Manufacturing method of bicycle rim wound by carbon fiber prepreg tape

A carbon fiber prepreg and manufacturing method technology, which is applied in the manufacturing field of carbon fiber prepreg tape wound bicycle rims, can solve the problem that the overall structural strength of the finished rim is not high, the dimensional deformation of the finished rim varies greatly, and the overall molding operation is difficult. problems, to achieve the effect of shortening working hours and procedures, speeding up the production process, and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

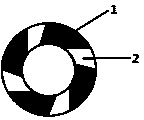

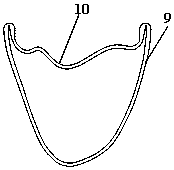

[0027] Specific implementation mode one: as Figure 1-Figure 5 As shown, this embodiment discloses a method for manufacturing a bicycle rim wrapped with carbon fiber prepreg tape. The carbon fiber prepreg tape wound bicycle rim has a two-layer structure, that is, from the inside to the outside, there are mandrel layer and carbon fiber Prepreg tape winding layer, the manufacturing method of described carbon fiber prepreg tape winding bicycle rim comprises:

[0028] Step A: Fill the mandrel 2 (an annular ring body) of thermoplastic material (such as thermoplastic rubber, TPU material or TPR material) with gas (such as air), and the pressure of the gas charged is 0.2Mpa (the amount of gas charged should be It can ensure that the carbon fiber prepreg tape 1 is stably wound on the surface of the mandrel 2), so that the carbon fiber prepreg tape 1 can stably cover the surface of the mandrel 2;

[0029] Step B: Wrap the carbon fiber prepreg tape 1 all over the surface of the mandrel...

specific Embodiment approach 2

[0035] Specific implementation mode two: as figure 1 , image 3 As shown, this embodiment is a further description of specific embodiment 1. In step A, the outer circumference of the section of the mandrel 2 perpendicular to its axis should be the same as the inner circumference of the finished bicycle rim 9. Same length (guarantees no wrinkling when squeezed and cured).

specific Embodiment approach 3

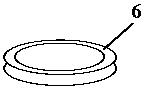

[0036] Specific implementation mode three: as figure 2 , Figure 4 As shown, this embodiment is a further description of specific embodiment 1. In step C, the rim mold 6 is made of metal material, and the rim mold 6 includes four equally divided arc rods 7, eight Nut 11 and four screw rods 5, each two ends of the inner circular arc surface of each described arc rod 10 are respectively welded with a nut 11, and described four equally divided arc rods 11 form a circle, each adjacent Two nuts 11 are internally screwed with a screw rod 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com