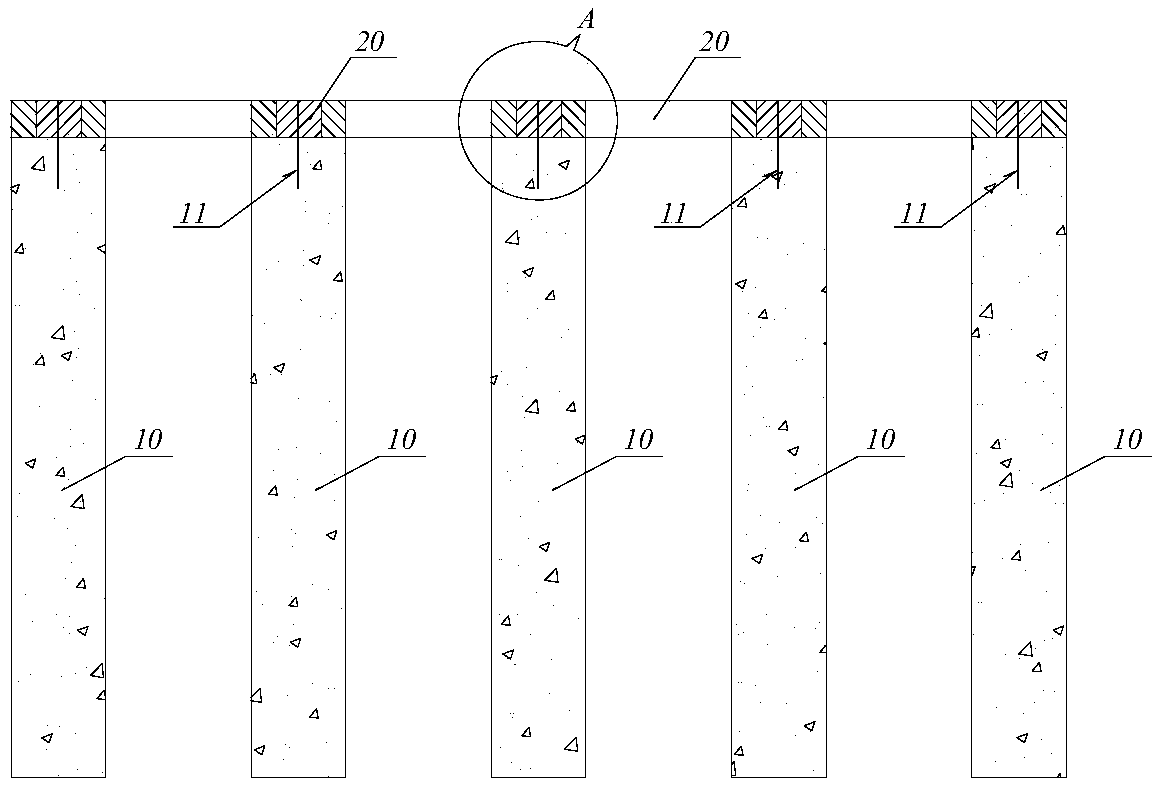

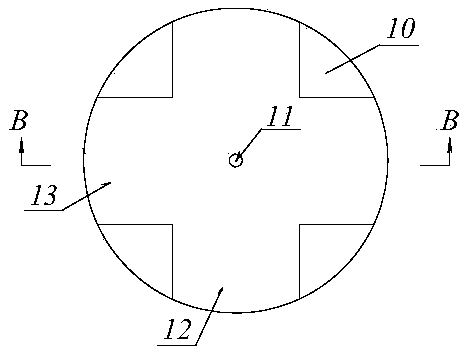

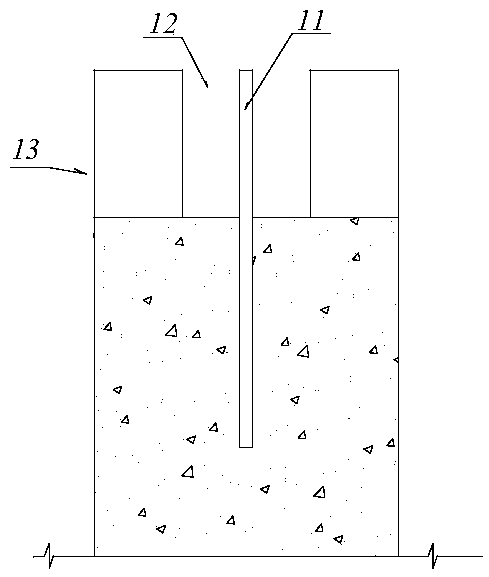

CFG (cement flyash gravel) Pile composite foundation structure and construction method

A composite foundation and foundation technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as construction difficulties, achieve high construction efficiency, low investment, and avoid plane deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0044] For a foundation reinforcement project, the lateral reinforcement width of the foundation is 48m, the reinforcement longitudinal length is 3200m, and the CFG piles are arranged in a square shape with a spacing of 1.6m. The original designed pile cap section size is 1.0m wide, 1.0m long, and 0.6m thick; when frame lattice beams are used, the lattice beam section dimensions are 0.3m wide, 0.3m thick; the unit price of pile cap reinforced concrete is 1500 yuan / m 3 , The unit price of frame lattice beam reinforced concrete is 2000 yuan / m 3 , labor costs 500 yuan / day.

[0045] (1) Comparison of engineering material costs

[0046] 1. Pile cap scheme:

[0047] (1) Number of pile caps: (48 / 1.6+1)×(3200 / 1.6+1)=62031 pieces

[0048] (2) Number of pile cap reinforced concrete: 62031×(1.0×1.0×0.6)=37218.6m 3

[0049] (3) Material cost of pile cap: 37218.6×1500=55827900 yuan

[0050] 2. Frame lattice beam scheme:

[0051] (1) Frame lattice girder longitudinal beam reinforce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com