Feeding method and automatic feeding mechanism of bending machine

An automatic feeding and bending machine technology, applied in the field of bending machines, can solve problems such as affecting the feeding process, increasing production costs, and low work efficiency, and achieving the effects of high production efficiency, fast feeding, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

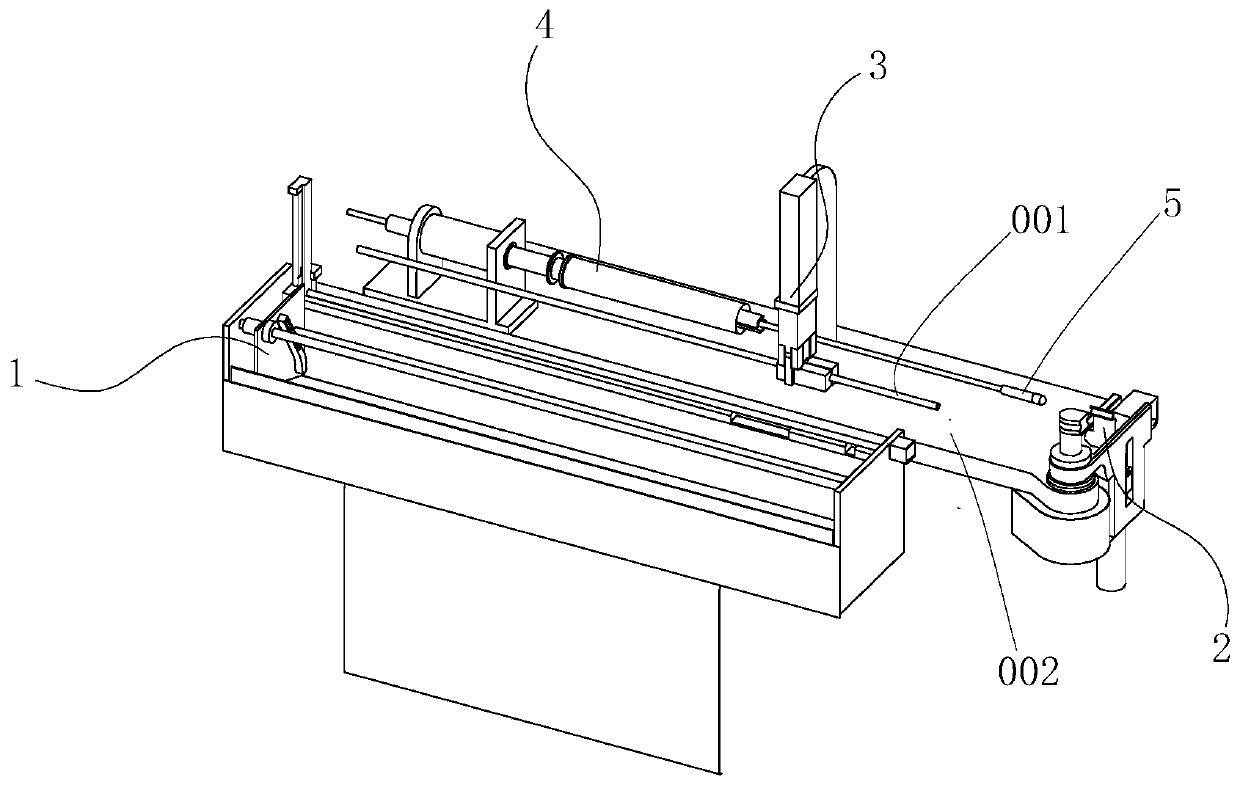

[0032] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] The invention provides a method for feeding a bending machine, which comprises the following steps:

