Organic glass recovery equipment

A technology for recycling equipment and plexiglass, applied in the field of plexiglass recycling equipment, can solve the problems of wasting labor, low work efficiency, and inconvenient recycling of plexiglass, and achieve the effects of labor saving, high work efficiency, and power saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

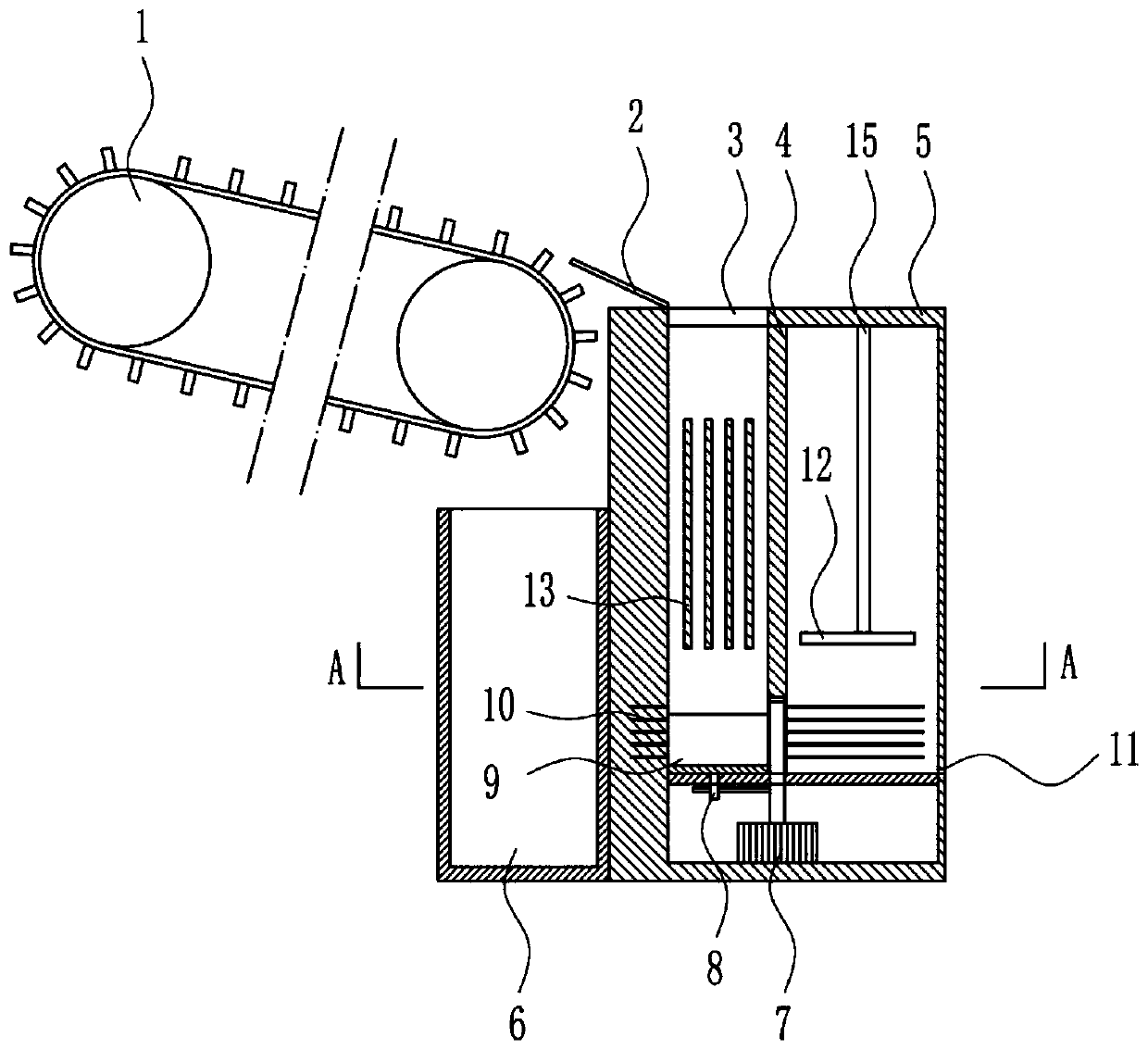

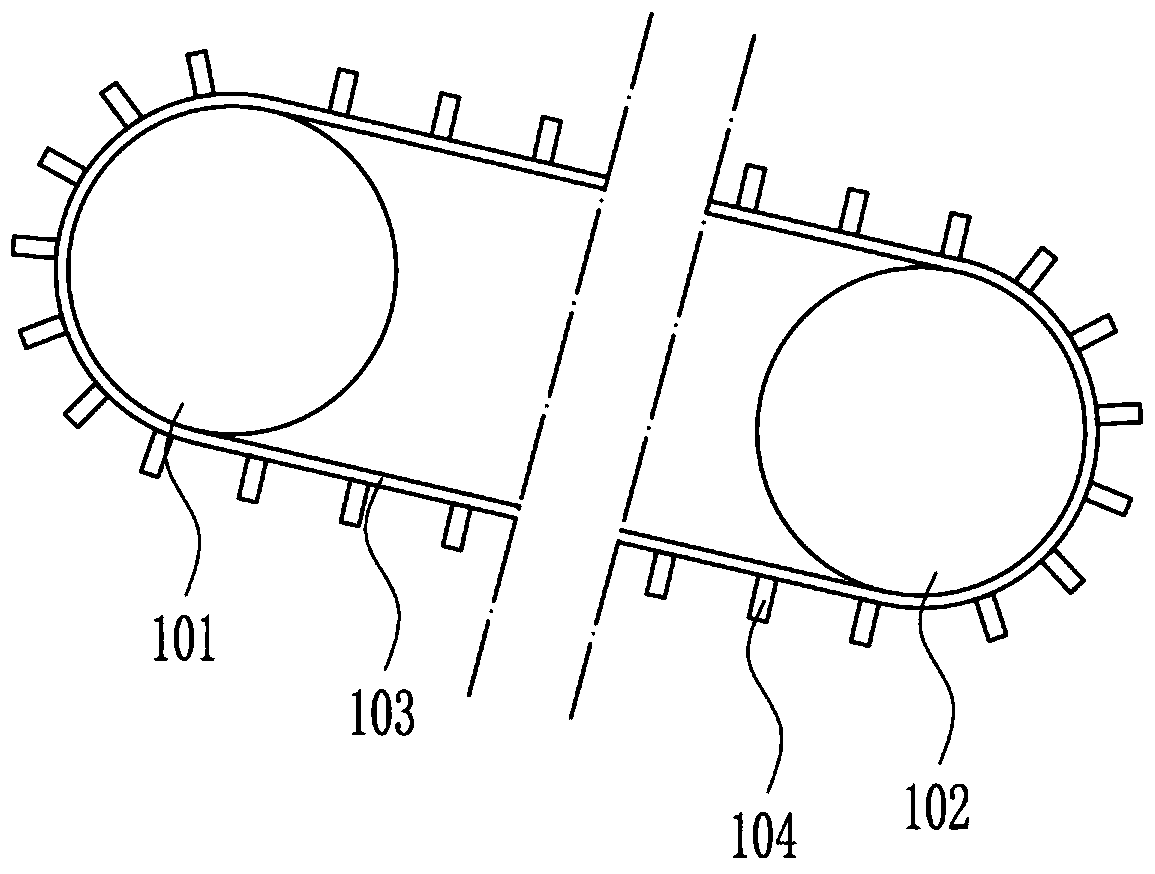

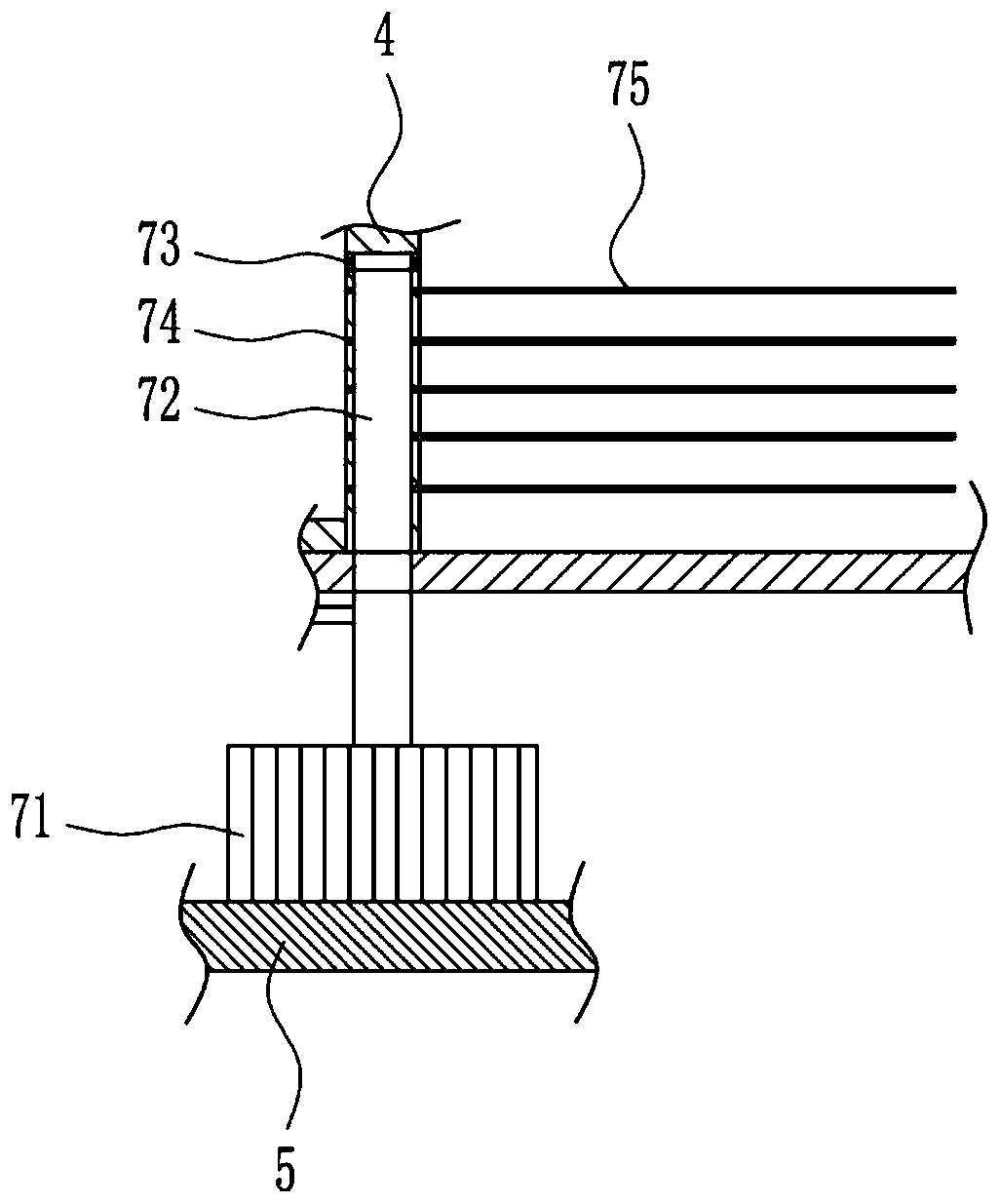

[0032] A kind of plexiglass recycling equipment, such as Figure 1-12 As shown, it includes a conveying mechanism 1, a baffle 2, a partition 4, a processing box 5, a first collecting frame 6, a chopping mechanism 7, a transfer mechanism 8, a third collecting frame 9, a nozzle 12, a strip 13, a lifting Mechanism 14 and water pipe 15; the first collecting frame 6 is fixedly connected to the side of the processing box 5, and the conveying mechanism 1 is fixedly connected obliquely above the first collecting frame 6; Plate 2, baffle plate 2 cooperates with the output end of conveying mechanism 1; On the side near the baffle plate 2, the top of the processing box 5 is provided with a feed port 3; Plate 4, a transfer mechanism 8 is fixedly connected between the two side walls of the processing box 5 below the partition 4; the output end of the transfer mechanism 8 is fixedly connected with a third collection frame 9; the processing box 5 near the third collection frame 9 A pluralit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap