Tunnel pillar underground excavationreverse construction underground structure and construction method

A technology of underground structure and construction method, which is applied in underground chambers, earthwork drilling, wellbore lining and other directions, can solve the problems of high cost, slow construction speed, and difficult construction, and achieves control of differential settlement, accelerated construction speed, and improved construction. Difficulty reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

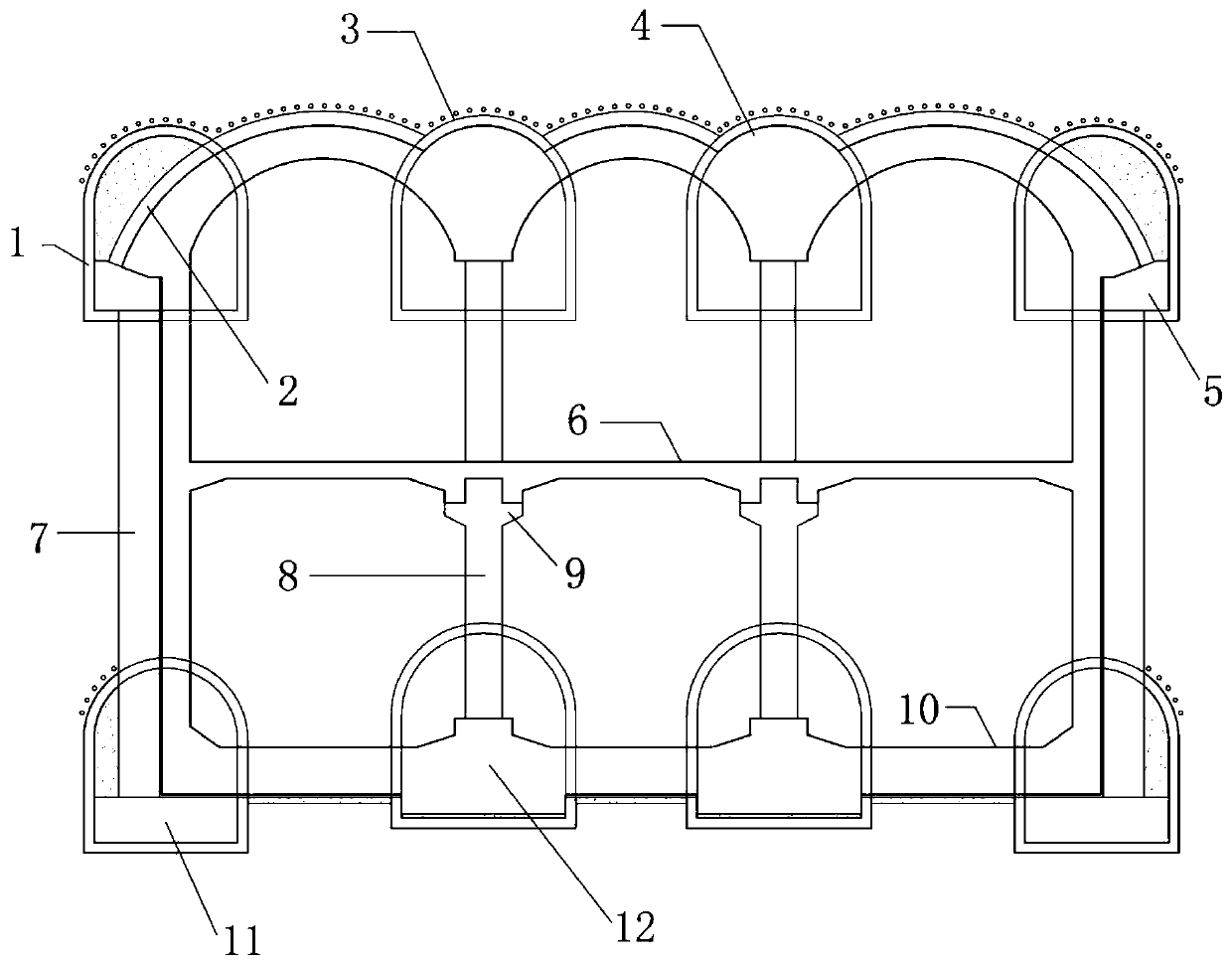

[0057] This embodiment provides an underground structure with underground excavation and upside-down construction of holes and pillars. Please refer to figure 1 and Figure 11 , this kind of tunnel column underground structure includes an upper pilot tunnel, a lower pilot tunnel, a main arch primary support 2, a permanent column 8, a top longitudinal beam 4, a bottom longitudinal beam 12 and a bottom plate 10;

