High water head water pump turbine rotating wheel double sealing pressure decreasing structure

A water pump turbine and high water head technology, which is applied in hydroelectric power generation, mechanical equipment, engine components, etc., can solve the problems of safe and stable operation of theoretical pressure, high pressure and luffing units, and achieve the reduction of alternating stress and the amplitude of water pressure fluctuations , the effect of reducing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

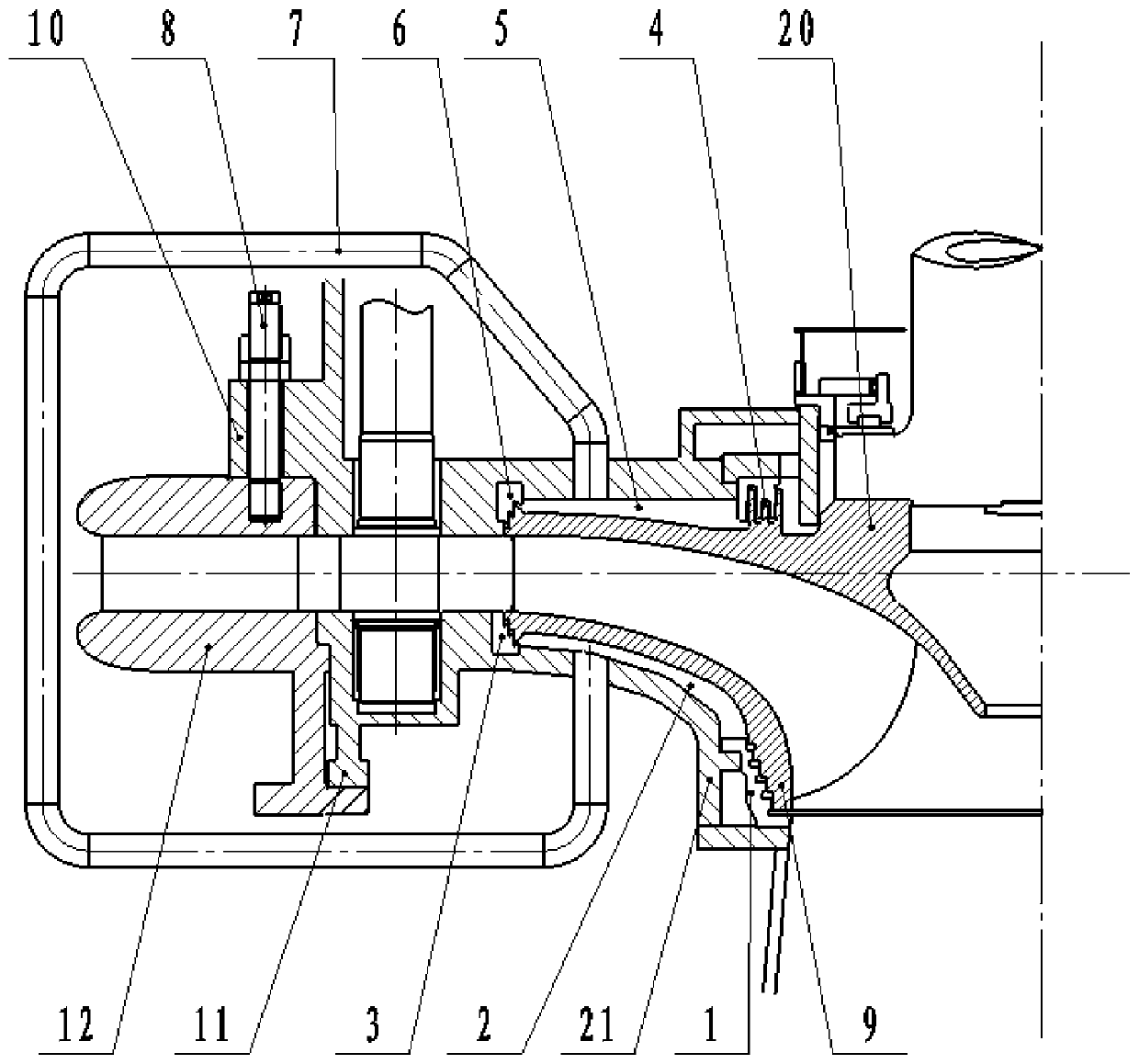

