Automatic leather product surface treatment equipment

A surface treatment and equipment technology, applied in the field of automatic leather surface treatment equipment, can solve the problems of incomplete manual grinding, affecting the quality of leather shoes, poor polishing stability, etc., and achieve the effect of reducing labor workload, reducing labor costs and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

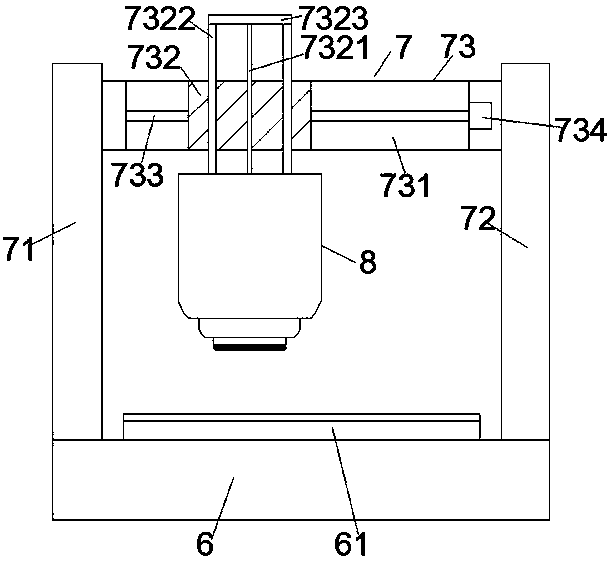

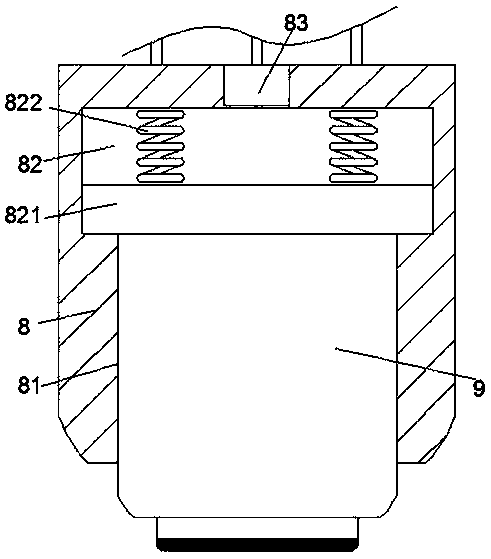

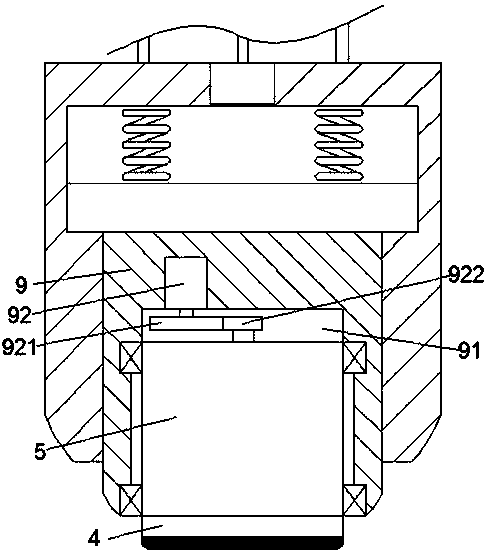

[0019] Combine below Figure 1-5 The present invention will be described in detail.

[0020] refer to Figure 1-5 , according to an embodiment of the present invention, an automated leather surface treatment equipment, including a support base 6, a support frame body 7 arranged on the top of the support base 6, and a polishing machine body 8 arranged in the support frame body 7, and Including the polishing head body 4, the polishing machine body 8 is provided with a first inner chamber 82 and a first sliding chamber 81 with the opening downward, and the top end of the first sliding chamber 81 is connected with the first inner chamber 82 Through setting, the positioning buffer block 821 is connected with the sliding fit in the first inner cavity 82, and the buffer spring 822 is connected with the press fit on the top of the positioning buffer block 821, so as to improve the stability of the polishing operation, and the first sliding The cavity 81 is slidingly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com