Tensioning belt pulley forming mould

A technology for forming molds and pulleys, applied in the field of tensioning pulley forming molds, can solve the problems of incomplete elimination of pores, poor strength and toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

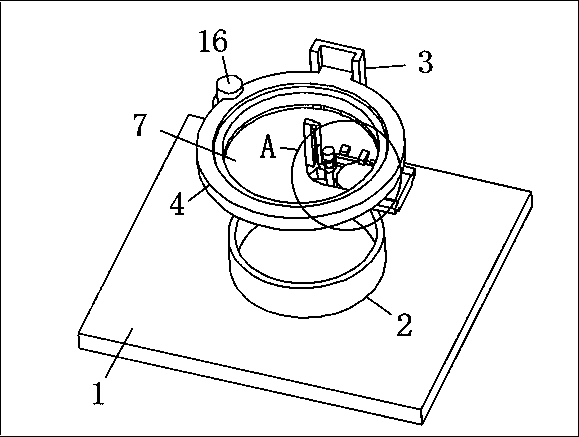

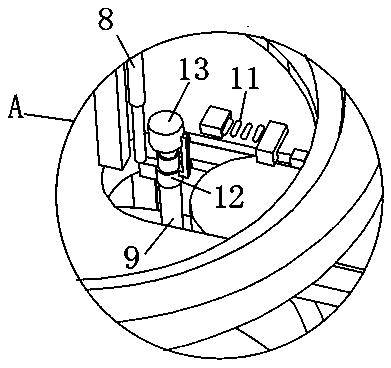

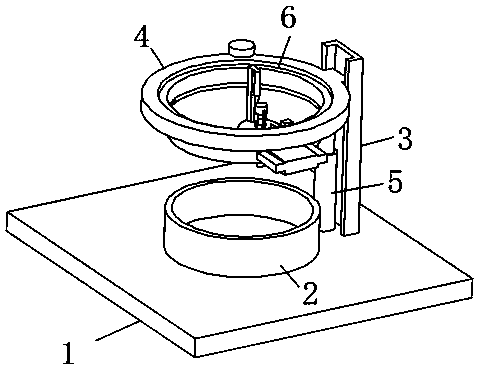

[0018] Attached below Figure 1-4 The specific implementation manner of the present invention will be described in further detail.

[0019] Depend on Figure 1-4 Given, the tensioning pulley molding die of the present invention includes a workbench 1, a lower mold 2 is fixed on the workbench 1, and a column 3 is fixed on the workbench 1, and a mounting frame 4 is slidably installed on the column 3, and the mounting frame 4 is fixedly connected with the workbench 1 through the cylinder 5, a swivel 6 is rotatably installed in the installation frame 4, and an upper mold 7 is detachably connected to the swivel ring 6, and a perforation is provided on the upper mold 7, and the upper end of the upper mold 7 Fixedly be provided with lifting installation frame 8, in the lifting installation frame 8, stirring rod 9 is rotatably installed, and the lower end of the perforation is movably connected with baffle plate 10, and when the baffle plate 10 blocks the perforation, the lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com