Brake disc hubs and discs with improved vehicle interface

A technology for brake discs and vehicles, applied in the direction of brake discs, brake components, brake types, etc., can solve the problems of complex assembly process of brake disc manufacturing methods, and achieve the effect of eliminating easy distortion and simplifying cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

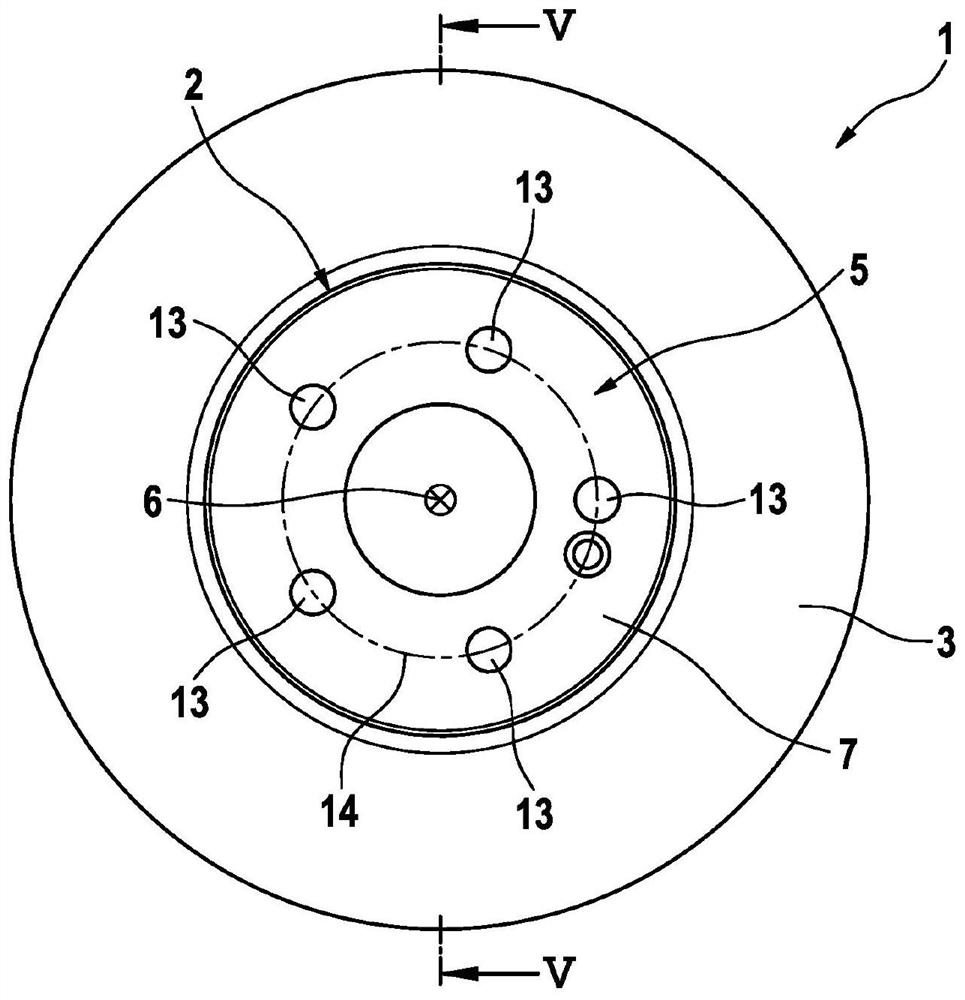

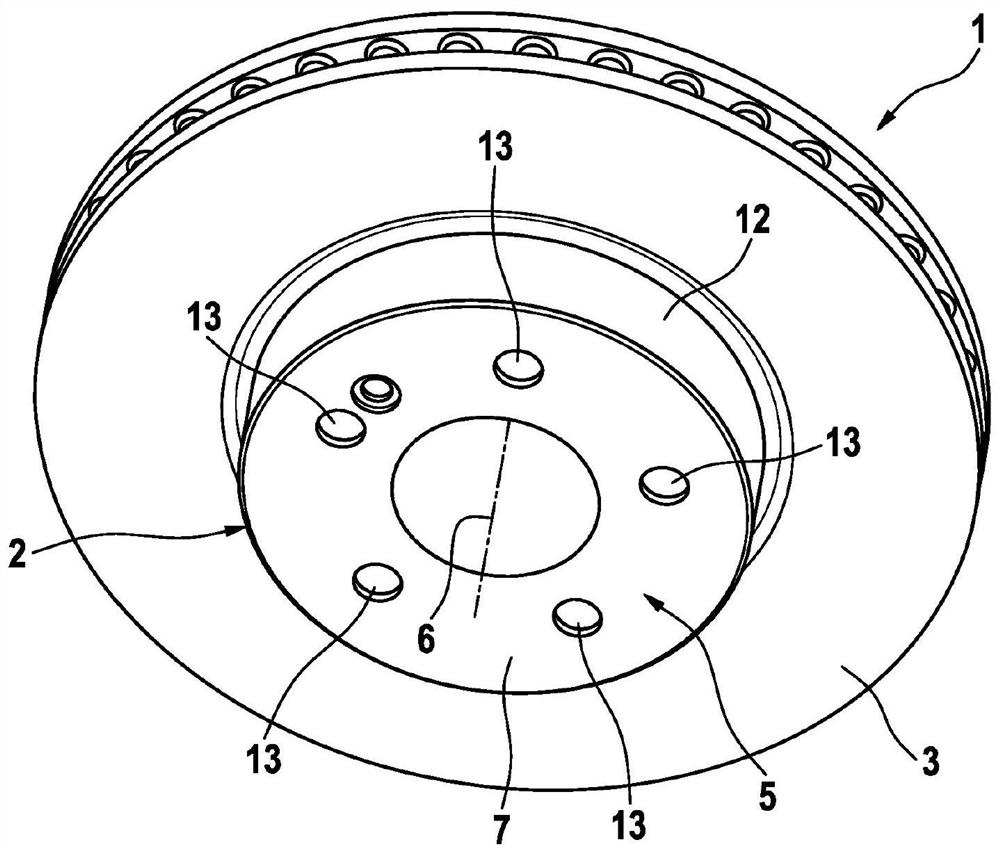

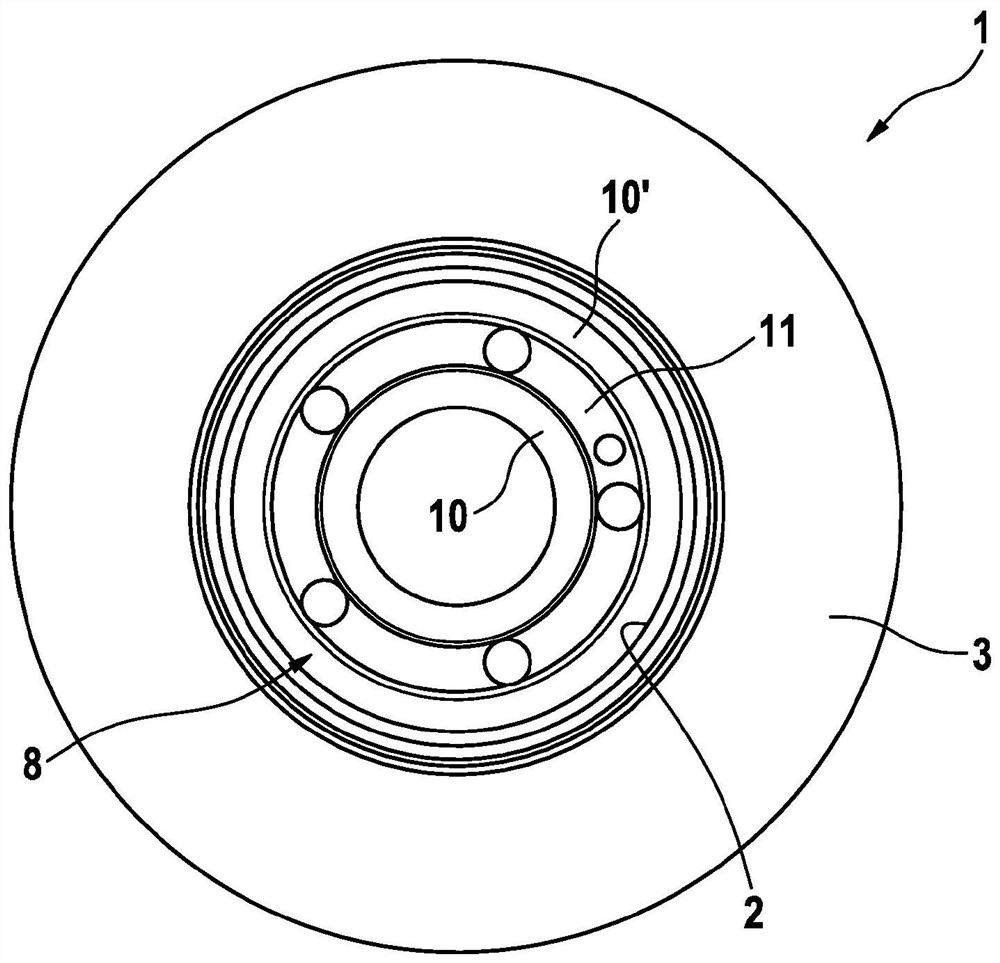

[0023] figure 1

[0024] The embodiment of the brake disc 1 according to the invention is substantially rotationally symmetrical with respect to the wheel axis of rotation 6 and has a cup-shaped / pot-shaped brake disc hub 2 and a radially outwardly extending Friction ring 3 protruding from the brake disc hub. In the embodiment shown, the brake disk 1 is produced in one piece from a casting. A multi-part embodiment of the brake disc 1 consisting of a brake disc hub 2 and a friction ring 3 connected to each other via an interface is also acceptable in the present invention, however, the brake disc hub 2 is particularly preferably formed in a shaped manner, especially Manufactured by casting techniques rather than by deformation methods.

[0025] The brake disk hub 2 has a hub base 5 with an outer side 7 for bearing against a wheel, not shown. In the hub base 5 there are provided a plurality of through-holes 13 arranged on a common indexing disk 14 and arranged offset from one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com