Superconducting magnet cooling device for superconducting maglev train and its application method

A technology for magnetic levitation trains and superconducting magnets, applied in superconducting magnets/coils, magnetic objects, electrical components, etc., to achieve the effects of reliable refrigeration, weight reduction, and simplification of refrigeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

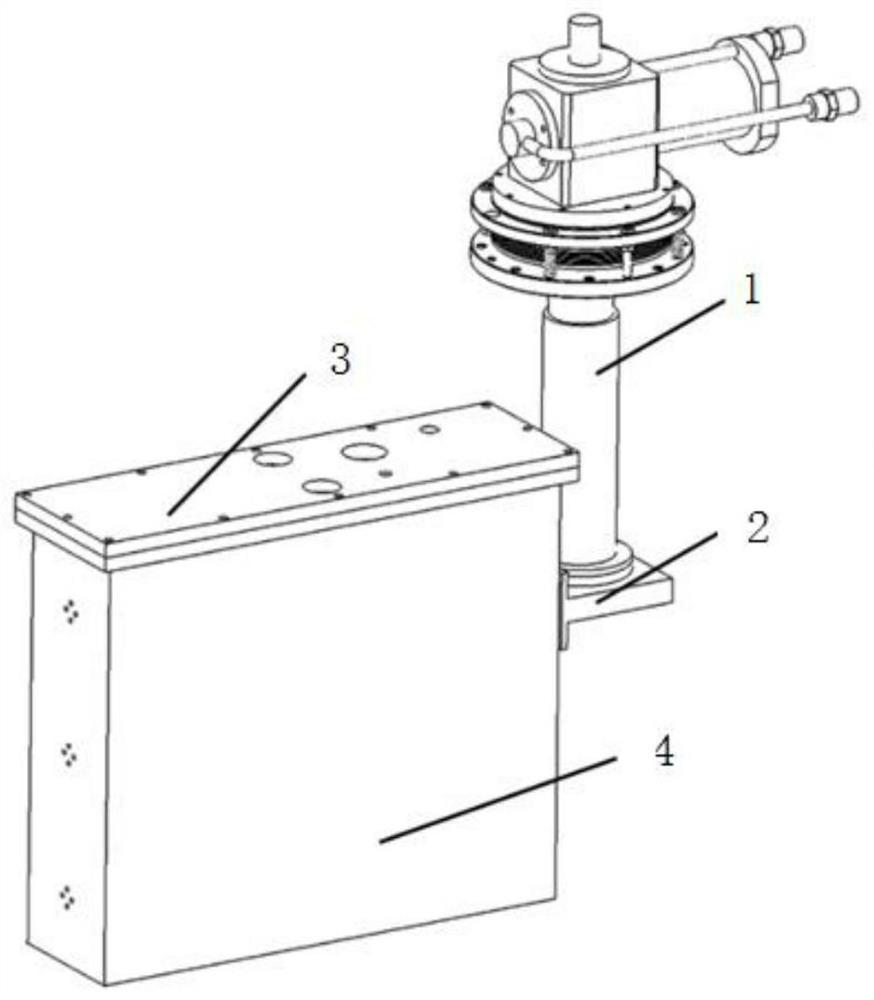

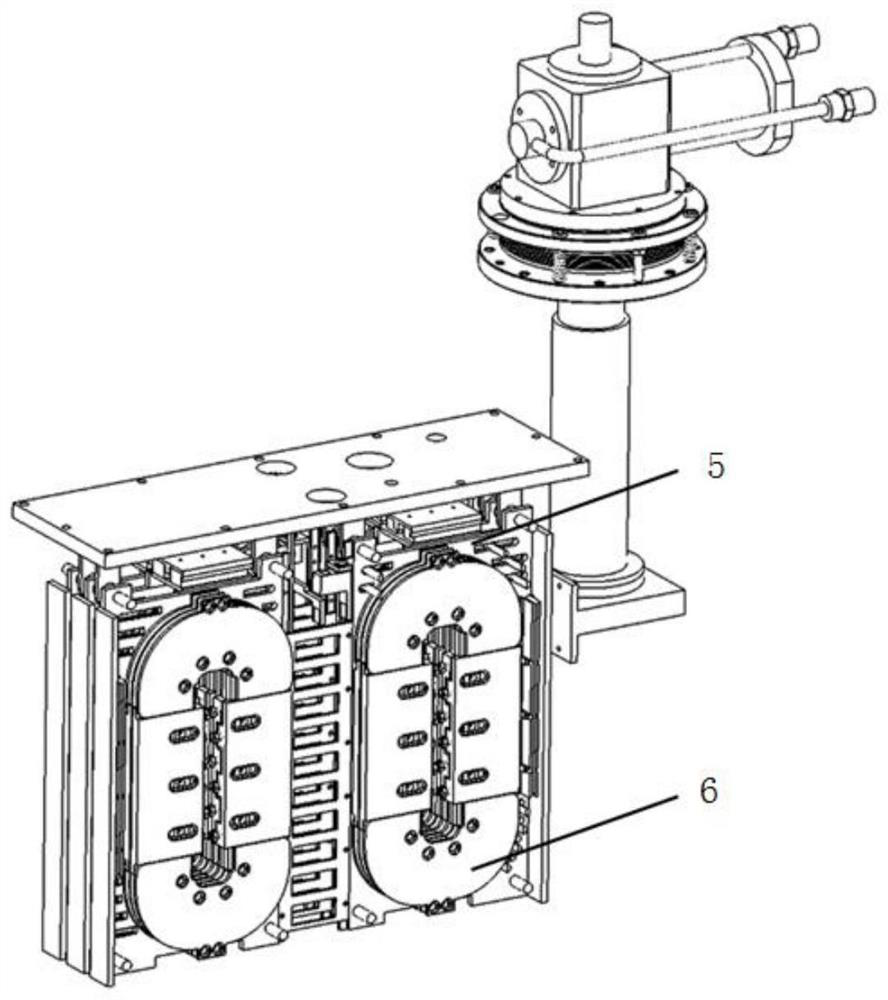

[0033] figure 1 Shown is a schematic diagram of a cooling device of a preferred embodiment of the present invention, figure 2 yes figure 1 The internal structure diagram of the cooling chamber shown.

