Method for growing two-dimensional nanostructure through quick physical vapor deposition

A two-dimensional nanostructure and physical vapor deposition technology, applied in the field of nanomaterials, can solve the problems of GeSe nanosheets with large thickness, many impurities, and easy agglomeration, and achieve strong anisotropic photoelectric response characteristics, simple preparation process, high-altitude effect on hole mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

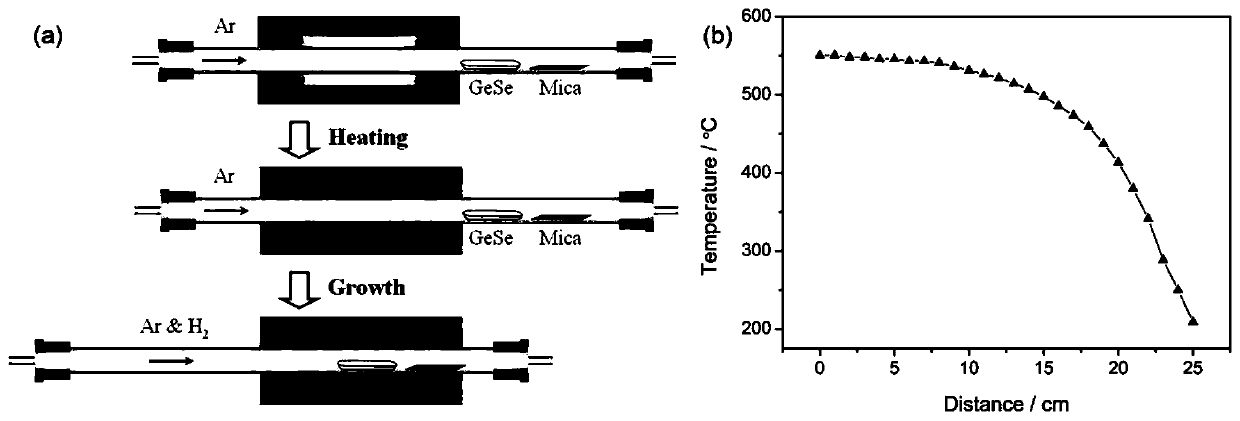

[0025] In this example, high-purity GeSe powder is used as the reaction raw material, a quartz boat is used as the carrier, a 1×6 cm mica sheet is used, argon is used as the carrier gas, and hydrogen is used as the reaction gas as an example.

[0026] A method for growing a two-dimensional nanostructure by rapid physical vapor deposition, comprising the following steps:

[0027] (1) Heating up: place the quartz boat and mica sheet loaded with GeSe powder as the reaction raw material in the quartz tube of the tube furnace, wherein the mica sheet is arranged at a distance of about 14-20 cm downstream of the quartz boat, and then the quartz The tube was fed with argon gas (the flow rate was 50 sccm), and in the atmosphere of argon, the temperature of the quartz tube was raised to 550 °C for about 25 minutes. During the heating process of the quartz tube, the quartz boat containing the GeSe powder and the bottom of the mica sheet were evenly placed outside the tube furnace;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com