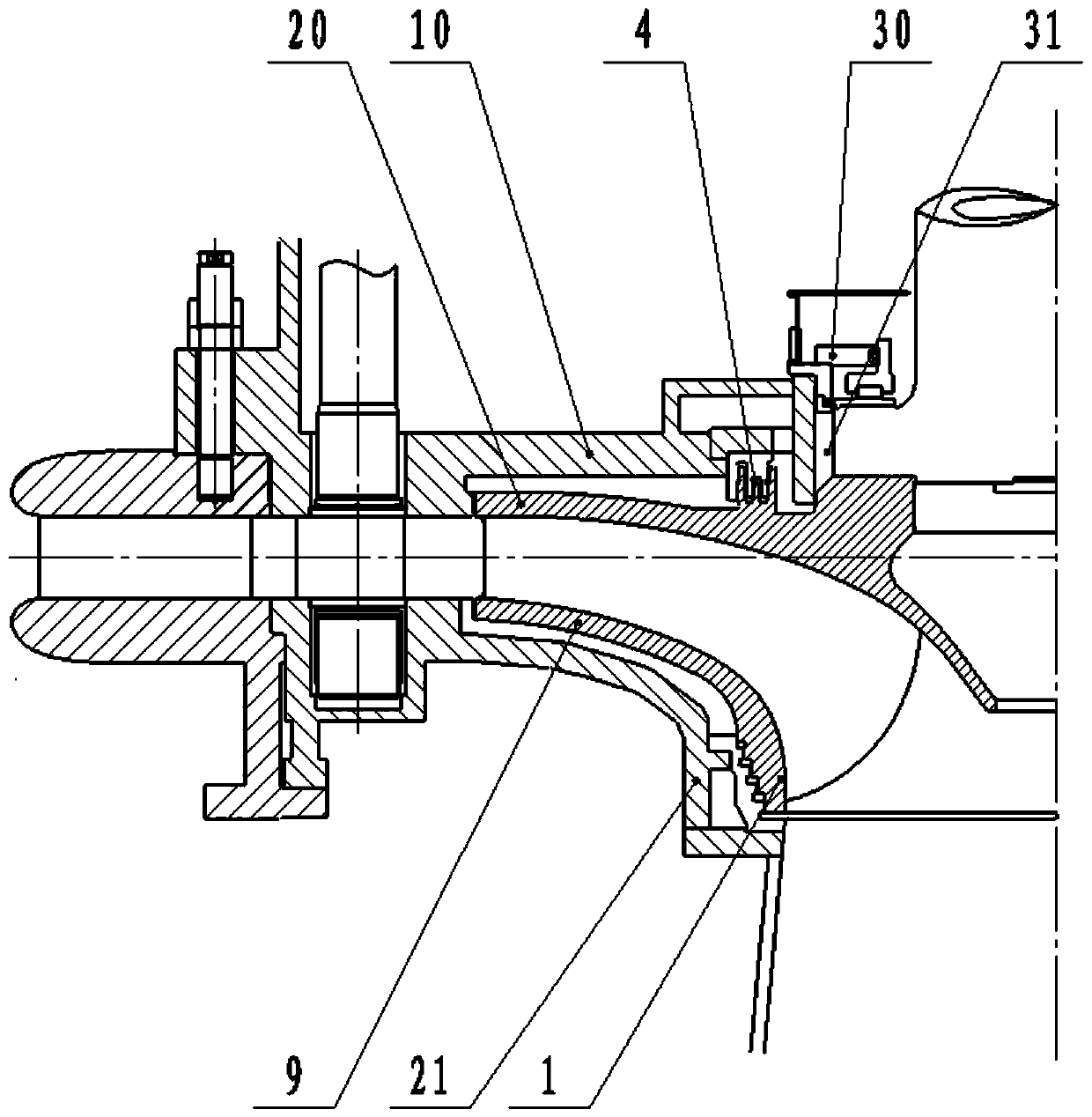

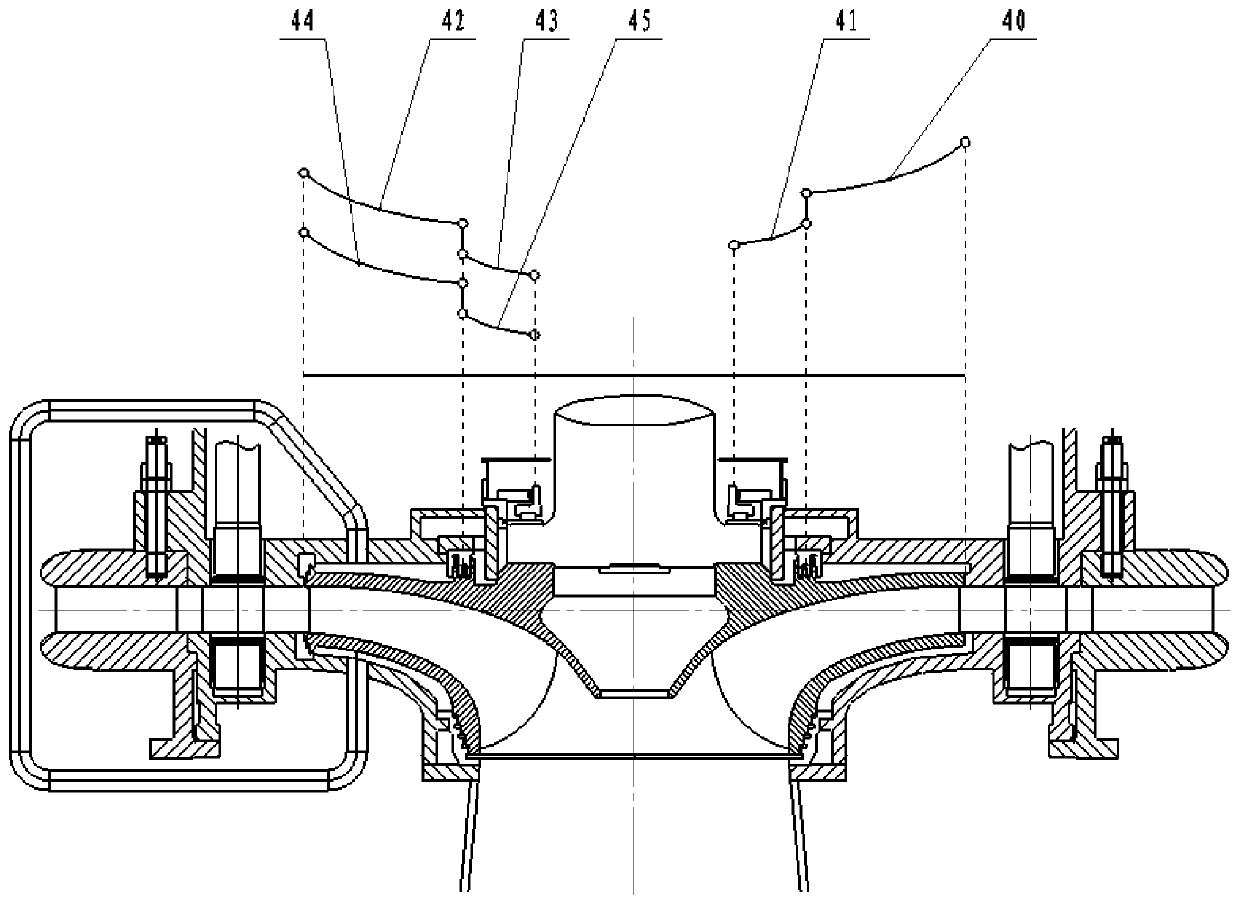

[0020] Specific implementation methods: such as Figure 1-3 As shown, two sets of anti-leakage ring sealing devices 6 and 3 are respectively arranged between the upper crown 20 and the top cover 10 of the runner and between the lower ring 9 and the base ring 21, that is, the upper crown outer diameter is set at the radial maximum diameter of the upper crown 20. The anti-leakage ring 6, the outer anti-leakage ring 3 of the lower ring is set at the radial maximum diameter of the lower ring 9, the outer anti-leakage ring 6 of the upper crown and the outer anti-leakage ring 3 of the lower ring have equal damping, and the lower ring 9 on the low pressure side of the runner is the smallest The inner leak stop ring 1 of the lower ring is set at the diameter, and the damping of the inner leak stop ring 1 of the lower ring is smaller than the damping of the outer leak stop ring 3 of the lower ring. The inner stop ring 4 of the upper crown, the outer stop ring 6 of the upper crown and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com