Method for preparing transition metal carbide powder through electric field and/or ultrasonic field reinforcement

A transition metal and ultrasonic field technology, applied in the electrolysis process, electrolysis components, etc., can solve the problems of high oxygen content in the product, the reduction of transition metal low-valent oxides and solid solutions, and the difficulty of oxygen removal, so as to achieve high product quality , Strengthen the carbonization kinetic process, and the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

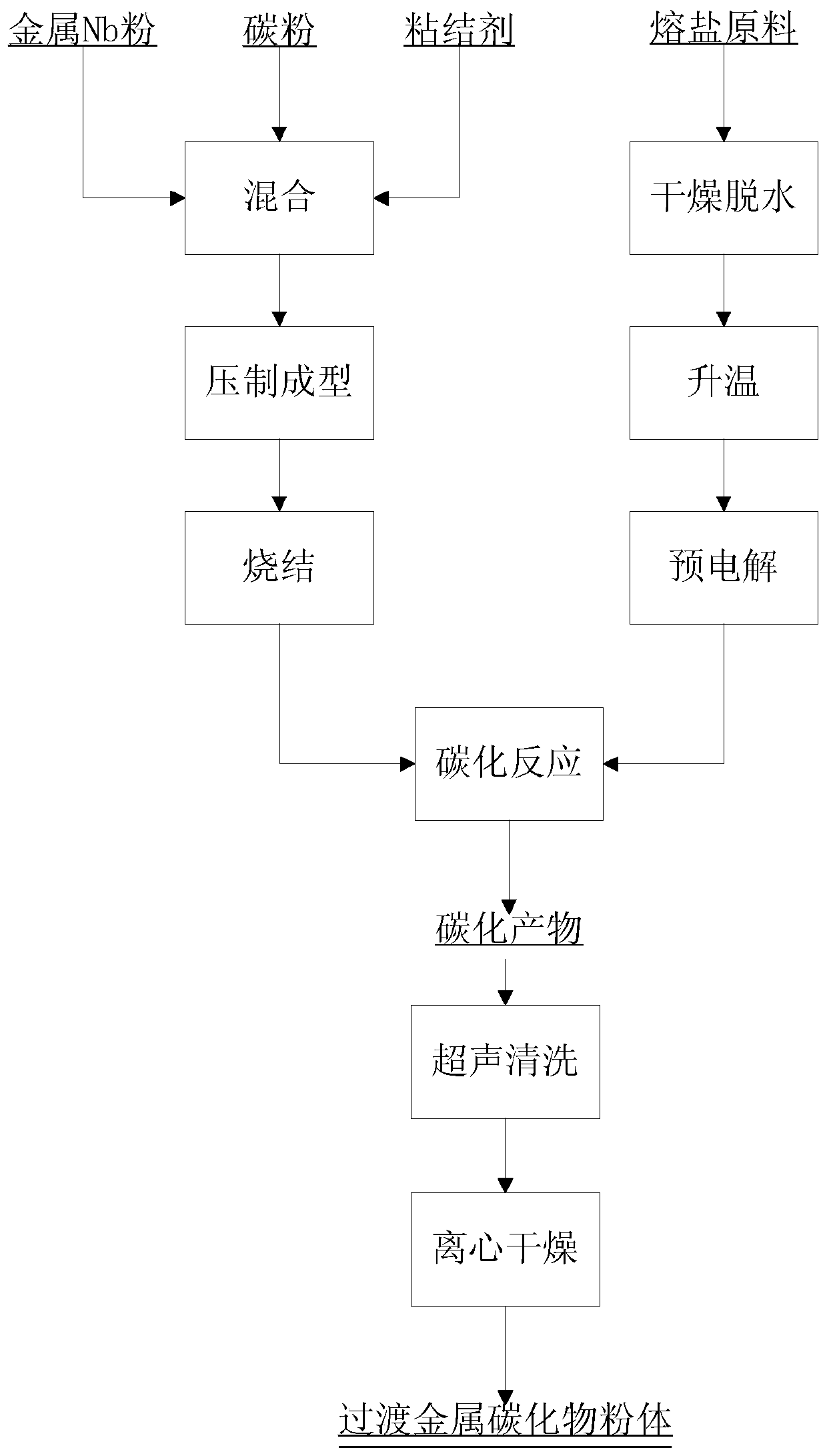

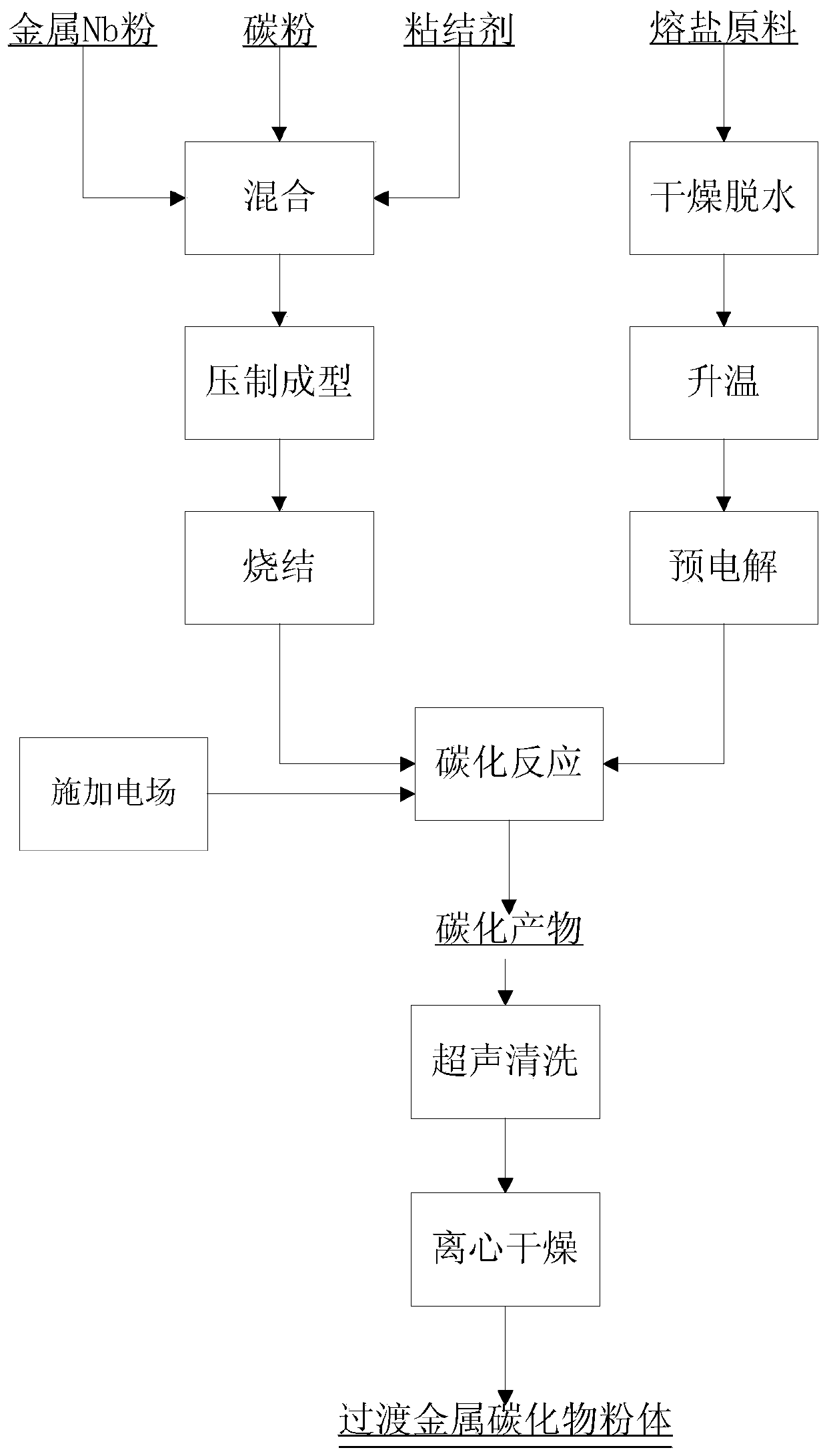

[0086] A method for preparing transition metal carbide powder by electric field strengthening, comprising the following steps:

[0087] Step 1. Preparation of high melting point transition metal-carbon sintered sheet

[0088] (1) Mix metal Nb and amorphous carbon powder according to a molar ratio of 1:1, add polyvinyl alcohol ethanol saturated solution accounting for 2wt% of the total mass percentage of metal Nb and amorphous carbon powder, and mix uniformly to obtain a mixture;

[0089] The metal Nb powder has a particle size of 1 μm, and the amorphous carbon powder has a particle size of 0.2 μm.

[0090] (2) Weighing 2 g of the mixture and molding it under 10 MPa pressure to obtain a cylindrical sheet, the diameter of the cylindrical sheet is 15 cm, and the thickness is 2-3 mm;

[0091] (3) Put the cylindrical sheet in a resistance furnace, and sinter it at 1000° C. for 3 hours under an Ar atmosphere to obtain a high melting point transition metal-carbon sintered sheet.

...

Embodiment 2

[0101] A method for preparing transition metal carbide powder by ultrasonic field strengthening, the same as in Example 1, the difference is:

[0102] (1) In step 3, the high melting point transition metal-carbon sintered piece is connected to the stainless steel wire, the high melting point transition metal-carbon sintered piece is immersed in the molten salt system after pre-electrolysis, and the high melting point transition metal-carbon sintered A 20kHZ ultrasonic field was applied to the stainless steel wire of the sheet through an ultrasonic generator, and the carbonization reaction time was 8h. Compared with Comparative Example 1, ultrasonic vibration can accelerate the diffusion of carbon into the interior of niobium, and eliminate the influence of the natural oxide layer formed on the surface on the kinetics of the carbonization process. At the same time, it can refine the carbide product and obtain carbide powder with a particle size of less than 100nm.