[0034] figure 1 The cooling device shown includes a cryogenic refrigerator 1, a cooling plate 2 and a cooling cavity; one end of the cooling plate 2 is connected to the cryogenic refrigerator 1, and the other end is connected to the cooling cavity; a superconducting magnet 6 is installed in the cooling cavity.

[0035] The low-temperature refrigerator 1 of this embodiment is directly connected to the cooling plate 2, and the cooling plate 2 is directly connected to the cooling cavity, and directly conducts the cooling capacity of the low-temperature refrigerator 1 to the cooling cavity, and has a simple structure and is suitable for low-temperature refrigerators. 1 Make the working temperature of the superconducting magnet 6 be the nitrogen fixation temperature range of 20K-...

Embodiment 2

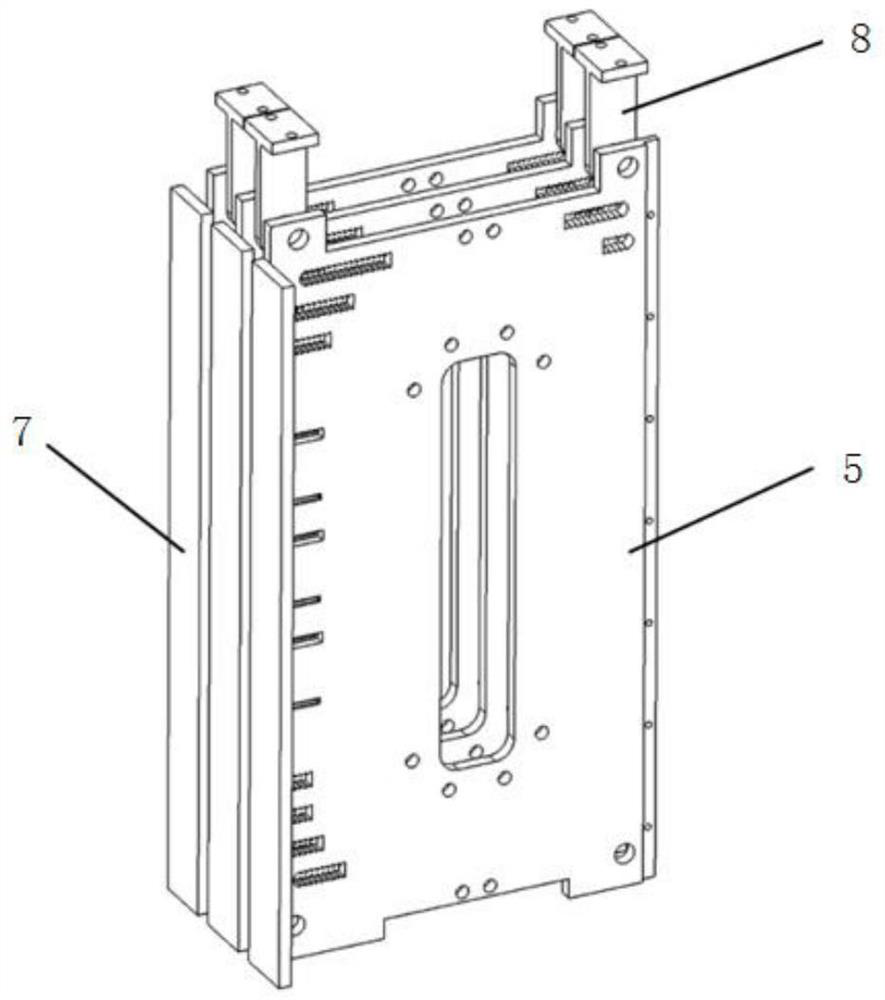

[0045] image 3 Shown is the cold guide plate structure of another preferred embodiment of the present invention.

[0046] Considering the inevitable vibration during the traveling process of the maglev train applied in the present invention and when the train leaves the track and returns to the track, in order to prevent the vibration from causing the superconducting magnet 6 to shift in the cooling chamber, the traditional method is fixed by various fixing structures. Magnets in a maglev train. However, in the traditional method, the number of structures to fix the magnet is positively correlated with the quality, and too many and heavy fixing structures not only affect the heat dissipation effect of the superconducting magnet 6, but also increase the weight load of the train, which reduces the operating efficiency of the train, and Operating speed and passenger capacity are also affected accordingly. In order to solve the vibration problem of the maglev train, and the con...

Embodiment 3

[0050] This embodiment describes in detail the usage method of the superconducting magnet cooling device of the superconducting maglev train of the present invention through specific experiments.

[0051] Step 1. Install the superconducting magnet in the cooling chamber, close the cooling chamber and evacuate it;

[0052] Step 2: Turn on the low-temperature refrigerator, and directly conduct cooling through the cooling plate to cool the cooling cavity, so that the superconducting magnet is cooled to the working temperature.

[0053] In step 1, firstly, the sealed cooling chamber installed with the superconducting magnet 6 is evacuated to avoid water vapor condensation. After the vacuum is exhausted, the low-temperature refrigerator 1 is turned on, and the cold energy is transferred to the superconducting magnet 6 through the close contact of the cooling plate 2, the cooling chamber and the superconducting magnet 6, and the superconducting magnet 6 is cooled to below operating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com