Reducing two-way pipe joint

A technology of variable diameter interface and through pipe, which is applied in the direction of pipe/pipe joint/pipe fitting, passage element, sealing surface connection, etc. It can solve the problems of loose fixation, poor sealing effect of pipes and joints, etc., to prevent the pipe from detaching from the joint, The effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

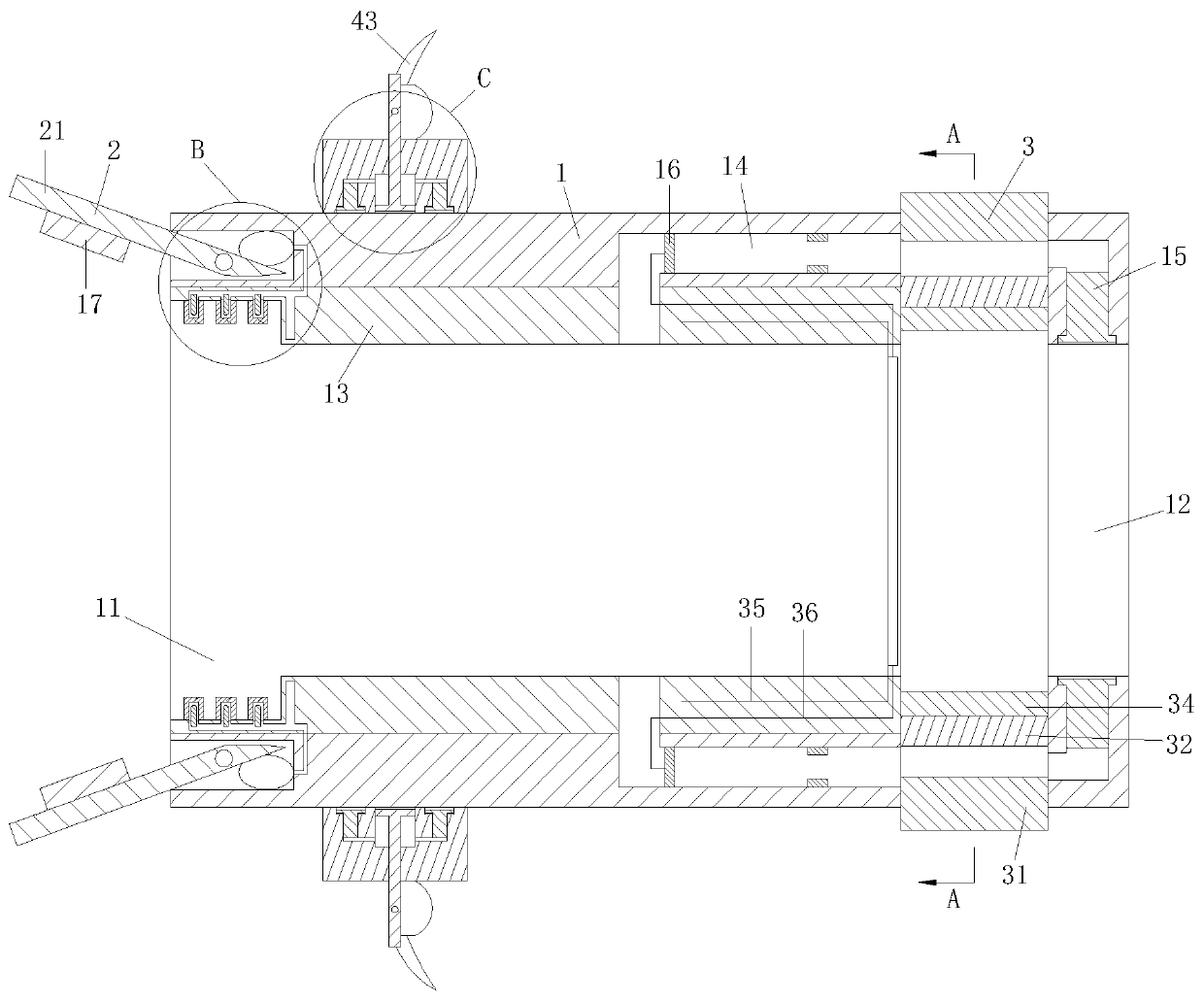

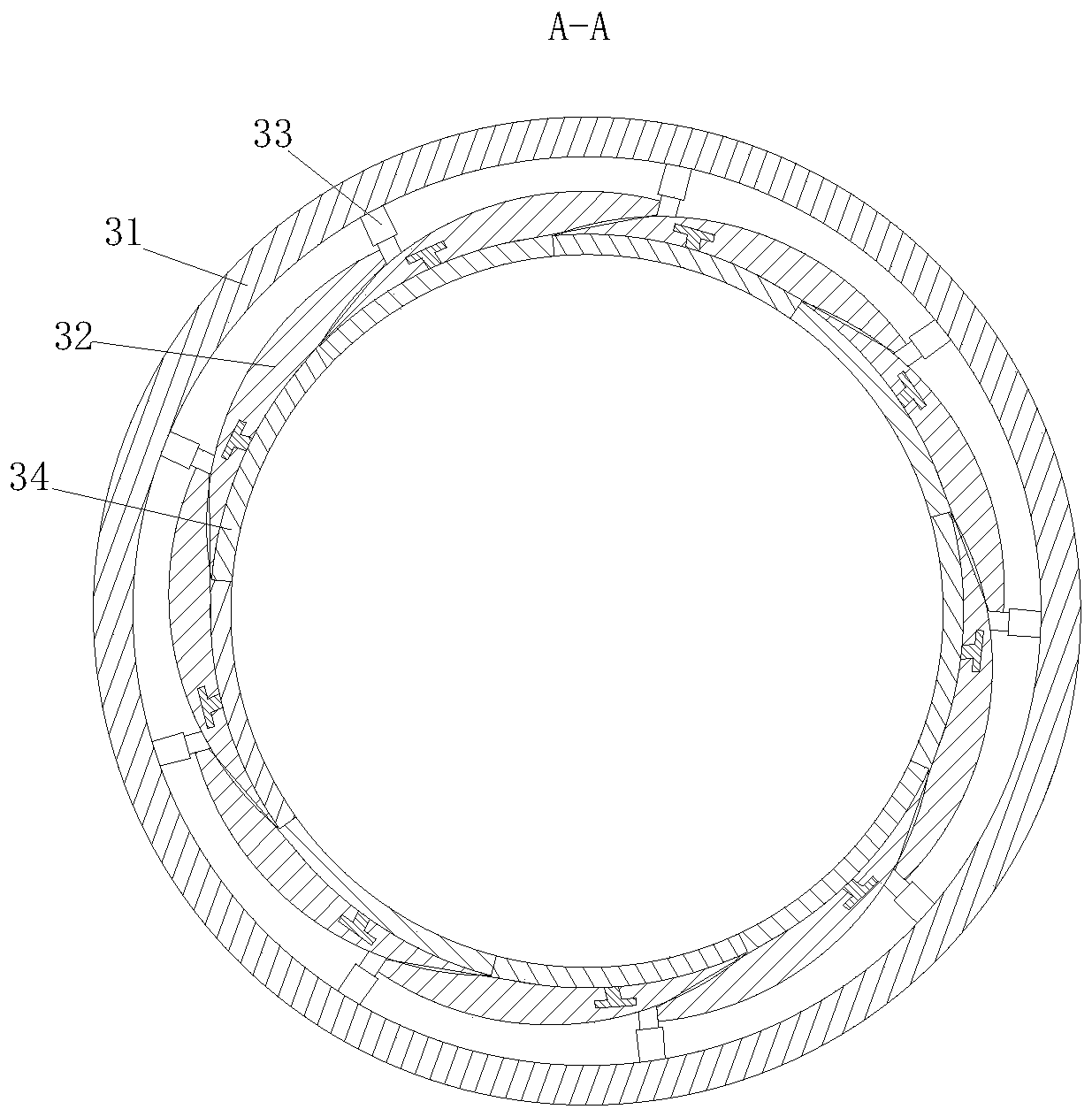

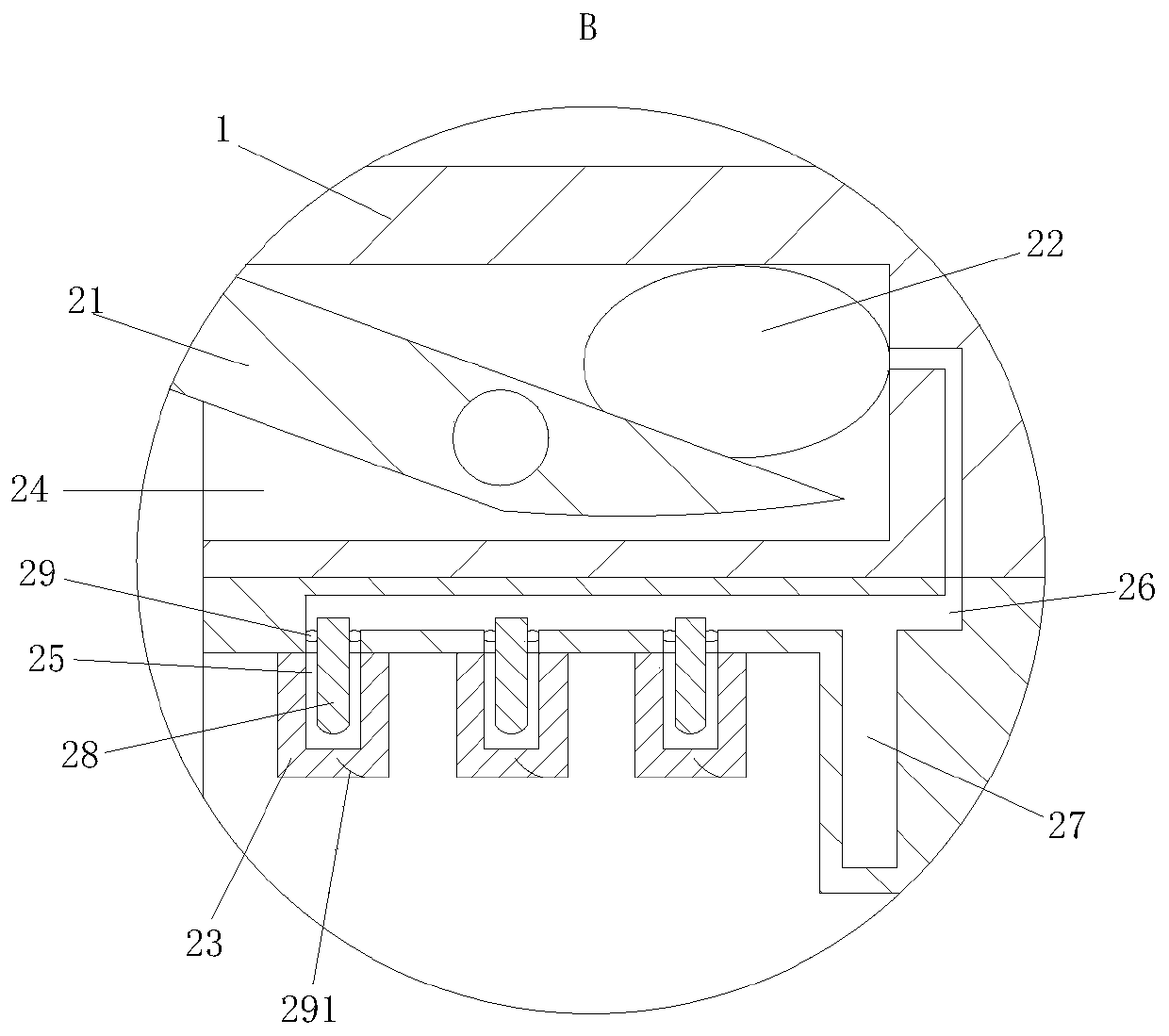

[0022] As an embodiment of the present invention, the reducing unit 3 includes a swivel 31, a reducing plate 32 and a telescopic rod 33; the surface of the pipe body 1 is provided with a circular chute; the swivel 31 slides In the chute, and the sidewalls on both sides of the chute are provided with limit chute, both sides of the swivel 31 are provided with limit blocks, and the limit blocks slide in the limit chute to ensure that the swivel 31 can rotate At the same time, the strength of the pipe body 1 is improved; the diameter-reducing plate 32 is fixedly connected with the expansion rod 33 uniformly arranged in the swivel 31; The arc-shaped design of the plate 32 ensures that the sides of the variable-diameter plates 32 away from the swivel 31 form a circle after contacting each other, and the center of the circle is at the same position as the center of the swivel 31; the variable-diameter plates 32 are slidably connected to each other, And the side walls on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com