[0103] Other...

Embodiment 3

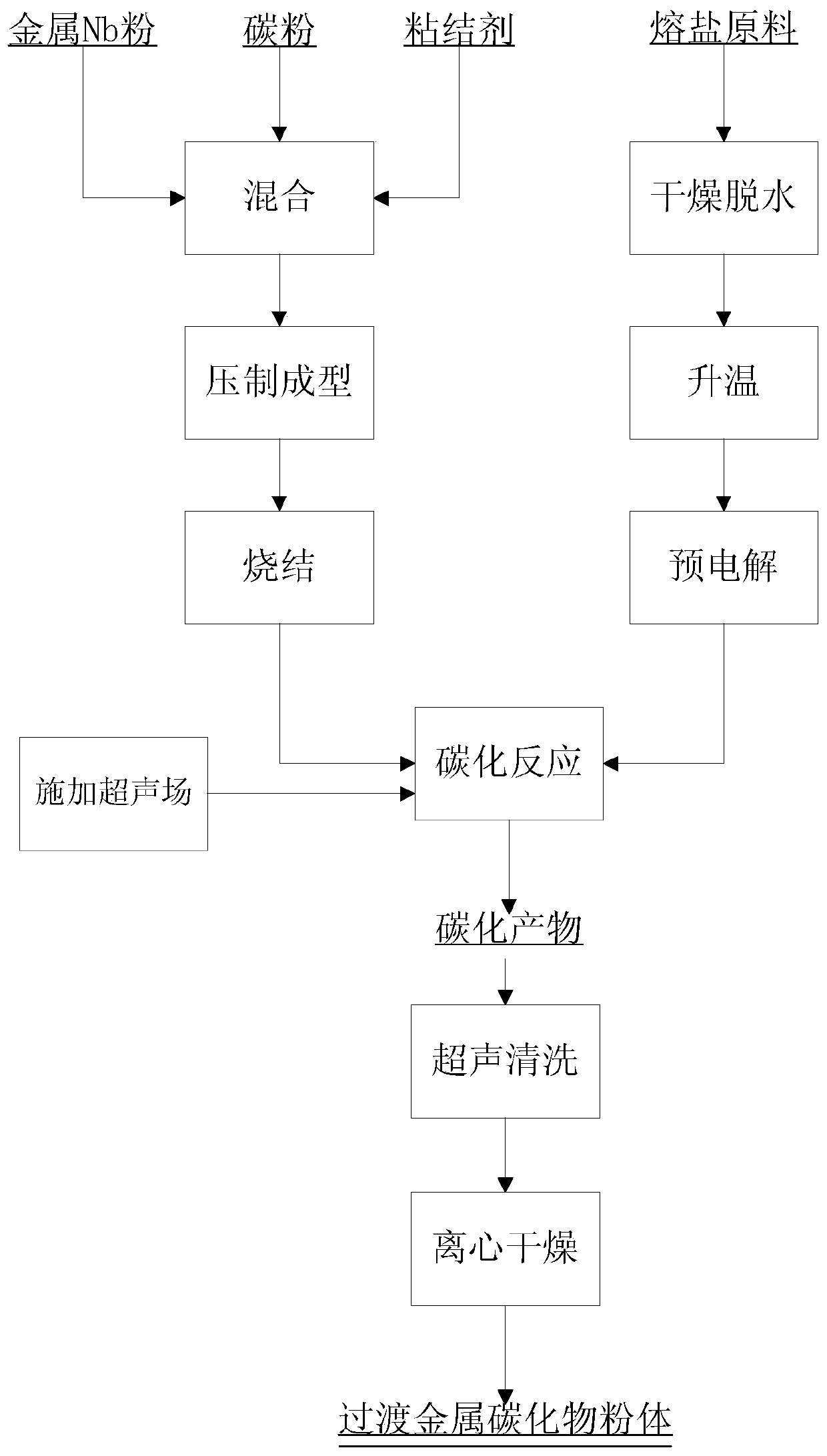

[0106] A method of electro-ultrasonic coupling field strengthening for preparing transition metal carbide powder, the same as in Example 1, the difference lies in:

[0107] (1) While applying the electric field in step 3, use the KMD-K1 ultrasonic generator to apply an ultrasonic field with a frequency of 20kHZ on the stainless steel wire, and the carbonization reaction time is 4h;

[0108] Other implementations are the same.

[0109] The flow chart of the method for preparing NbC by electro-ultrasonic coupled field assisted carbonization is shown in Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com