Full-automatic winding machine

A winding machine, fully automatic technology, applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc., can solve the problems of low working efficiency, high labor cost, and low degree of automation of winding machines, and achieve the degree of automation High efficiency, high work efficiency, and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] With the development of science and technology and the increase of labor costs, mechanized production and processing tend to be automated. The winding machine in the prior art needs to manually install the workpiece, unload the coil, and adjust the rollers of the holding mechanism, which cannot meet the needs of automation. The invention provides a fully automatic winding machine capable of automatically installing workpieces, winding workpieces and unloading coils.

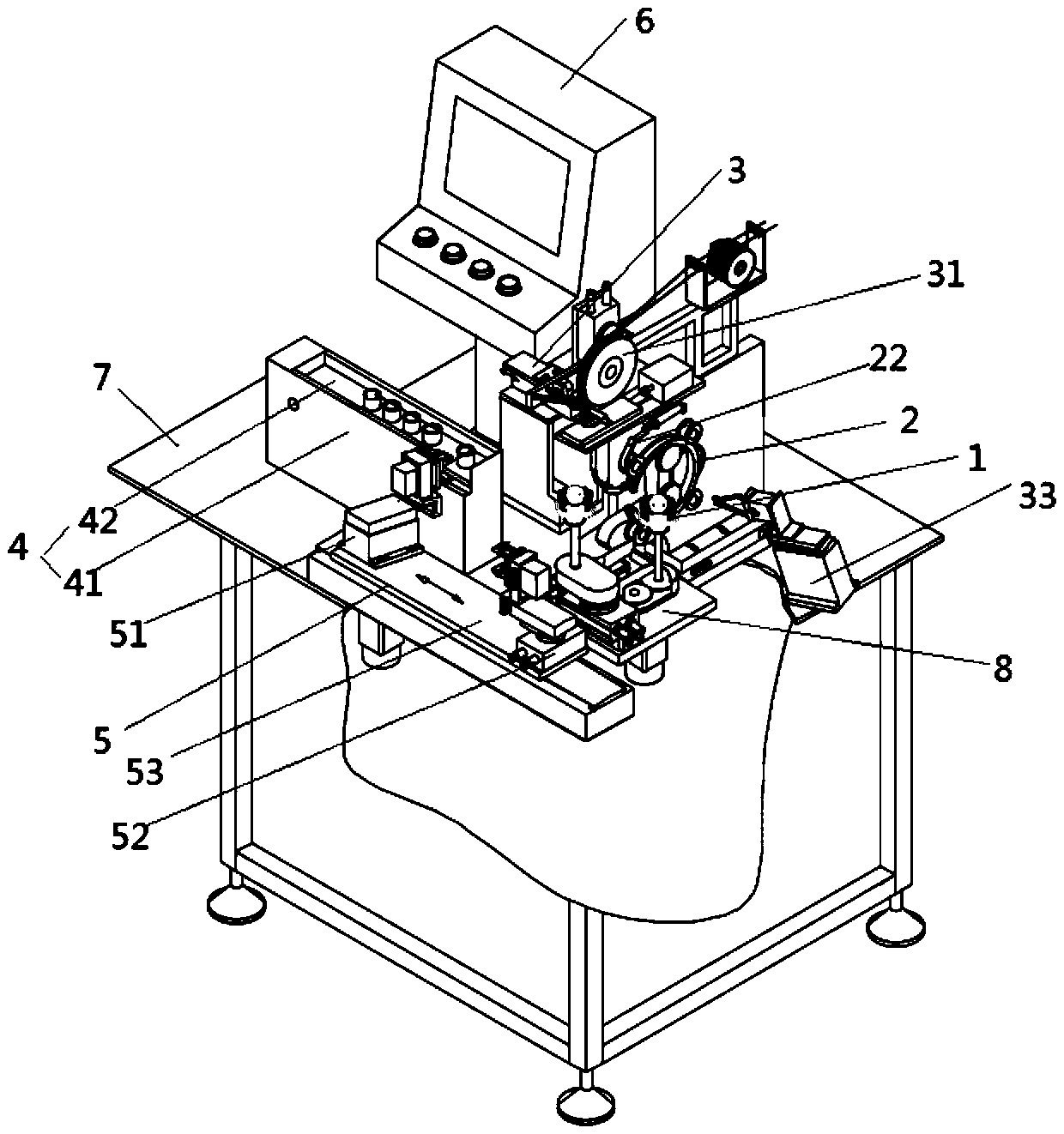

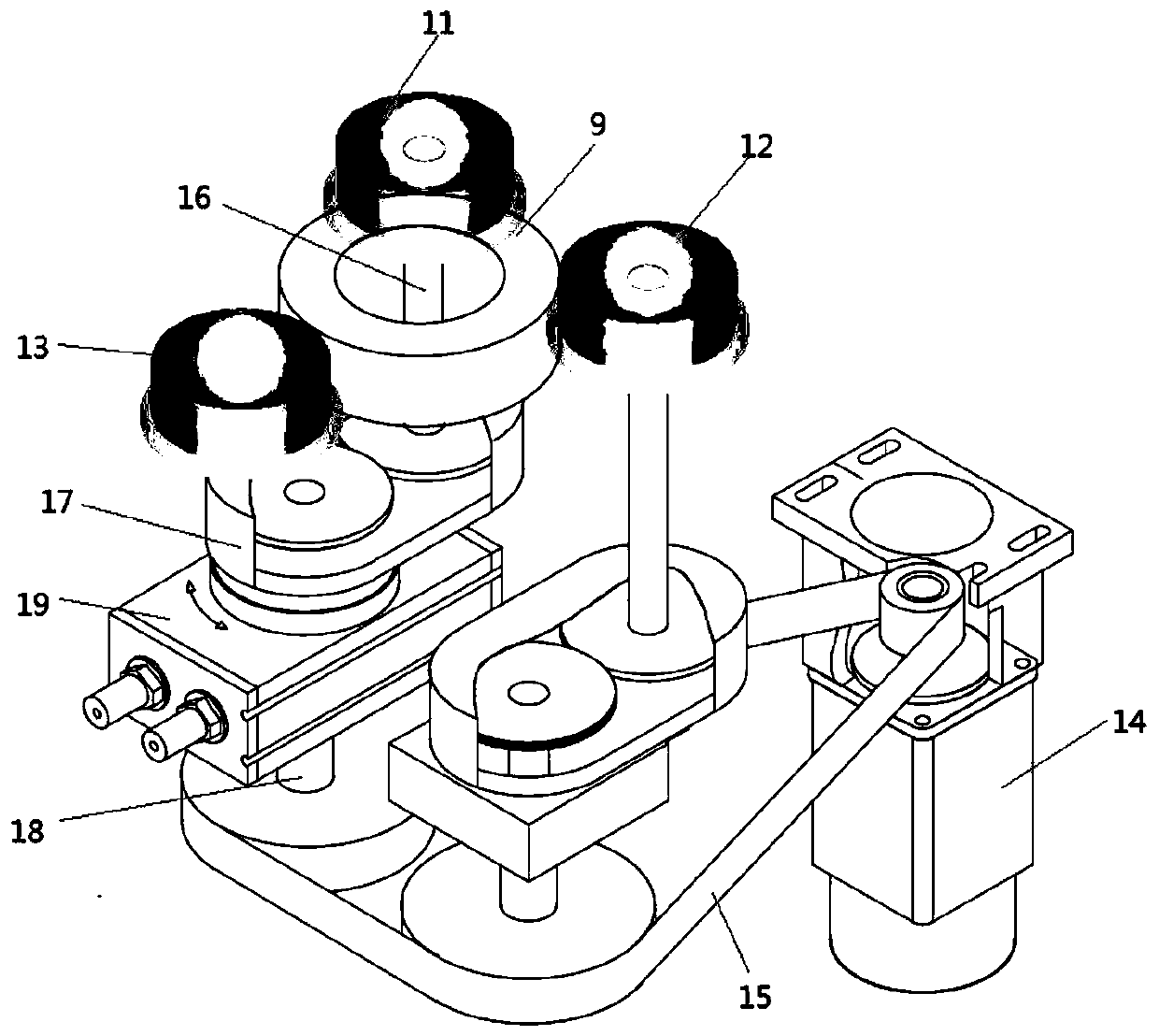

[0051] The fully automatic winding machine includes a support table 7 and a holding mechanism 1 and a loading and unloading mechanism 5 installed on the support table 7. The holding mechanism 1 includes a first rotating roller 11, a second rotating roller 12 and a third rotating roller. Turning roller 13; The first turning roller 11, the second turning roller 12 and the third turning roller 13 form a working position, the first turning roller 11, the second turning roller 12 and the first turning roller Th...

