Milling cutter

A milling cutter and blade technology, applied in the field of milling cutters, can solve the problems of difficulty in controlling the rotation angle of the blade, waste of the four side walls of the blade, and inability to make full use of the blade, so as to ensure the strength of the blade, improve the cutting effect, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

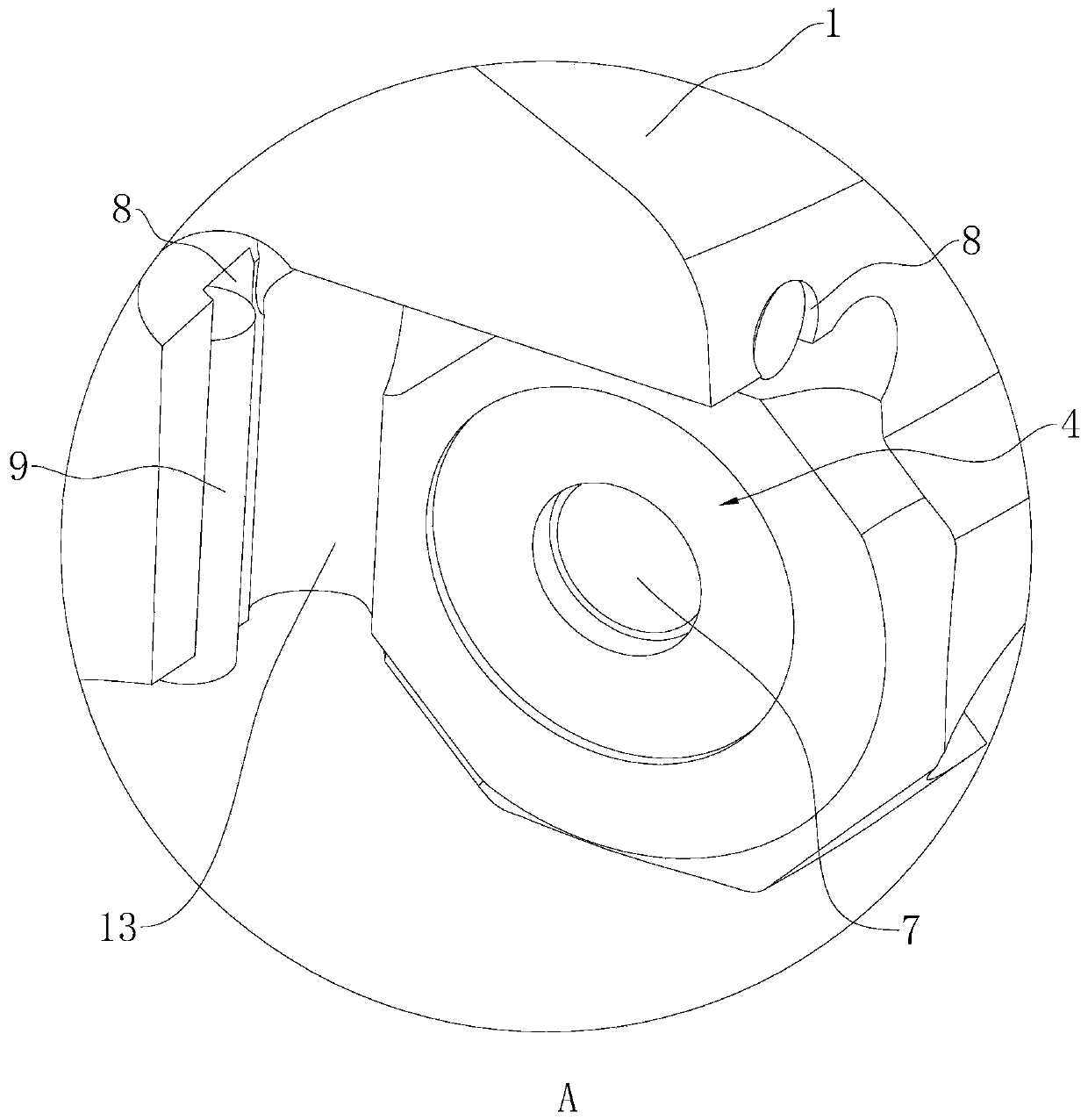

[0044] Embodiment 2: refer to image 3 , the difference from Embodiment 1 is that: the outer wall of one end of the above-mentioned insertion rod 9 in the insertion groove 8 is provided with a section of external thread, and the inner wall of the insertion groove 8 is provided with an internal thread that cooperates with the external thread of the insertion rod 9; A turning slot (not shown in the figure) for inserting and rotating a screwdriver is provided on the end surface of the inserting rod 9 facing outside the inserting slot 8 .

[0045] The implementation principle of this embodiment is: to turn the blade 2, first use a screwdriver to rotate the two insertion rods 9 out of the insertion slot 8, and then use a screwdriver to loosen the locking bolt 5, and then manually drive the blade 2 to rotate , make it change the cutting edge to cut the workpiece, and then thread the inserting rod 9 into the inserting groove 8 to position the angle of the blade 2, and finally drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com