High-heat-dissipation bus duct structure

A technology of busway and high heat dissipation, which is applied in the direction of cooling busbar device and fully enclosed busbar device, which can solve the problems of high manufacturing cost, poor heat dissipation performance, unreliable conductive connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

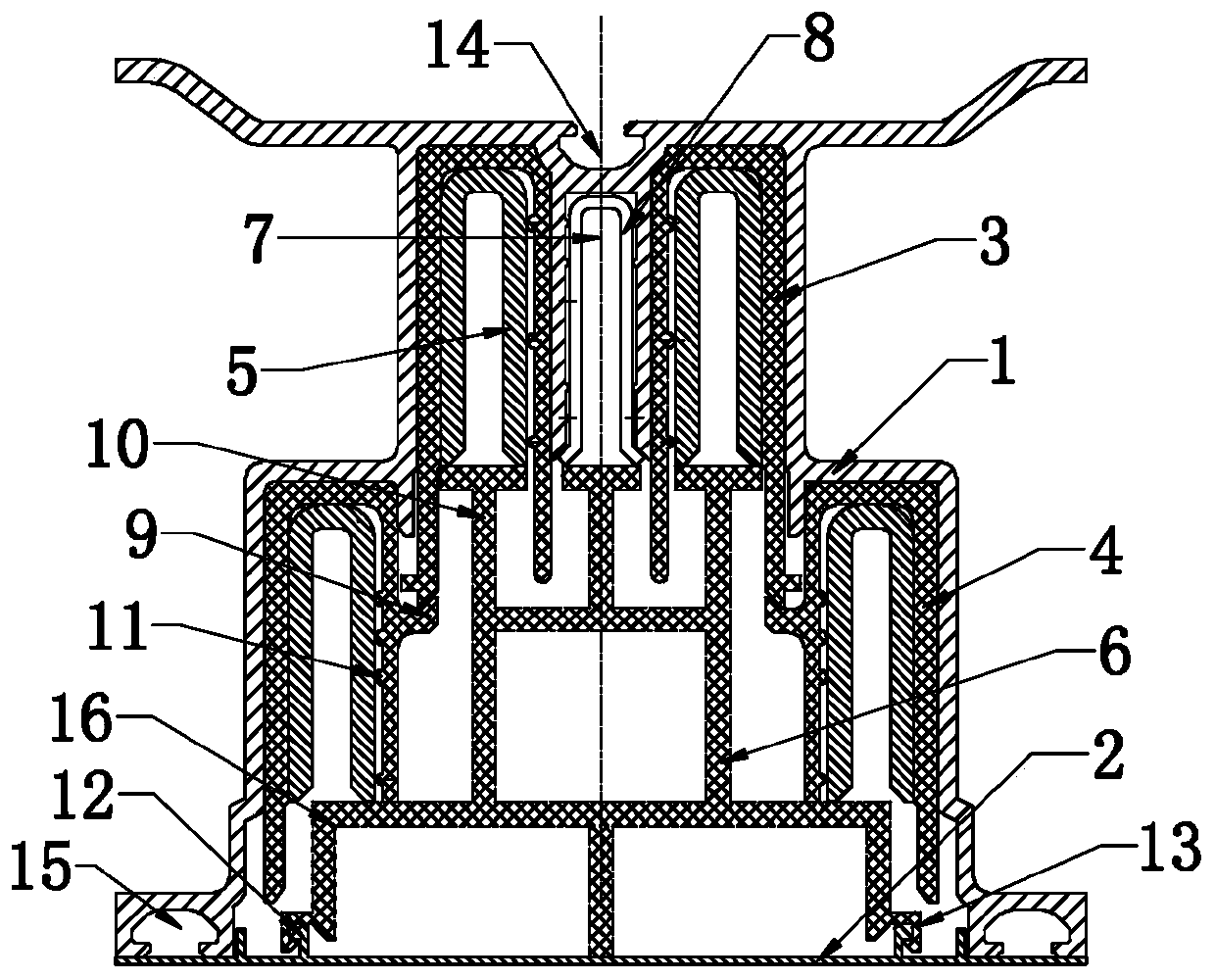

[0015] The high heat dissipation busway structure of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] As shown in the figure, the high heat dissipation busway structure of the present invention includes a casing 1 with a convex cross-sectional shape and a cover plate 2 installed at the bottom opening of the casing. Radiation teeth can be arranged outside the casing. The middle part of the casing 1 There is a U-shaped card slot 7 formed by two plates extending from the top to the bottom of the cavity. A grounding conductor 8 is placed in the U-shaped card slot 7. The inner cavity of the upper half of the housing 1 (the top protruding part in the convex structure) ) is divided into two left and right housing cavities by the U-shaped card slot 7 from the middle, and a U-shaped upper insulator 3 is respectively placed in the left and right two cavities, and the inner cavity of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com