Fabricated precast steel fiber concrete pavement

A steel fiber reinforced concrete and fiber reinforced concrete technology, which is applied to pavements, roads, roads and other directions paved with prefabricated blocks, can solve the problems of self-heavy prefabricated panels, unreliable panel connection and low strength, etc., saving labor and connecting The method is simple and reliable, and the effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

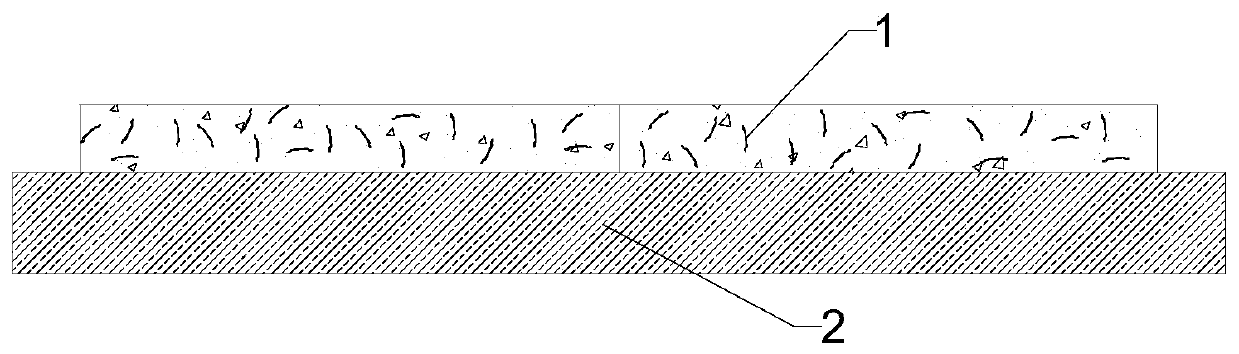

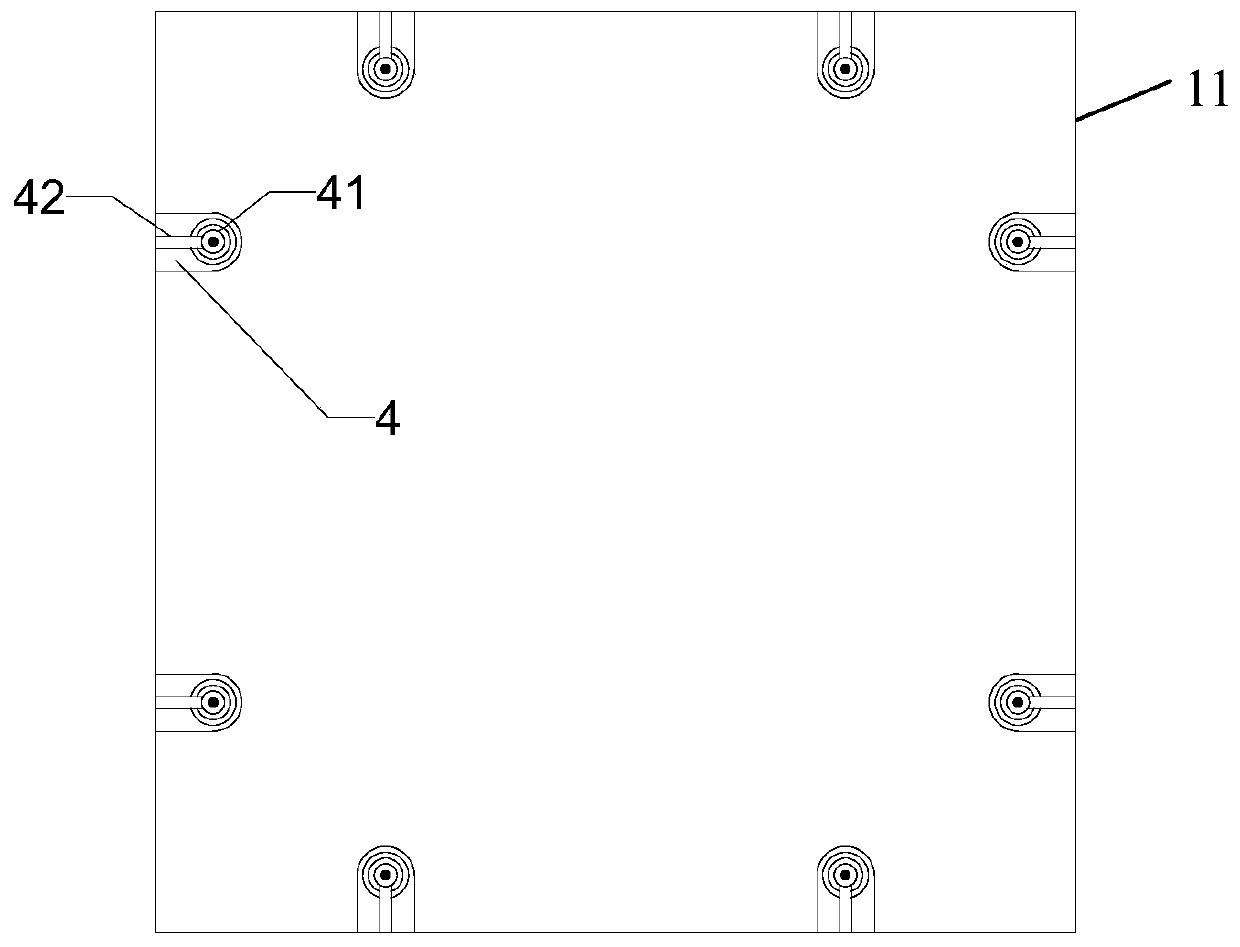

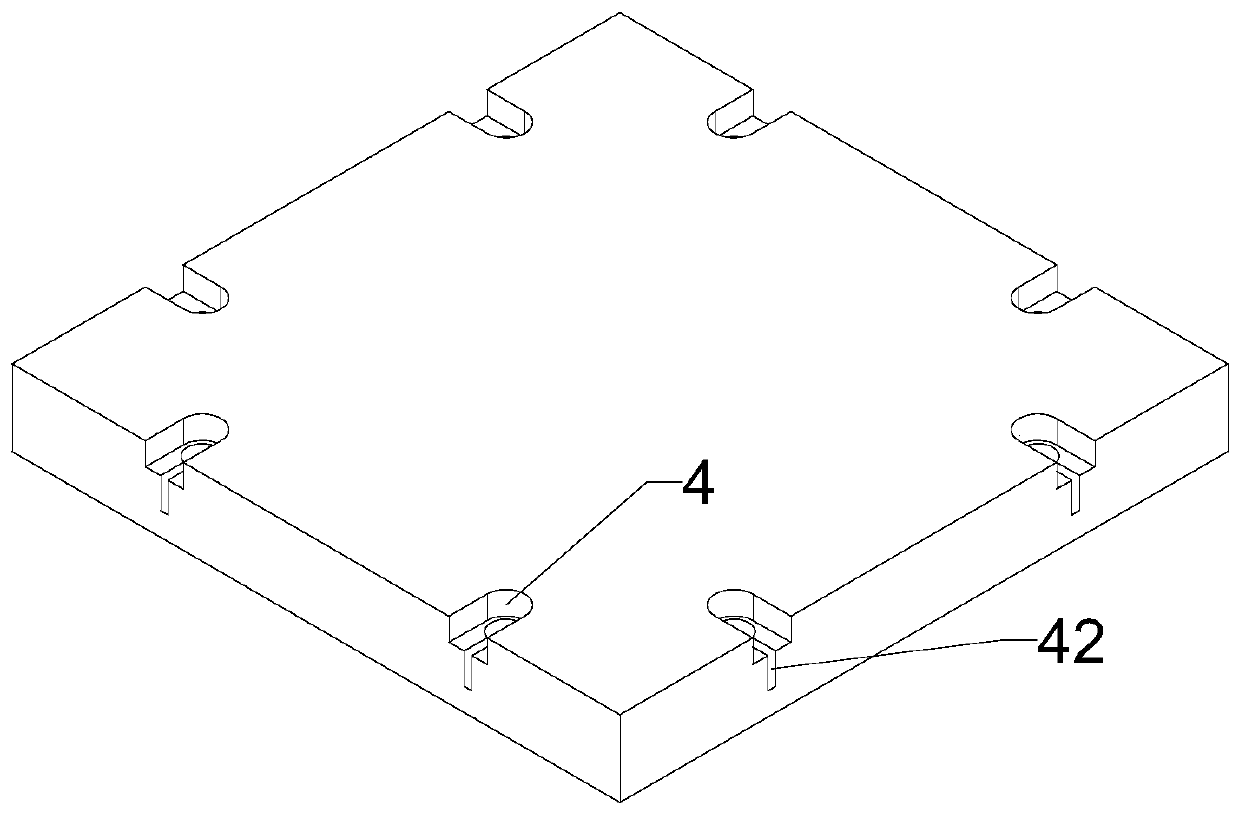

[0015] like Figure 1~2 As shown, an assembled prefabricated steel fiber concrete pavement includes a plurality of steel fiber concrete poured prefabricated panels 1 laid on the compacted pavement, and a lime-soil cushion 2 is arranged between the prefabricated panels 1 and the compacted pavement; the prefabricated panels 1 includes a plurality of rectangular unit prefabricated panels 11, and a plurality of notches 4 are arranged on the edge of the unit prefabricated panels 11; the circular holes set in the notches 4 penetrate the prefabricated panels 1; the connecting piece 3 is installed on two adjacent prefabricated units In the notch 4 of the panel 11; the bolt 5 passes through the circular hole on the connector 3 and the notch 4 and is fixed with the lime soil cushion. The unit prefabricated panel 11 is generally a square or rectangular structure.

[0016] The notch 4 is a U-shaped notch, and the edge notches 4 of adjacent unit prefabricated panels 11 correspond one by o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com