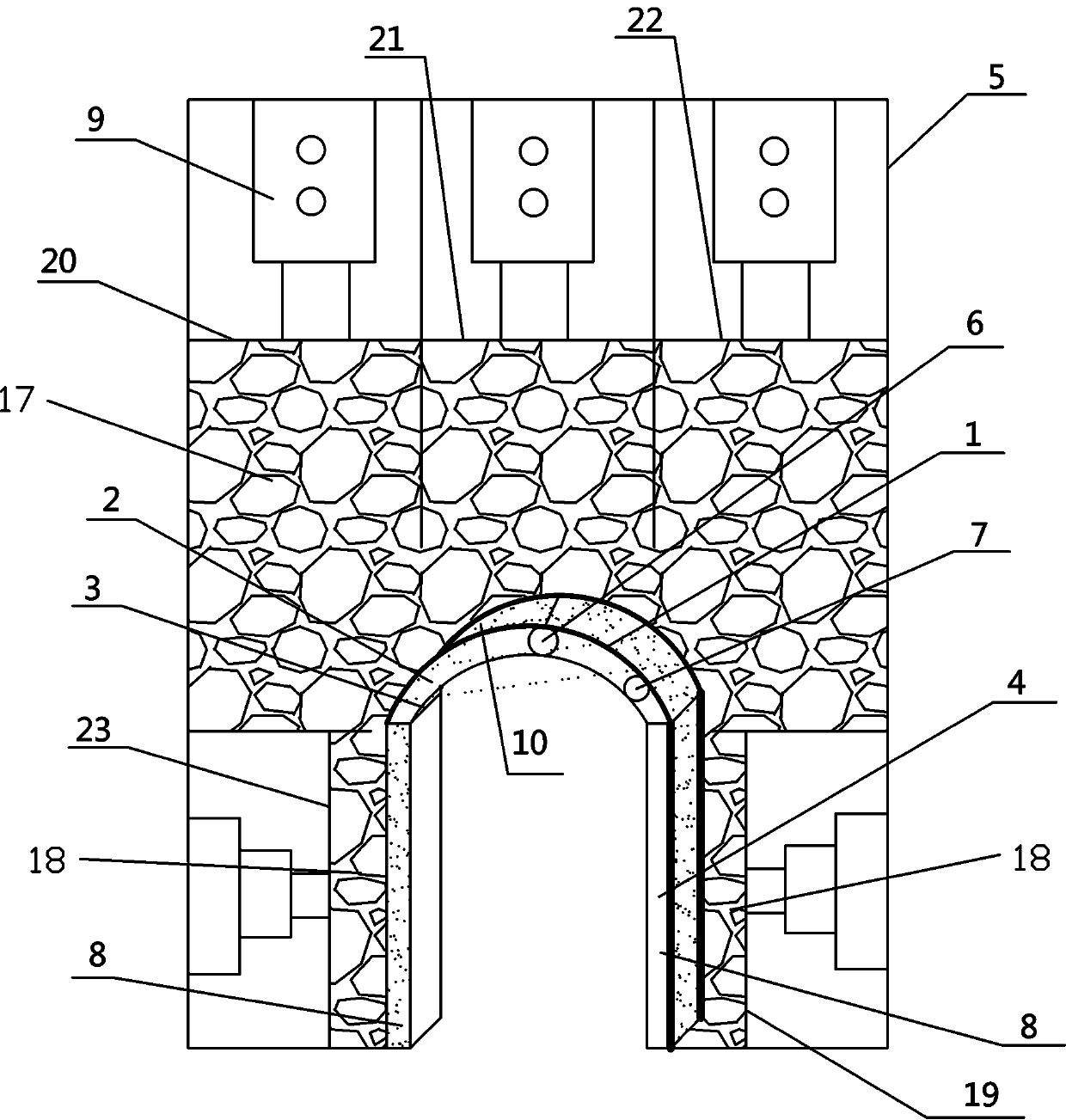

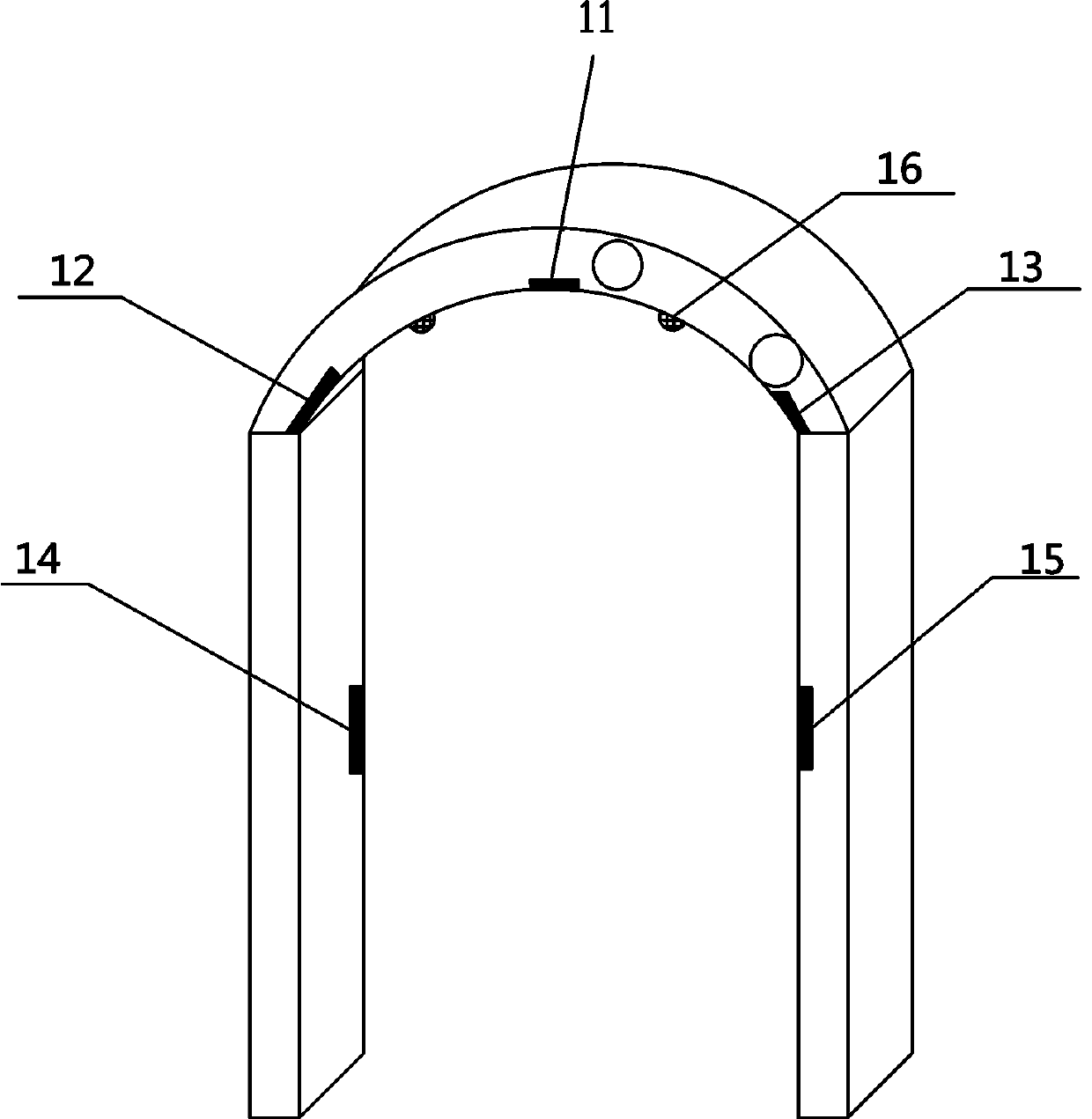

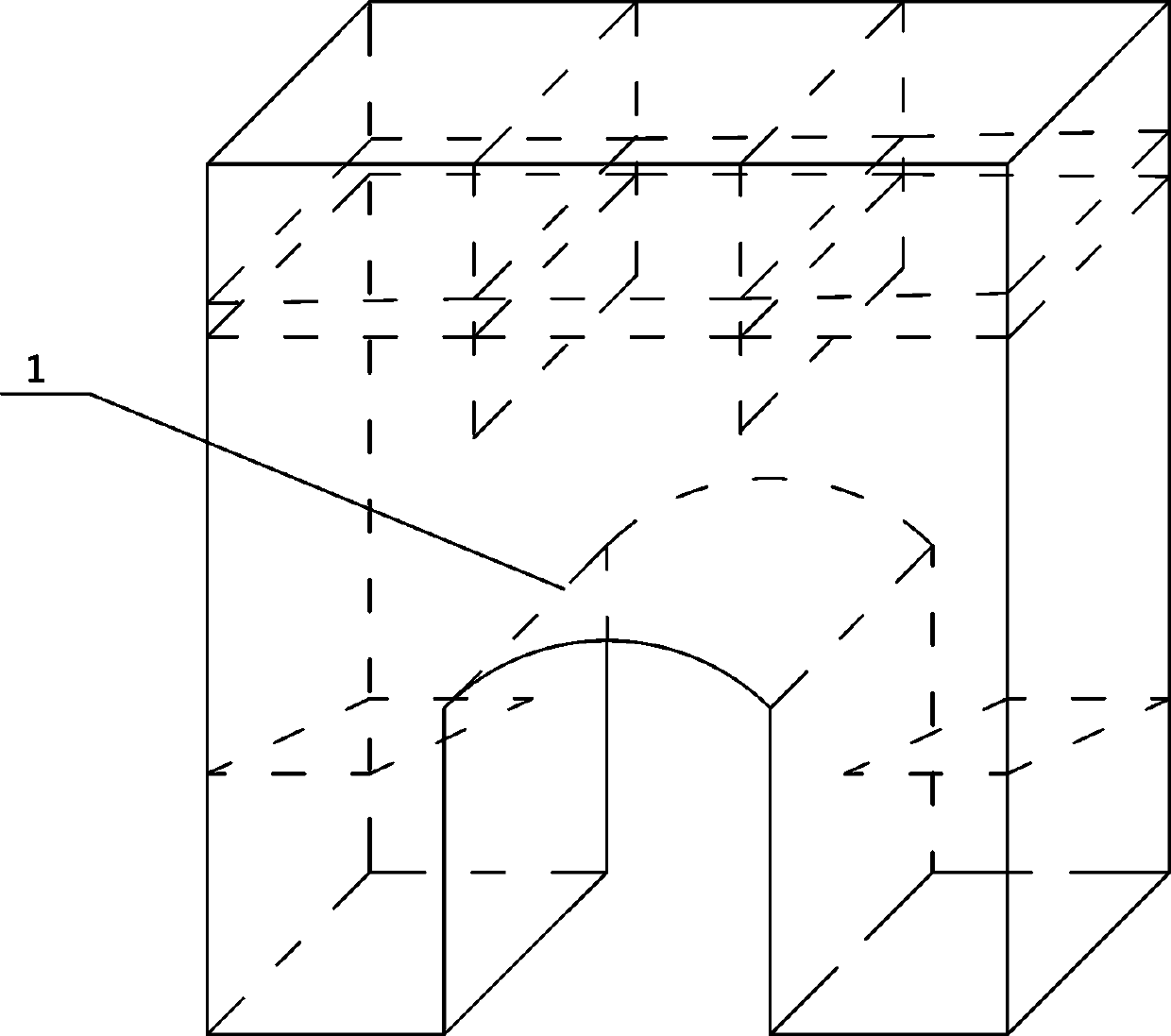

[0040] Such as Figure 1-Figure 4As shown, a device for simulating the forces in different regions of an arched tunnel, including simulating the three-dimensional structure of the tunnel,

[0041] The three-dimensional structure of the simulated tunnel is composed of a hollow arc-shaped tunnel section 1 without a cover and a hollow uncovered linear tunnel section 4 connected to both ends of the arc-shaped tunnel section 1. The highest point of the side wall 2 of the arc-shaped tunnel section 1 is provided with a first pressure relief port 6, and a second pressure relief port 6 is provided on the side wall 2 between the first pressure relief port 6 and a hollow straight tunnel section 4 without a cover. The pressure port 7 simulates the three-dimensional structure of the tunnel filled with a fluid filling 8; the fluid filling 8 on the top opening of the arc-shaped tunnel section 1 is covered with a thin film;

[0042] The top of the three-dimensional structure of the simulated...

Embodiment 2

[0053] A method for simulating stress tests in different regions of an arched tunnel by using the above-mentioned device, the method includes the following steps:

[0054] Step 1: Prefabricate the three-dimensional structure of the simulated tunnel;

[0055] Step 2: Open the first pressure relief port 6 at the highest point of the side wall 2 of the simulated three-dimensional structure of the tunnel, and open the first pressure relief port 6 on the side wall 2 between the first pressure relief port 6 and a hollow straight tunnel section 4 without a cover. Second pressure relief port 7;

[0056] Step 3: Paste the pressure sensor at the corresponding position on the inner wall of the simulated three-dimensional structure of the tunnel;

[0057] Step 4: Weld the strain gauges at the corresponding positions on the inner wall of the three-dimensional structure of the simulated tunnel;

[0058] Step 5: Filling the fluid filling: Fill the fluid filling 8 into the three-dimensional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com