Sustained release fibers

A fiber and polymer technology, applied in the field of sustained release fibers, which can solve problems such as inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Material

[0084] sheath material : Nylon 6-6 (80% to 90% by weight) from INVISTA, which contains nylon 6 (3-9%), TiO2 (1-8%), polystyrene (1-2%)

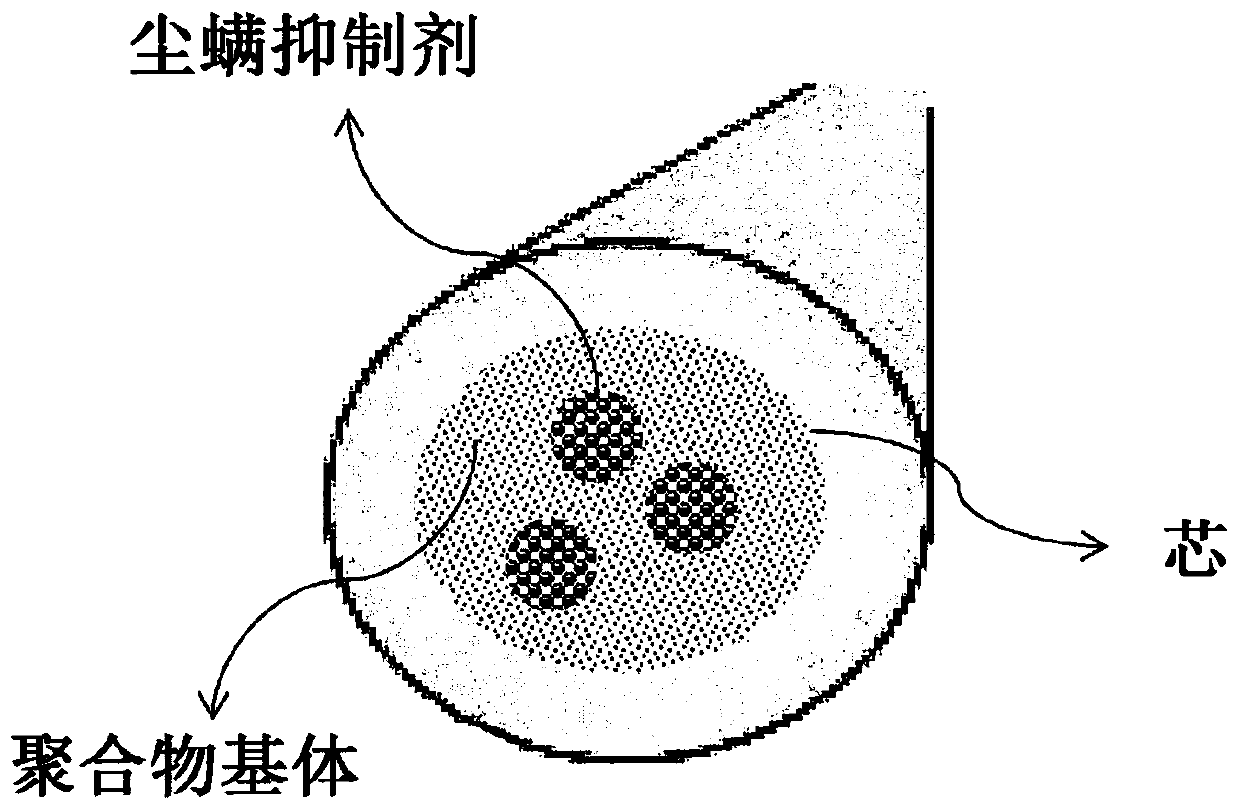

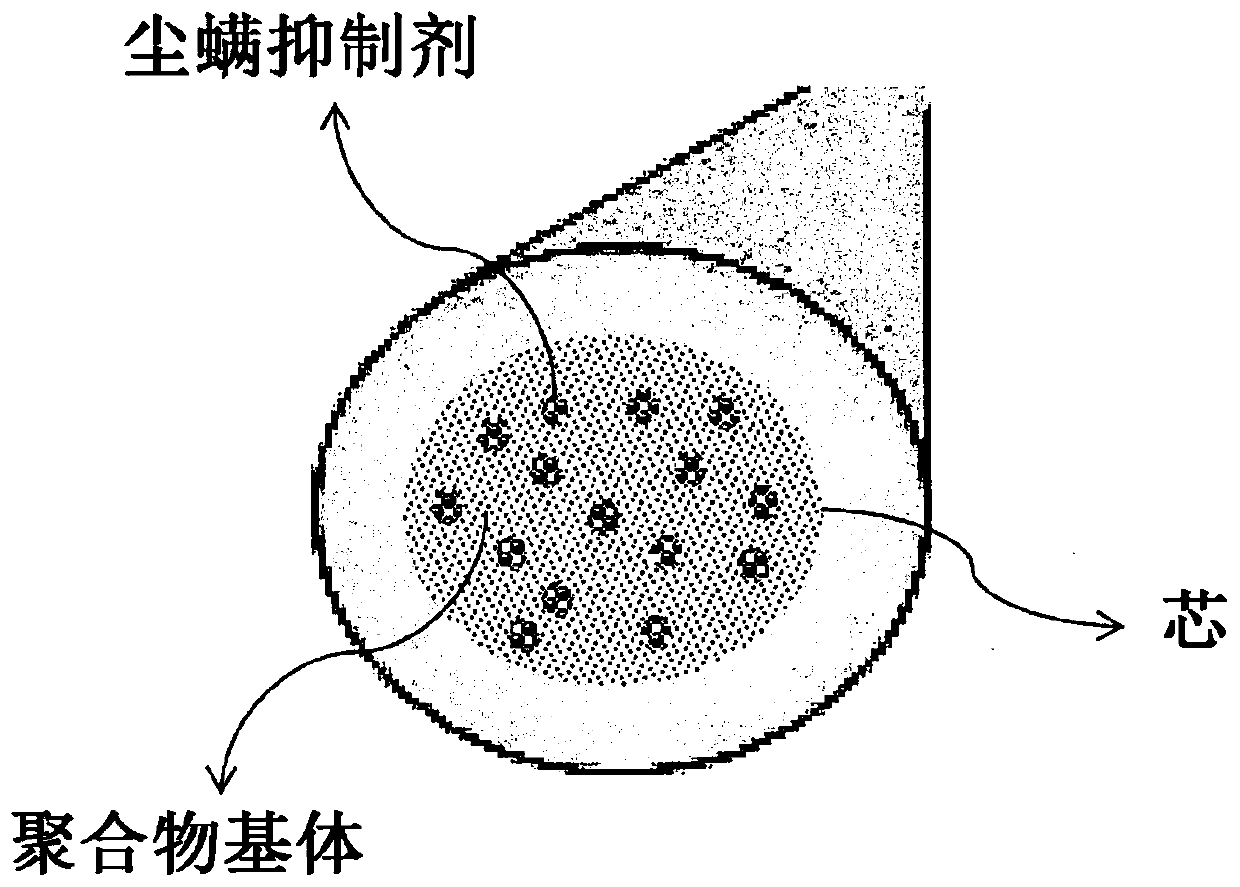

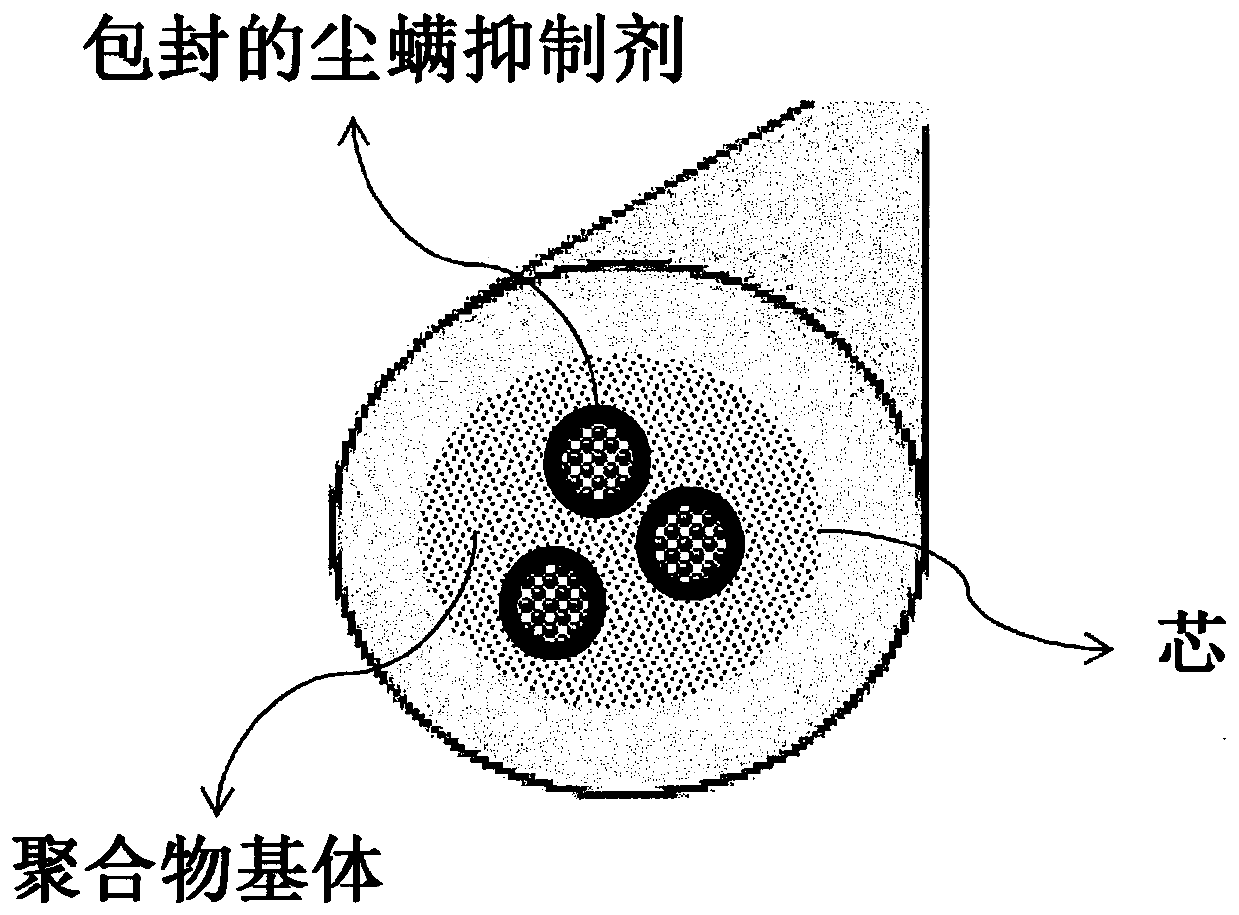

[0085] core material: SROPE-DZ from Kuraray Living Co. Ltd., Japan, which contains 20% by weight of salicylic acid encapsulated using polyethylene / polypropylene-polystyrene block copolymer and distributed in a polyethylene (PE) matrix phenyl esters.

[0086] When analyzed by thermogravimetric analysis (TGA), SROPE-DZ was observed to lose 14.91% of its weight within 20 minutes at 170°C, which may be attributed to the loss of phenyl salicylate. When the temperature was raised to 285°C, a loss of 36.8% by weight was observed, which could be attributed to both the loss of phenyl salicylate and some degradation of the polyvinyl matrix.

[0087] preparation :

[0088] To prevent or reduce loss of phenyl salicylate or degradation of the polyvinyl matrix, the core extruder temperature was adjusted. The extruder consists ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com