Steel scrap scale plate conveyor scale plate

A technology of conveyors and scales, which is applied in the field of scrap steel scale conveyor scales, can solve problems such as increased use costs, increased equipment power consumption, and scale deformation, so as to prolong the service life, strengthen the bearing capacity, and reduce the degree of deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

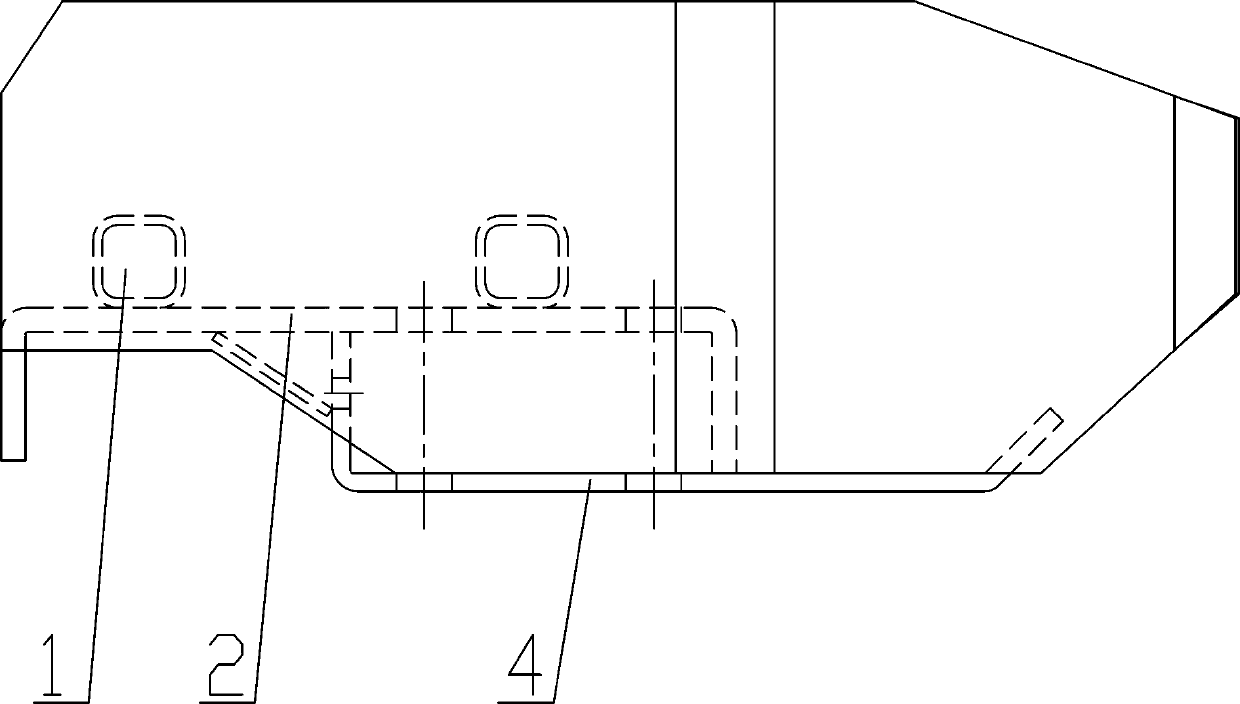

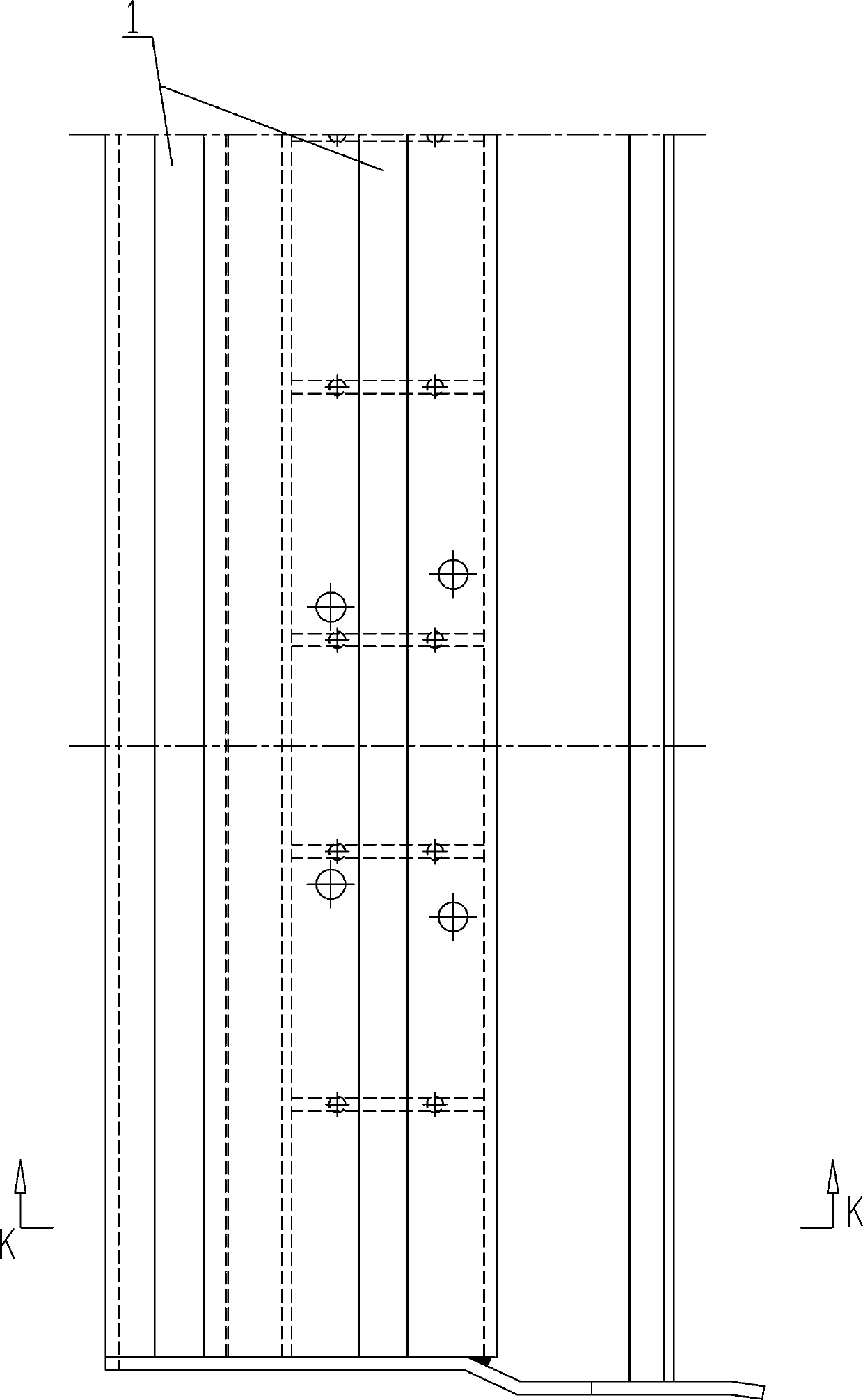

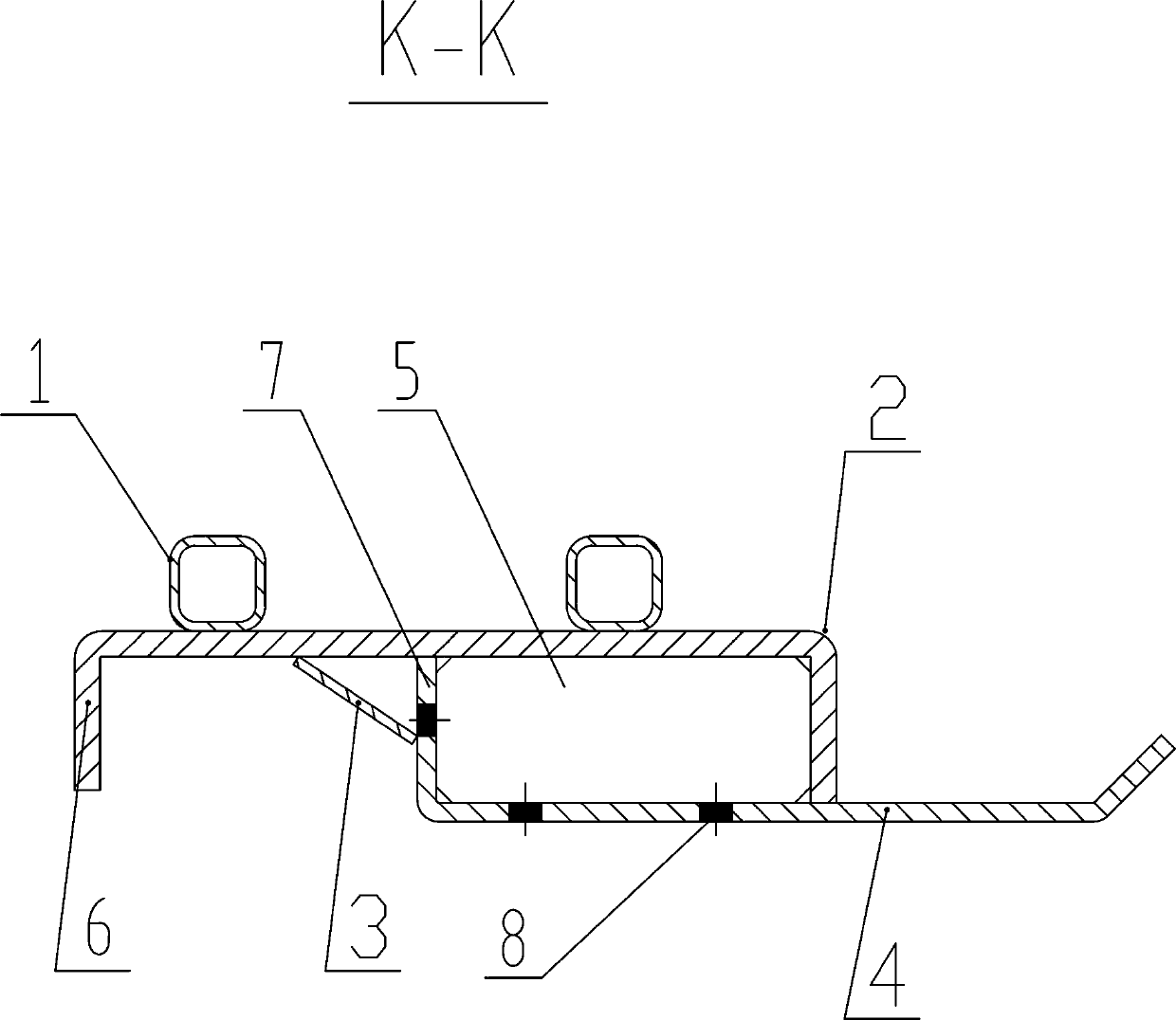

[0017] Such as Figure 1-4 As shown, a scrap steel scale plate conveyor scale plate includes a square tube 1, an upper channel plate 2 and a lower channel plate 4, wherein the square tube is divided into two and welded on the upper channel plate 2 horizontally superior. In the process of steel scrap falling or conveying, because the square pipe is a hollow structure, it can be cushioned to a certain extent, and the bearing capacity is stronger. In addition, it is buckled and welded with the upper and lower grooved plates and the ribs are arranged according to the spacing, so that the overall load capacity The resistance is strengthened, which makes the impact resistance of the scale stronger and reduces the deformation of the scale. Both ends of the upper grooved plate 2 are bent downwards to form a first folded edge 6, the first folded edges 6 at both ends are perpendicular to the main body of the upper grooved plate 2 and the first folded edge 6 on the left side is larger t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com