Micro air compressor

An air compressor, miniature technology, applied in the direction of mechanical equipment, machine/engine, liquid variable capacity machinery, etc., can solve the problems of small volume change of compression chamber, high output pressure, output flow and low pressure, etc., to achieve The effect of large volume power and strong gas delivery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

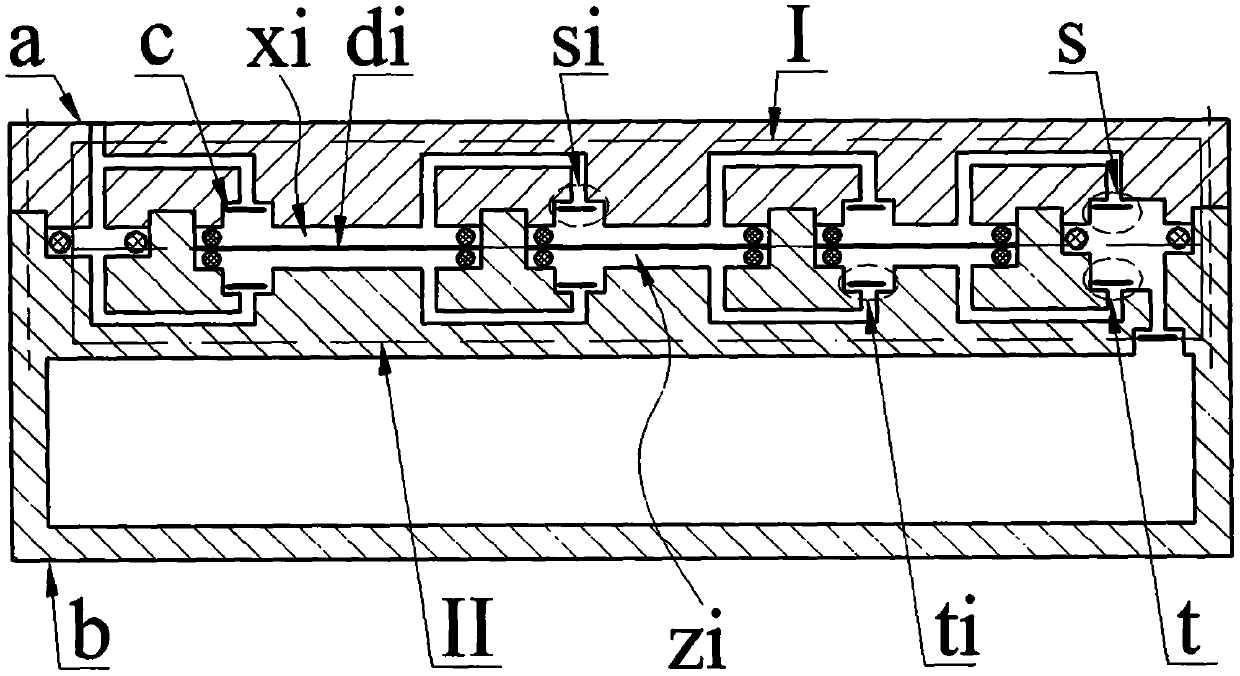

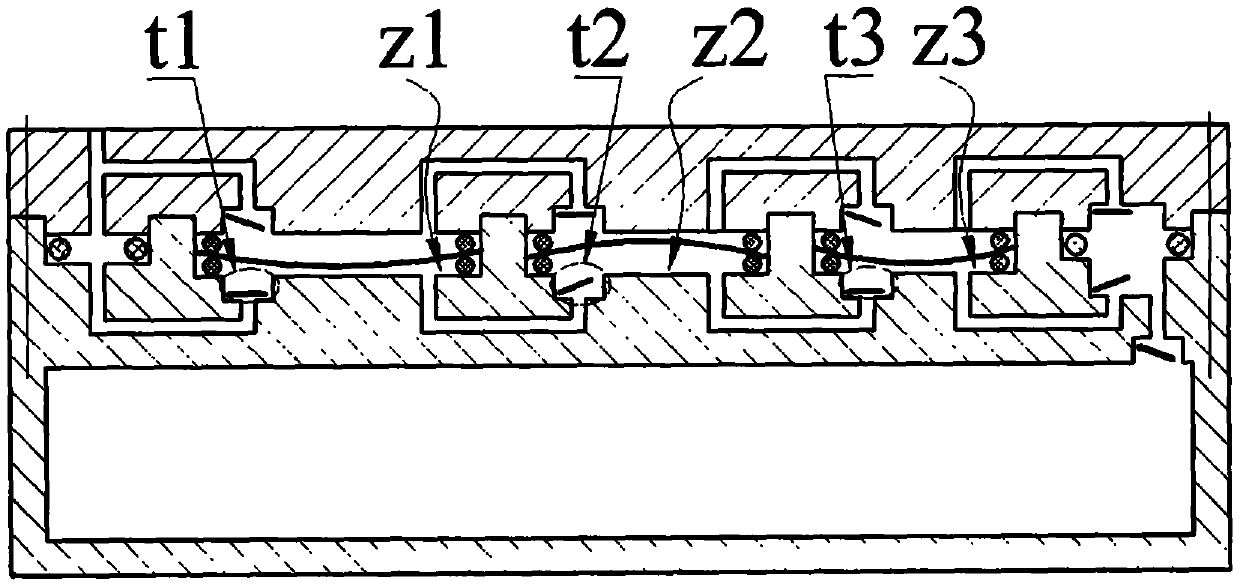

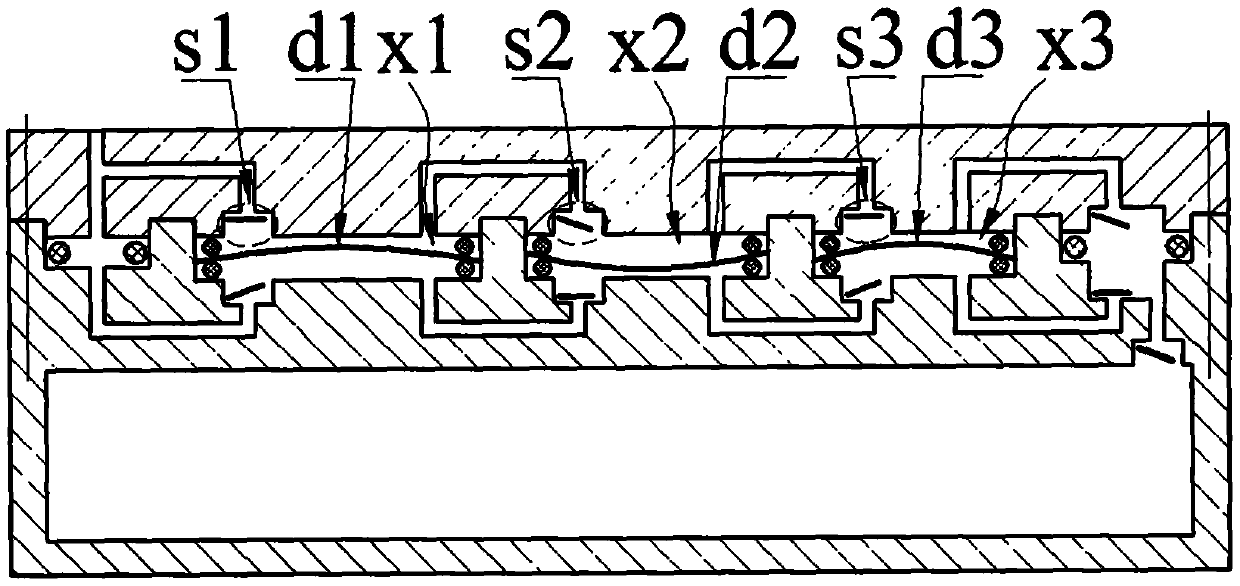

[0016] A miniature air compressor of the present invention is composed of an upper cover a, a box body b, a one-way valve c and a driver di. The upper cover a is installed on the box body b via screws. The bottom of the upper cover a is provided with a left boss a1, a right boss a2 and at least two body platforms a3i with different diameters. The diameters of the body platforms a3i from left to right are Decrease in turn, the left boss a1 is provided with an upper inlet a4, the right boss a2 is provided with an upper outlet a5, and the body platform a3i is provided with an upper inlet a6 and an upper outlet a7; the leftmost body platform a3i The upper inlet a6 is connected with the upper inlet a4, the upper outlet a7 of the rightmost body platform a3i is connected with the upper outlet a5, and the upper inlet a6 and the upper outlet a7 of the other two adjacent body platforms a3i are connected with each other ; The upper inlet cavity a6 and the upper outlet cavity a5 of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com