Full-automatic opening and closing horizontal supercritical fluid foaming equipment

A technology of supercritical fluid and foaming equipment, which is applied in the methods of chemically changing substances by atmospheric pressure, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as unfavorable safety production and industrialization, and achieve loading and unloading operations. Improves, facilitates cleaning, and improves operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 tank body sealing process

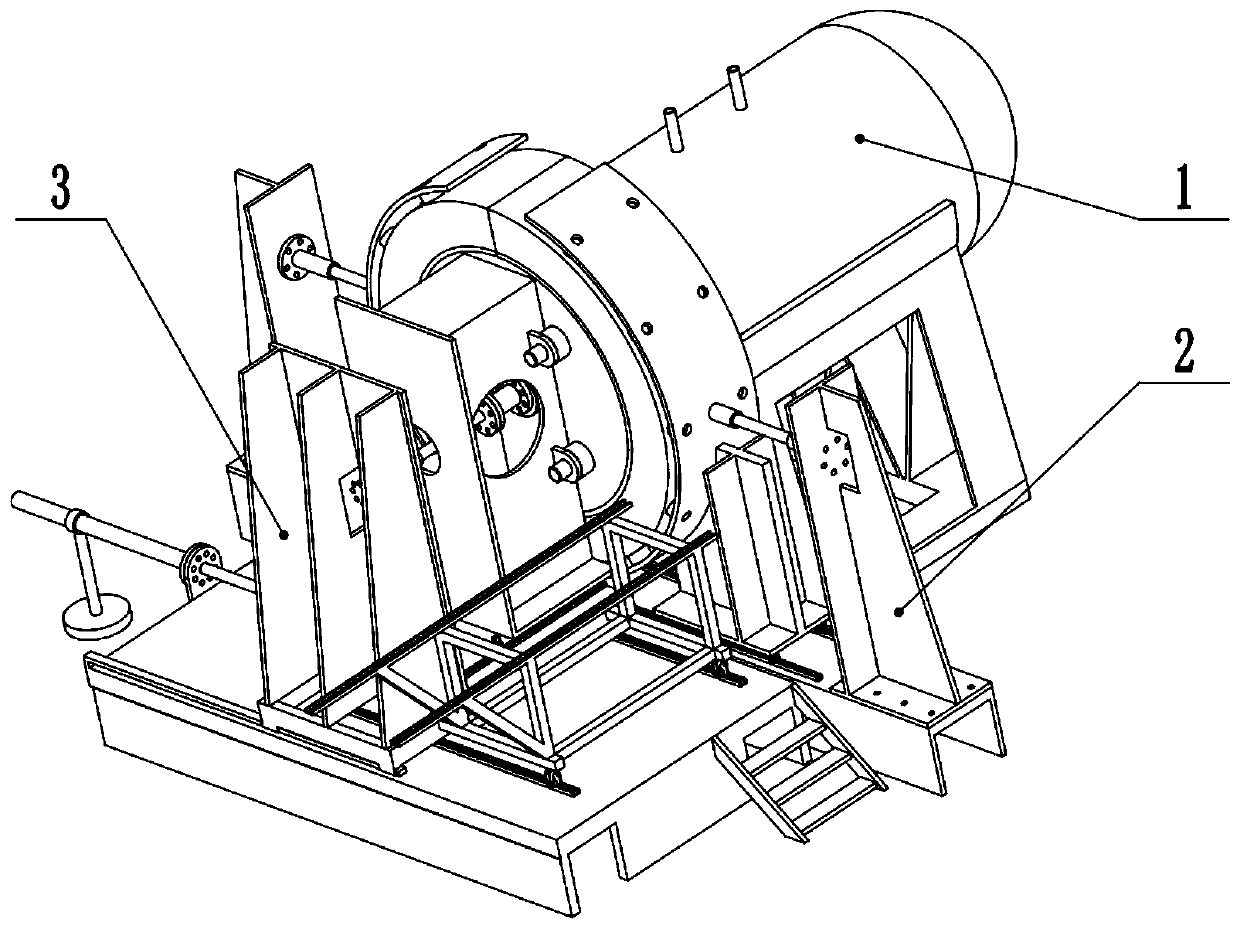

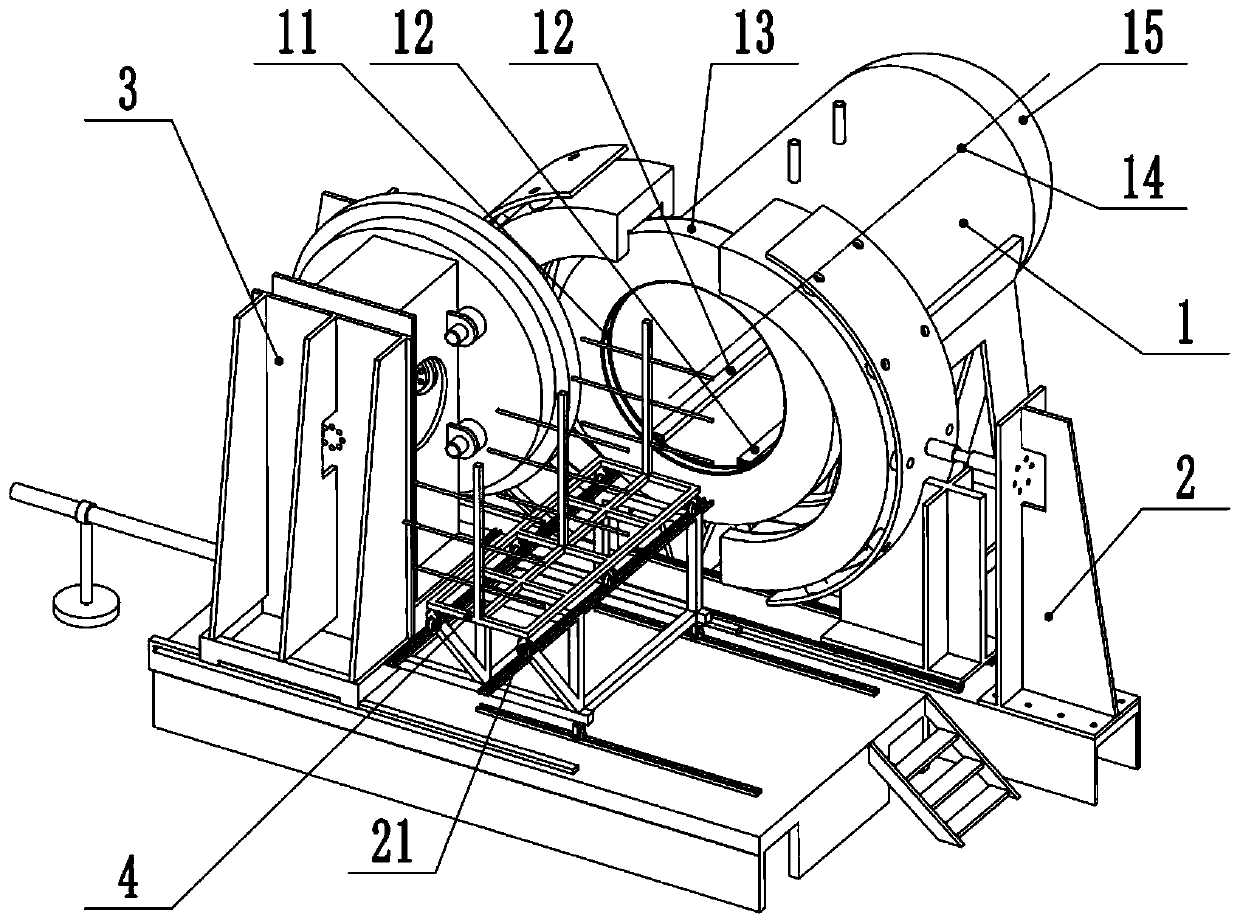

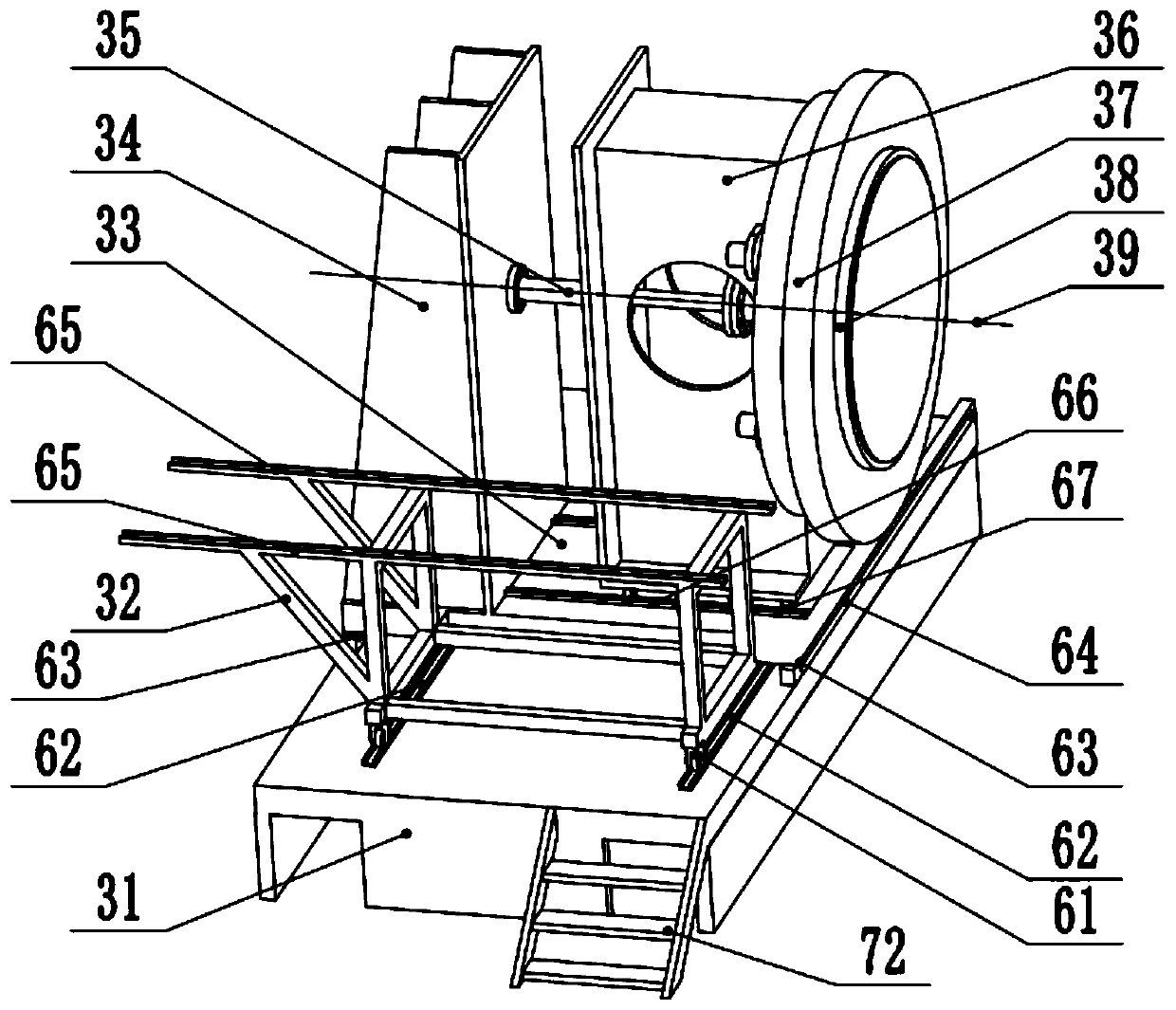

[0037] Refer to attached figure 1 to attach Figure 5 , hang the material on the material rack (4), when the material introduction rack (32) is aligned with the center of the tank body assembly (1), push the material introduction rack (32) into the tank body, and the material introduction rack (32) After starting to enter the tank body, move along the inner track (12) of the tank, and start the automatic control closing device when all the material introduction racks (32) enter the tank body;

[0038] First the hydraulic device C (70) starts to work and pushes the support frame base plate (33) to move laterally towards the tank mouth. When the center line (14) of the tank body is aligned, the hydraulic device C (70) stops moving;

[0039] Then the hydraulic device A (35) starts to work, and the combined structure of the end cover support frame (36) and the end cover (37) is promoted to move towards the tank body, and the gaske...

Embodiment 2

[0042] Embodiment 2 tank opening process

[0043] Refer to attached figure 1 to attach Figure 5 , when the equipment needs to be opened, the hydraulic device B (45) starts to work, pulls a pair of clamps (47) to move outward, and locks the clamp locking end (74) in the grooved part of the clamp (47) The combination with the locking end (13) of the tank body is released;

[0044] Then the hydraulic device A (35) starts to work, and pulls the combined structure of the end cover support frame (36) and the end cover (37) to separate from the tank body. In order to prevent the end cover (37) from interfering with the clip (47) when moving laterally, After the end cover (37) moves to the outer surface of the clip (47), the hydraulic device A (35) stops moving;

[0045] Then the hydraulic device C (70) starts to work, pulling the support frame bottom plate (33) to move laterally away from the tank mouth, until the support frame bottom plate (33) moves to the limit block (68) posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com