A roll-to-roll manufacturing method of vertical graphene

A manufacturing method and graphene technology, which is applied in the manufacture of hybrid/electric double layer capacitors, semiconductor devices, circuits, etc., can solve problems such as not being able to take advantage of physical properties, and achieve efficient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

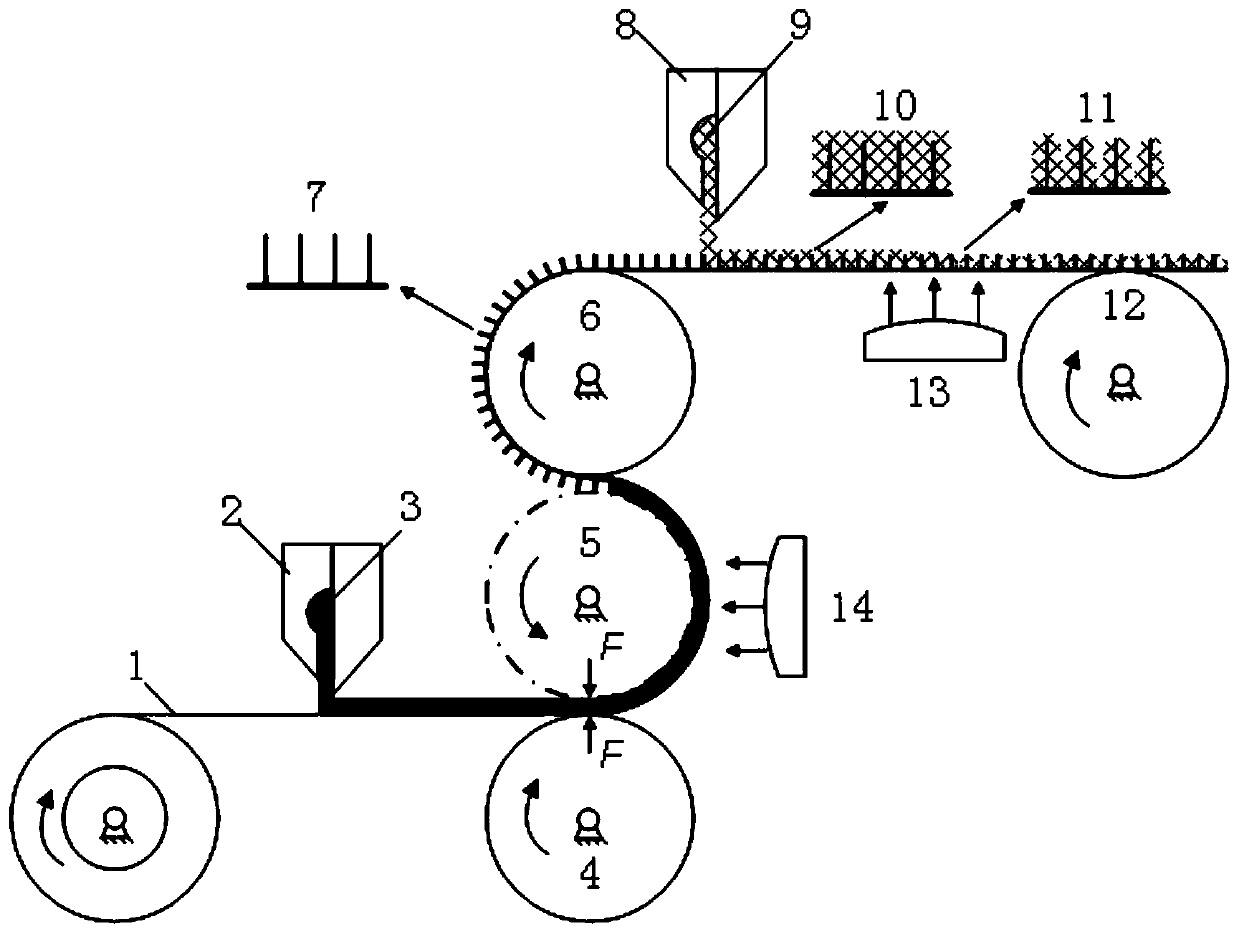

[0021] like figure 1 Shown, a roll-to-roll manufacturing method of vertical graphene comprises the following steps:

[0022] 1) Continuous roll embossing of microstructures with large aspect ratio: the roll-packed PI flexible film 1 is tensioned and stretched between extrusion roll 4, mold roll 5, release roll 6 and tension roll 12 as the microstructure For the flexible substrate, use the feeding scraper 2 to evenly coat the 0.1mm thick ultraviolet light curing glue UV glue 3 on the flexible film 1, and the thickness of the UV glue 3 is determined by the distance between the first feeding scraper 2 and the flexible film 1 It is determined that the UV glue 3 is embossed and shaped by the mold roller 5, cured after being exposed to the ultraviolet lamp 14 for 300s, and demolded by the release roller 6 to form a flexible microstructure array 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com