A circuit board rapid disassembly equipment

A circuit board, fast technology, applied in the direction of welding equipment, metal processing equipment, manufacturing tools, etc., to achieve fast disassembly, high disassembly efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

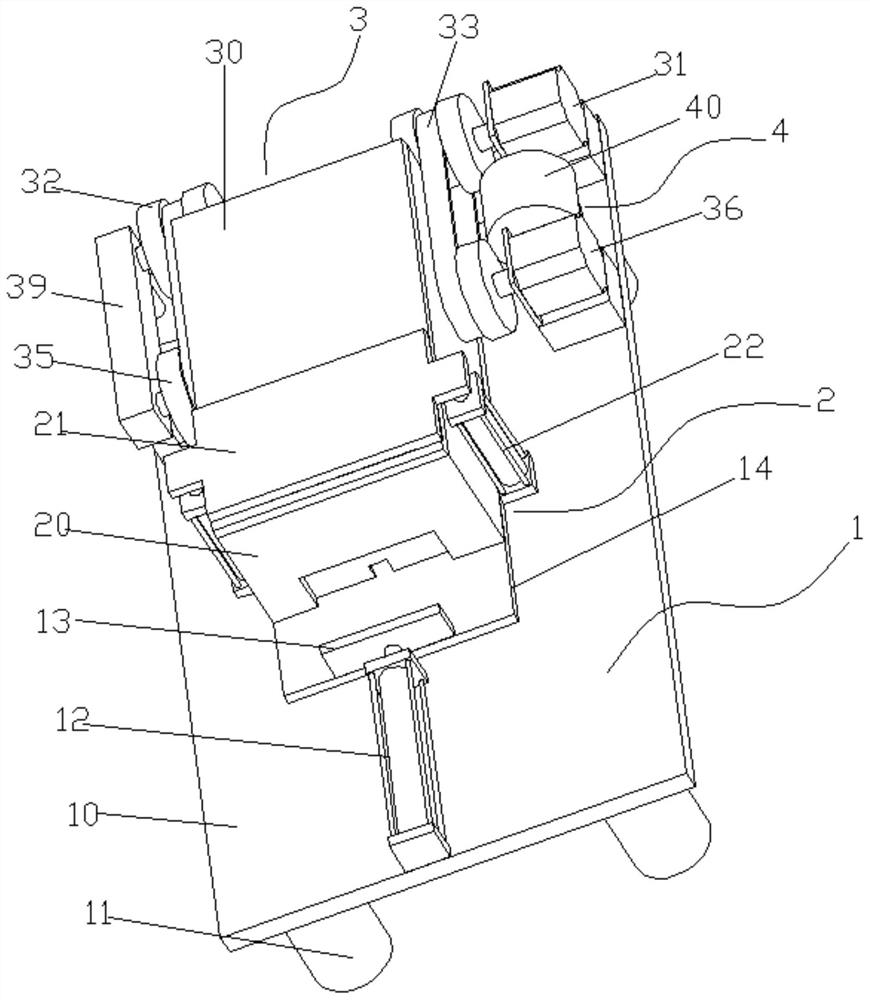

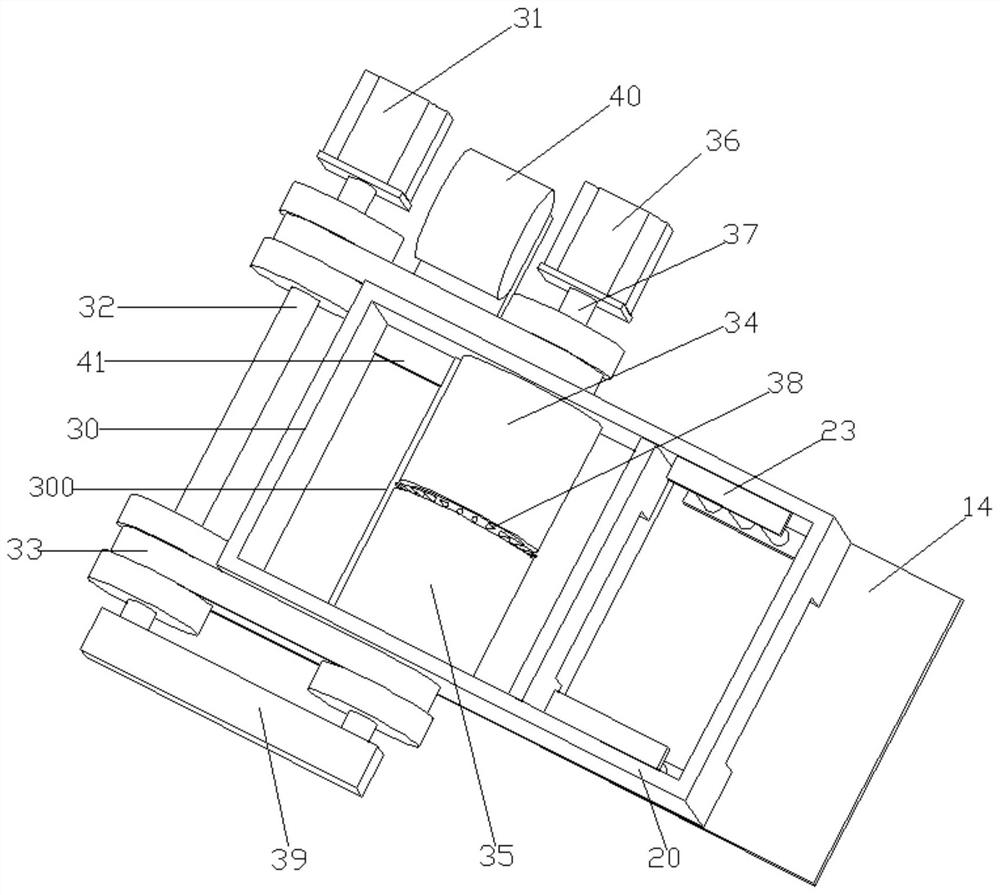

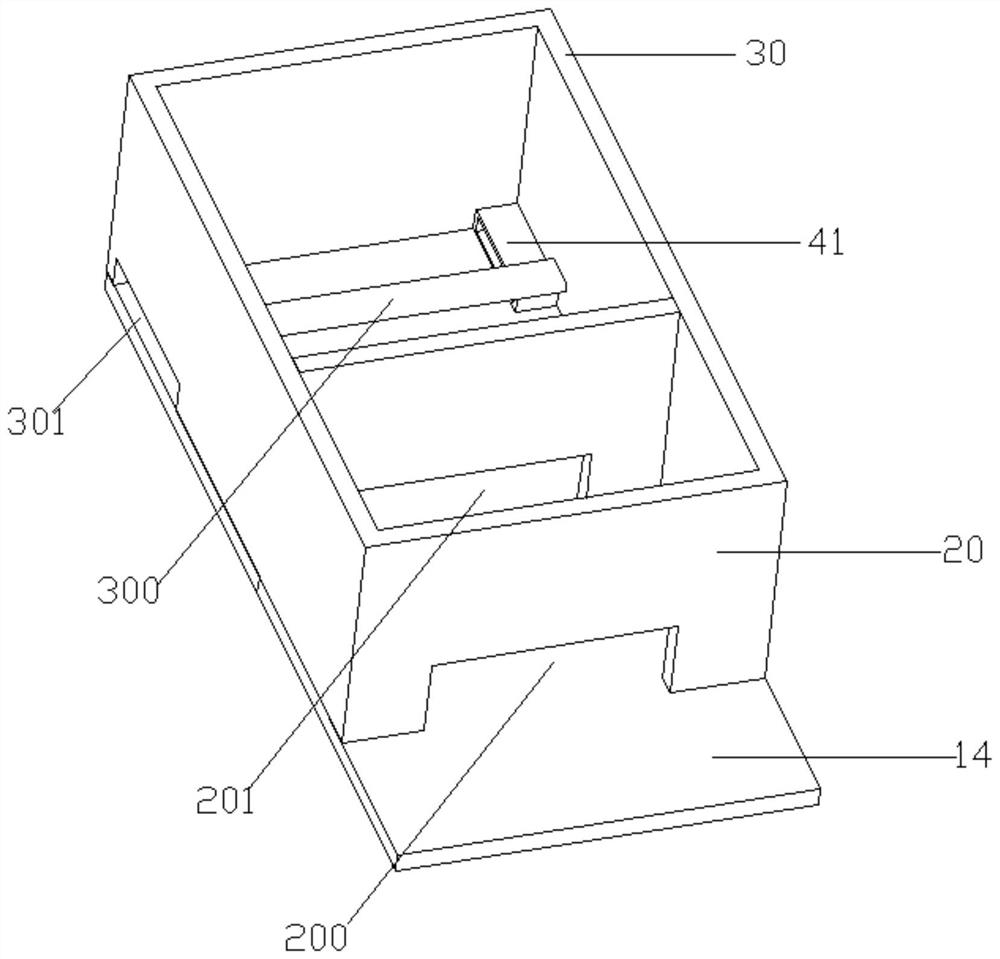

[0031] Such as Figure 1 to Figure 9 As shown, a circuit board rapid disassembly equipment includes a base assembly 1, a heating mechanism 2, a disassembly mechanism 3 and a sorting mechanism 4. The base assembly 1 includes a base 10, a push cylinder 12, and a push plate 13 And the heat shield 14, the push cylinder 12 and the heat shield 14 are fixedly connected on the base 10, the push plate 13 is connected to the output shaft of the push cylinder 12 and the push plate 13 is slidably connected with the heat shield 14;

[0032] The heating mechanism 2 includes a heating box 20, a lifting plate 21, a lifting cylinder group 22, a heater 23 and a lifting door 24. The heating box 20 is fixedly connected to the heat insulation board 14, and the heater 23 is located Inside the box body 20 and fixedly connected on the side wall of the heating box body 20, the lifting cylinder group 22 includes two lifting cylinders and is symmetrically installed on the base 10, and the two lifting cy...

Embodiment 2

[0036] Such as Figure 1 to Figure 9 As shown, a circuit board rapid disassembly equipment includes a base assembly 1, a heating mechanism 2, a disassembly mechanism 3 and a sorting mechanism 4. The base assembly 1 includes a base 10, a push cylinder 12, and a push plate 13 And the heat shield 14, the push cylinder 12 and the heat shield 14 are fixedly connected on the base 10, the push plate 13 is connected to the output shaft of the push cylinder 12 and the push plate 13 is slidably connected with the heat shield 14;

[0037] The heating mechanism 2 includes a heating box 20, a lifting plate 21, a lifting cylinder group 22, a heater 23 and a lifting door 24. The heating box 20 is fixedly connected to the heat insulation board 14, and the heater 23 is located Inside the box body 20 and fixedly connected on the side wall of the heating box body 20, the lifting cylinder group 22 includes two lifting cylinders and is symmetrically installed on the base 10, and the two lifting cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com