Warning device for glass tape cracks

A technology of alarm device and glass ribbon, applied in the direction of alarm, glass manufacturing equipment, glass transportation equipment, etc., can solve the problem of easy cracking and fracturing of glass, avoid production loss and equipment failure, solve process confusion, pull fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the present invention clearer, a glass ribbon crack alarm device of the present invention will be further described below with reference to the accompanying drawings. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

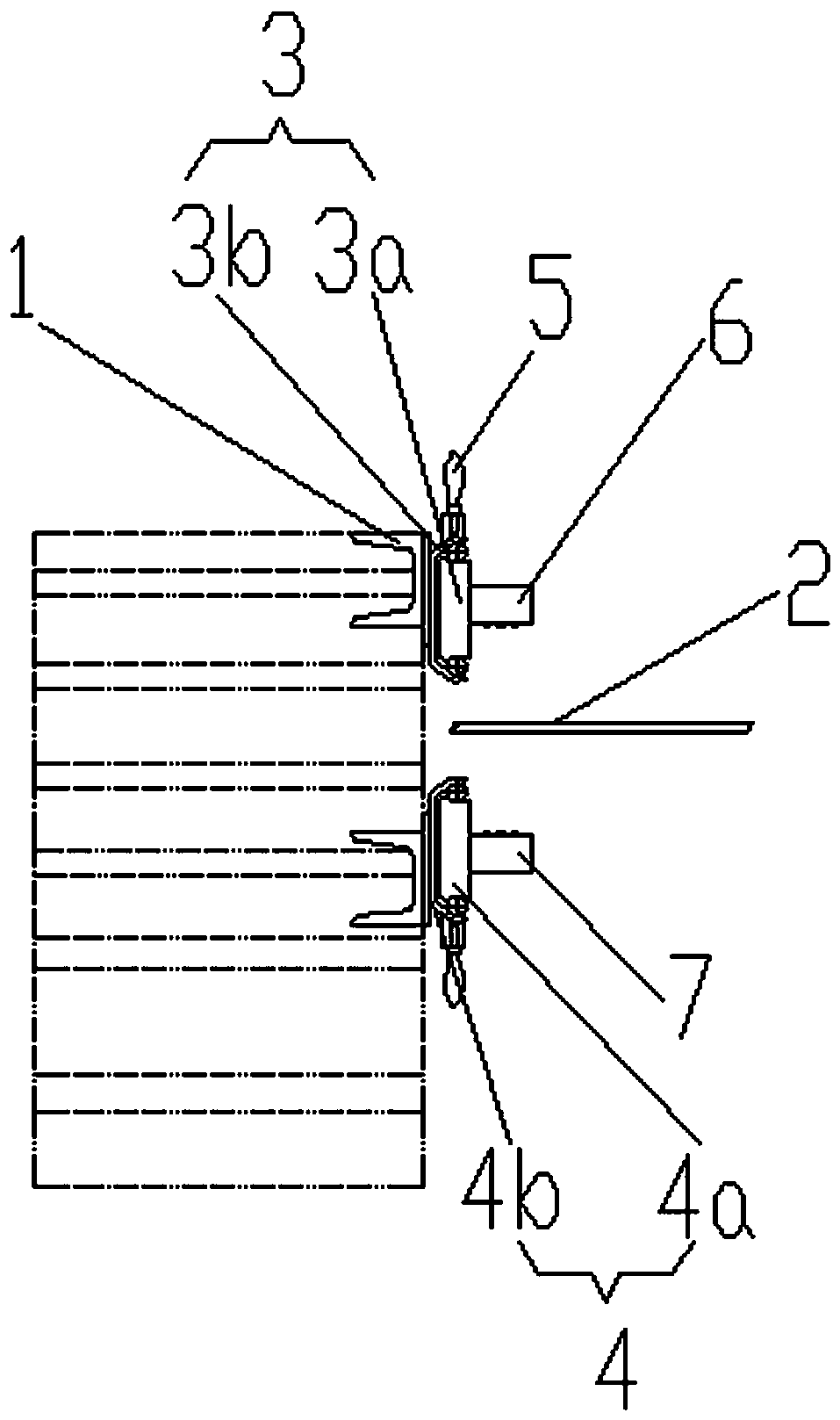

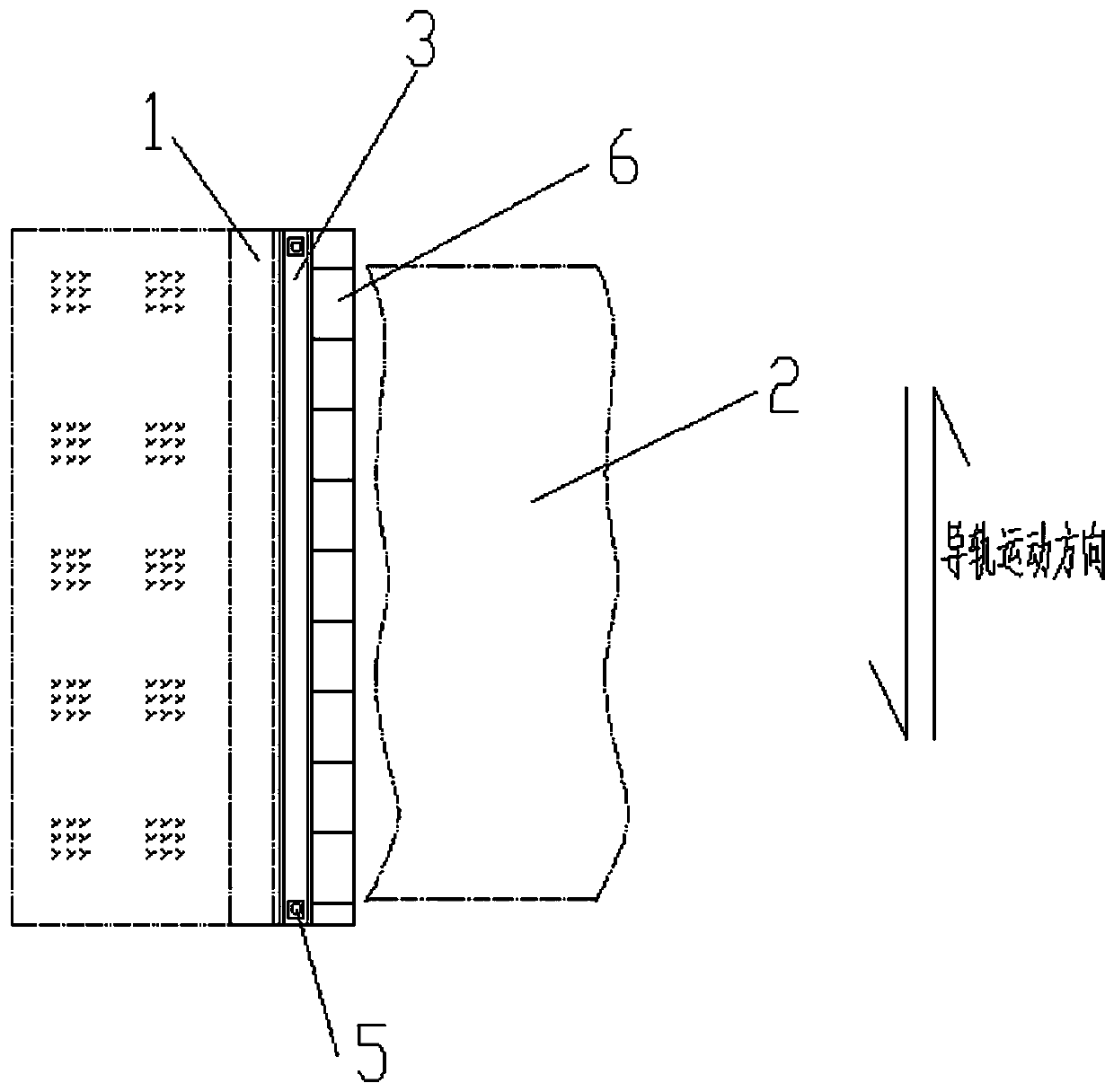

[0015] like figure 1 As shown, a glass ribbon crack alarm device includes a glass ribbon 2 and a steel frame 1 fixed at the exit of an annealing kiln, and is characterized in that:

[0016] A pair of upper linear guide rails 3 and lower linear guide rails 4 with locking blocks 5 are connected to the steel frame 1, and the two are parallel to each other. Including a second slider 4a and a second slide rail 4b;

[0017] The first slide rail 3b and the second slide rail 4b are all connected on the steel frame 1 by bolts, a group of photoelectric transmitters 6 for transmitting continuous optical signals are connected on the first slide block 3a, and a A set of photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com