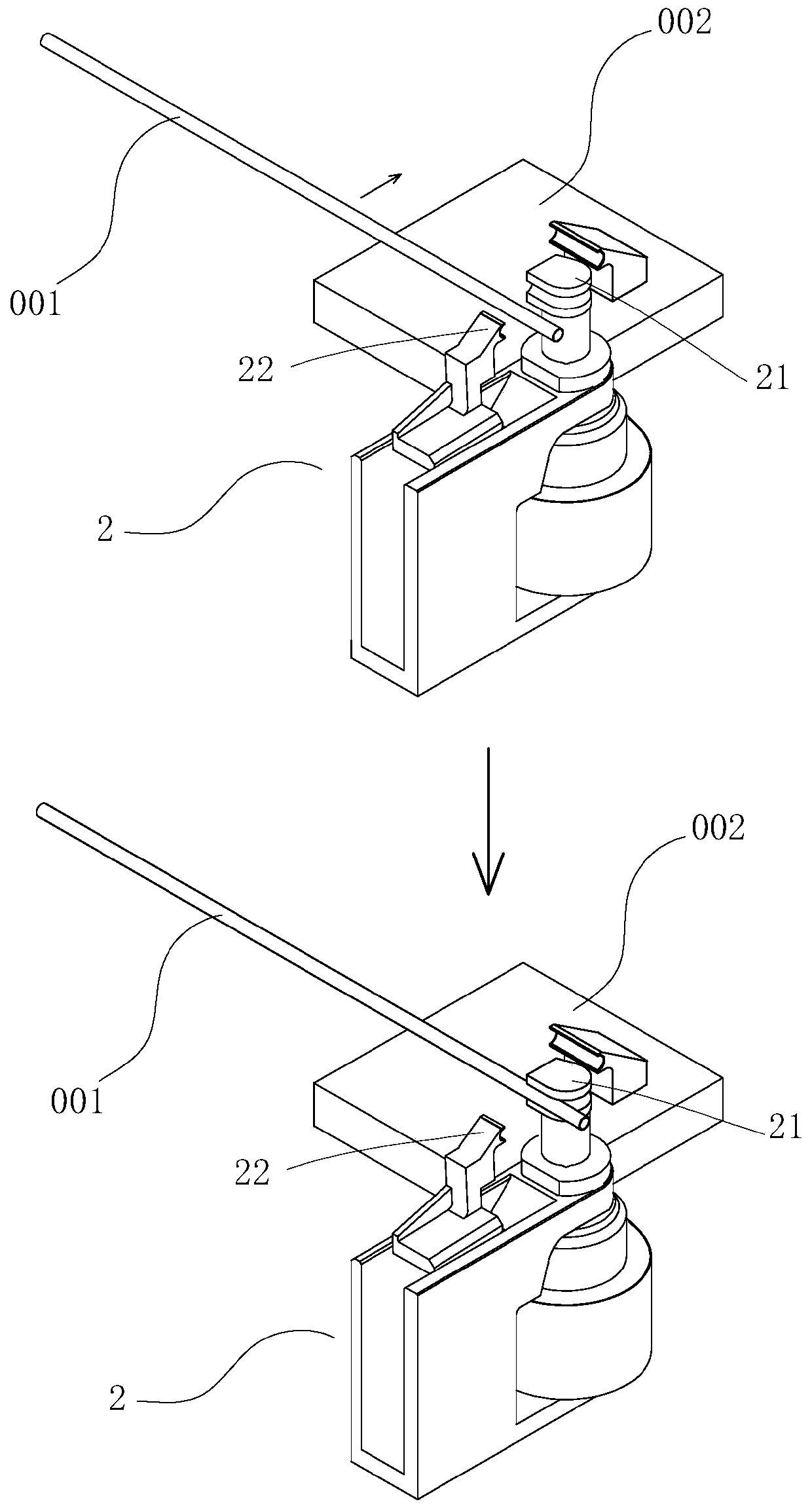

[0034] S1. The clamping device 2 of the bending machine is rotated 180° from the initial position to the receiving position;

