Turbine stator top sealing limit structure with vane type wire groove

A turbine stator and blade profile technology, applied in the direction of machines/engines, leakage prevention, mechanical equipment, etc., can solve problems such as insufficient sealing ability and blade tip leakage loss, to control leakage loss, reduce clearance leakage, The effect of improving structural reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

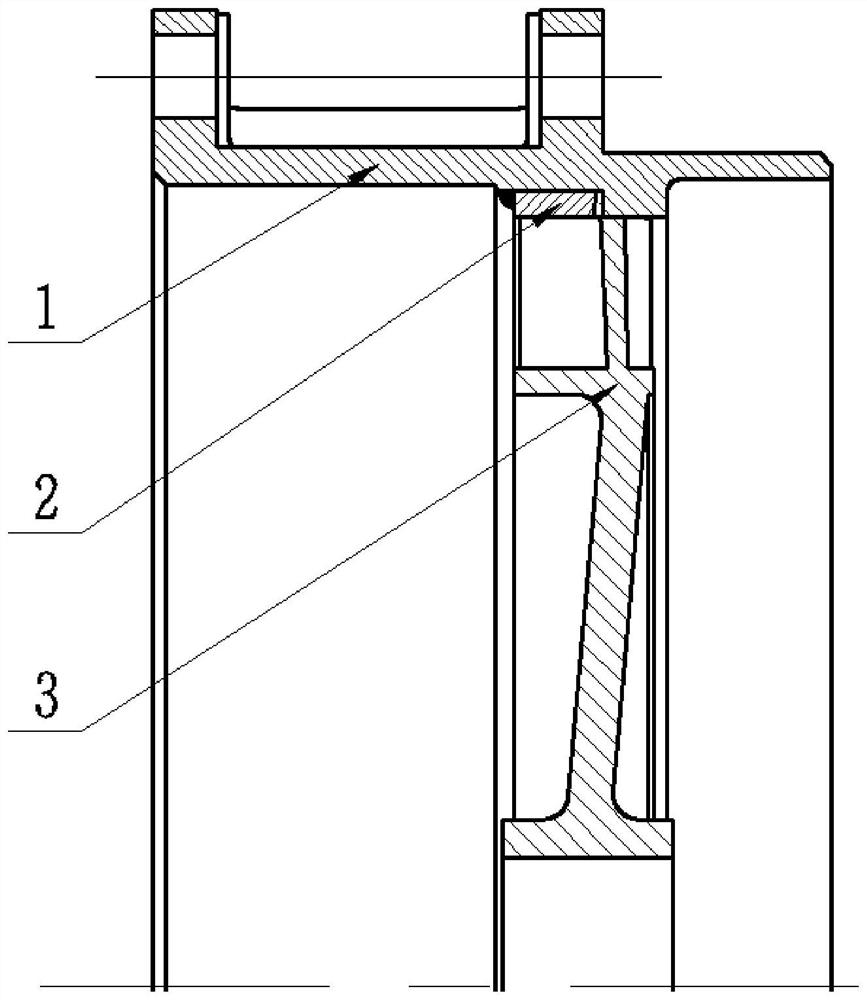

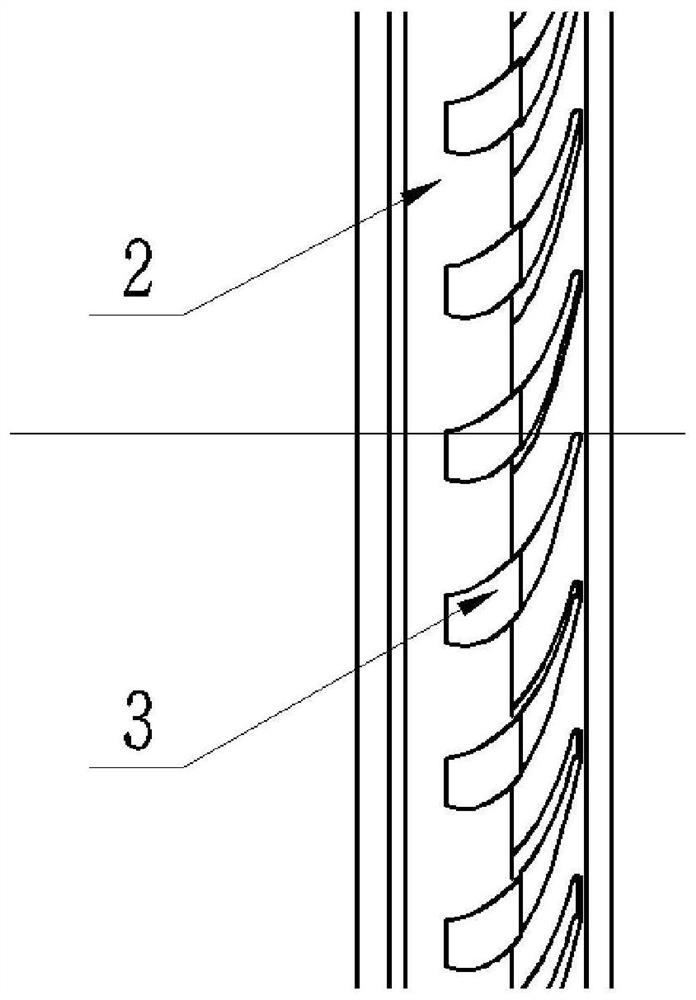

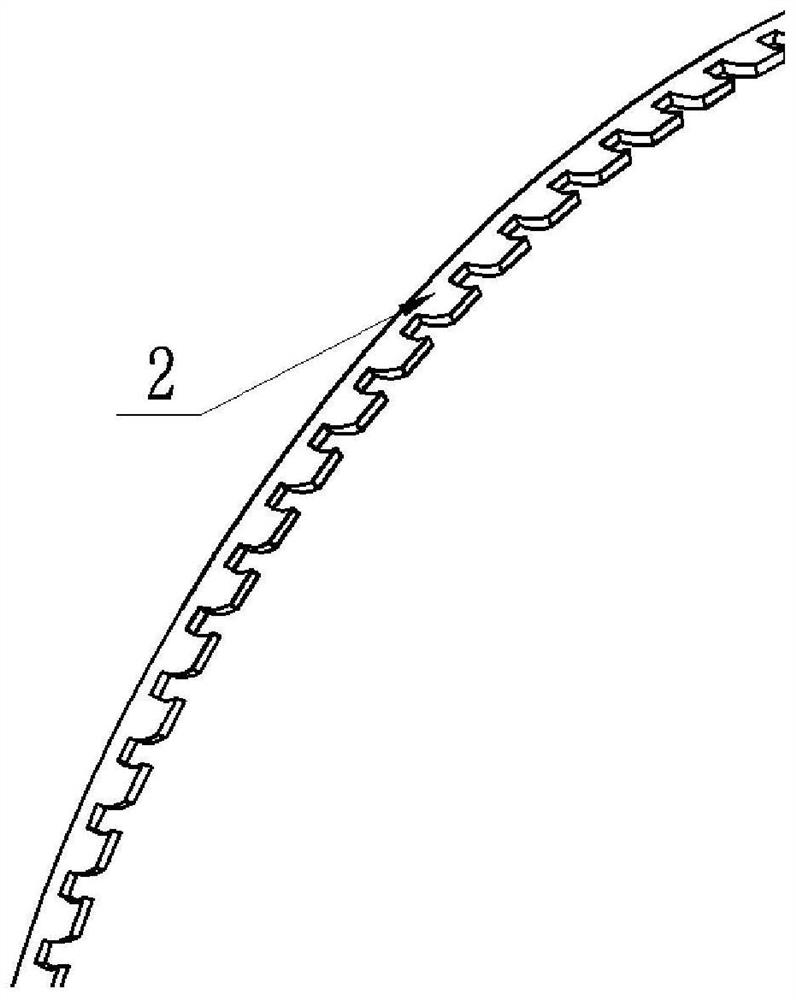

[0021] The invention proposes a sealing and position-limiting structure at the top of a turbine stator with blade-shaped wire slots, which is a new scheme for improving the sealing and position-limiting capability of the top of the turbine stator. Such as figure 1 As shown, the sealing and limiting structure at the top of the turbine stator includes a casing 1 , a sealing and limiting ring 2 and a turbine stator 3 .

[0022] The casing 1 is a hollow structure, and the inner wall is provided with annular steps. The trailing edge and leading edge of the turbine stator 3 blades are processed with steps of the same height. The turbine stator 3 is loaded from the entrance of the casing 1. The ring-shaped step fit in the body 1 limits the movement of the turbine stator 3 to the outlet. The shell 1 and the top of the turbine stator 3 are radially matched with a small gap, and the fit gap is less than 0.03mm; then push the sealing limit ring 2, The sealing limit ring 2 has a groove c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com