Embodiment 2

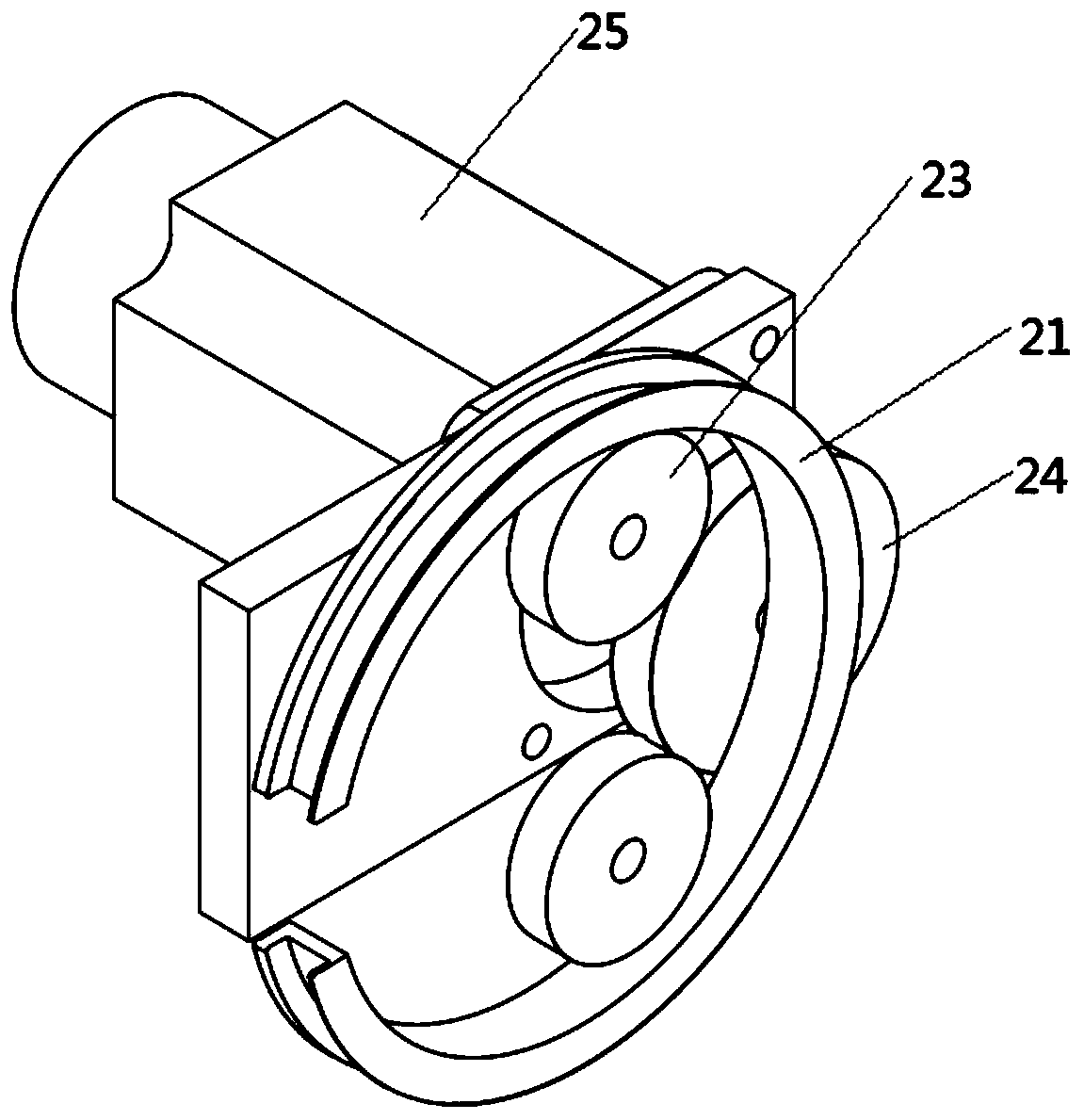

[0080] Such as Figure 7 As shown, as an alternative to embodiment 1, it is a winding machine with tape wrapping function, with the support table 7 described in embodiment 1 and the gripping mechanism 1 installed on the support table 7, The loading and unloading mechanism 5 and the storage mechanism 4 also include: a tape wrapping mechanism, including a tape wrapping ring that wraps the insulating tape around the workpiece at the working position; a tape feeding mechanism, including a leader structure for introducing the insulating tape, And the drawing structure that draws the insulating tape introduced by the leading tape structure into the belt loop, the drawing structure includes an insulating tape clamp for clamping the insulating tape; the dripping mechanism 20 includes a heating Form hot-melt glue, and spray the hot-melt glue on the insulating tape for fixing the heating cylinder.

[0081] The tape leader structure includes a loading reel 37, a pulley 36 that guides th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com