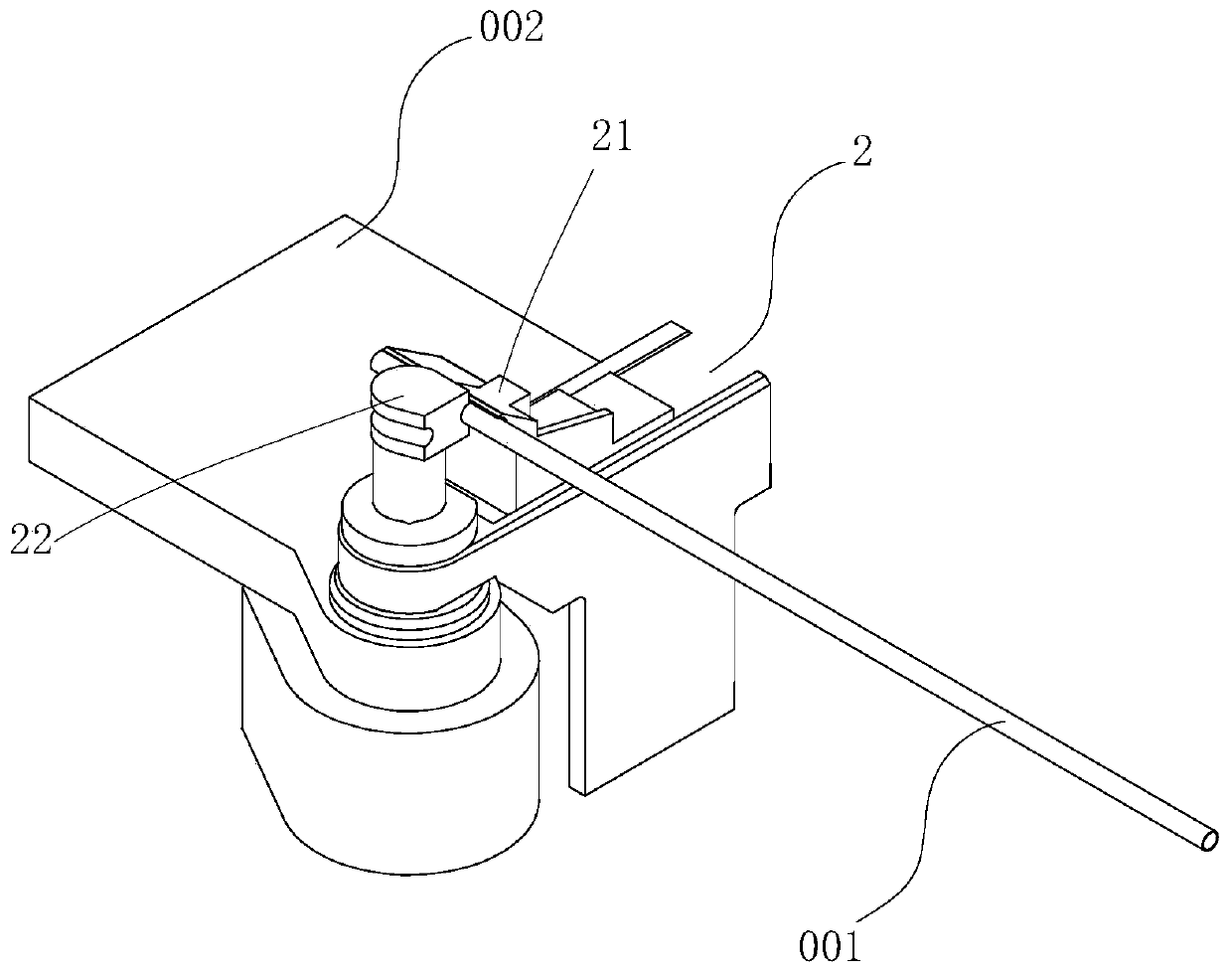

[0035]S2. Translate and place the tube or bar 001 at the round die 21 of the clamping device 2, and then the clamping unit 22 of the clamping device 2 acts to clamp the tube or bar 001; preferably The specific operation process of translating and placing the tube or bar 001 at the circular die 21 of the clamping device 2 is as follows: first translate the tube or bar 001 along its axis direction, and then move the tube or bar 001 001 is placed at the circular die 21 along the direction perpendicular to its axis;

[0036] S3, the clamping device 2 is reversely rotated 180° from the receiving position to retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com