[0058] Pilot tunnels are only set on the 10th floor of the main arch and bottom plate, and the number of transverse directions is determined according to the number of spans of the proposed underground space and the transverse column network. ) guide holes. In this embodiment, the proposed underground structure has three spans, and two pilot tunnels are respectively set at the center column, combined with the pilot tunnels on both sides, that is, there are four upper pilot tunnels and four lower pilot tunnels on a transverse section.

[0059] Both the upper pilot tun...

Embodiment 2

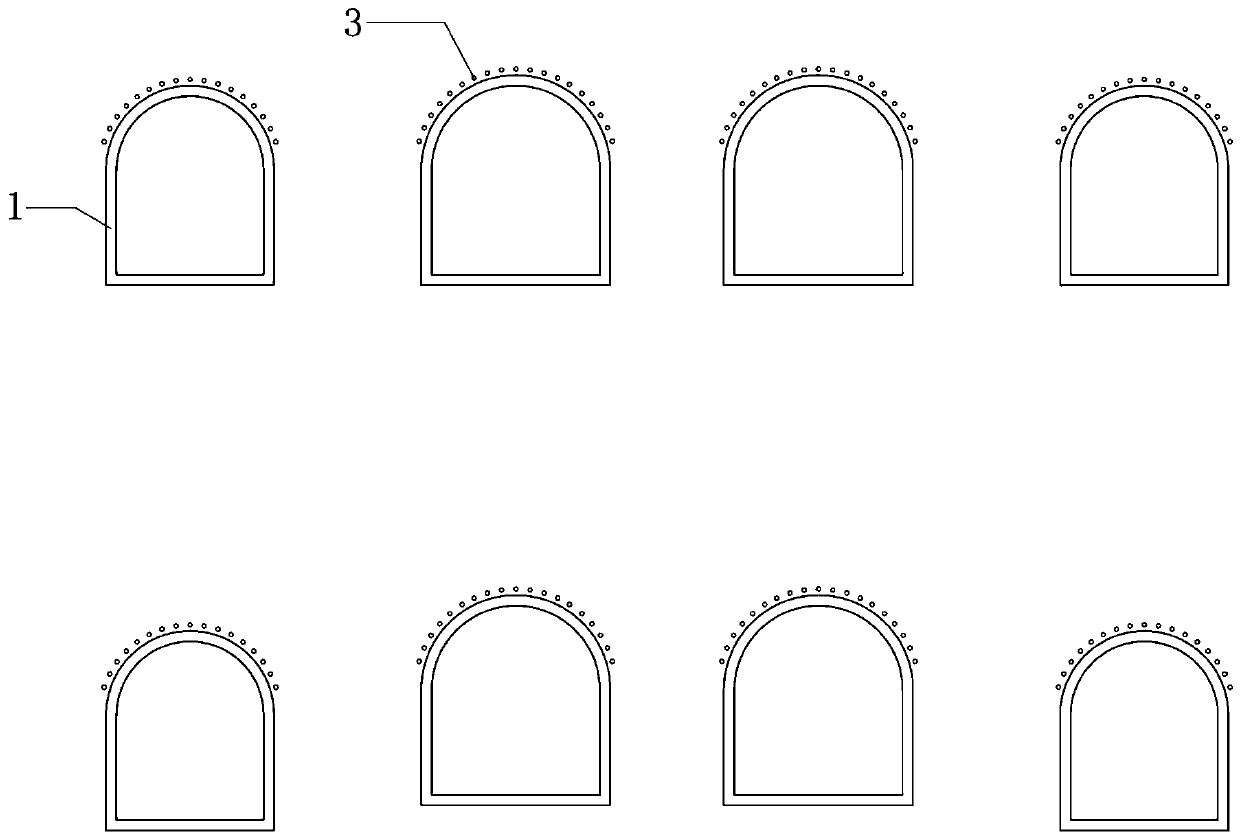

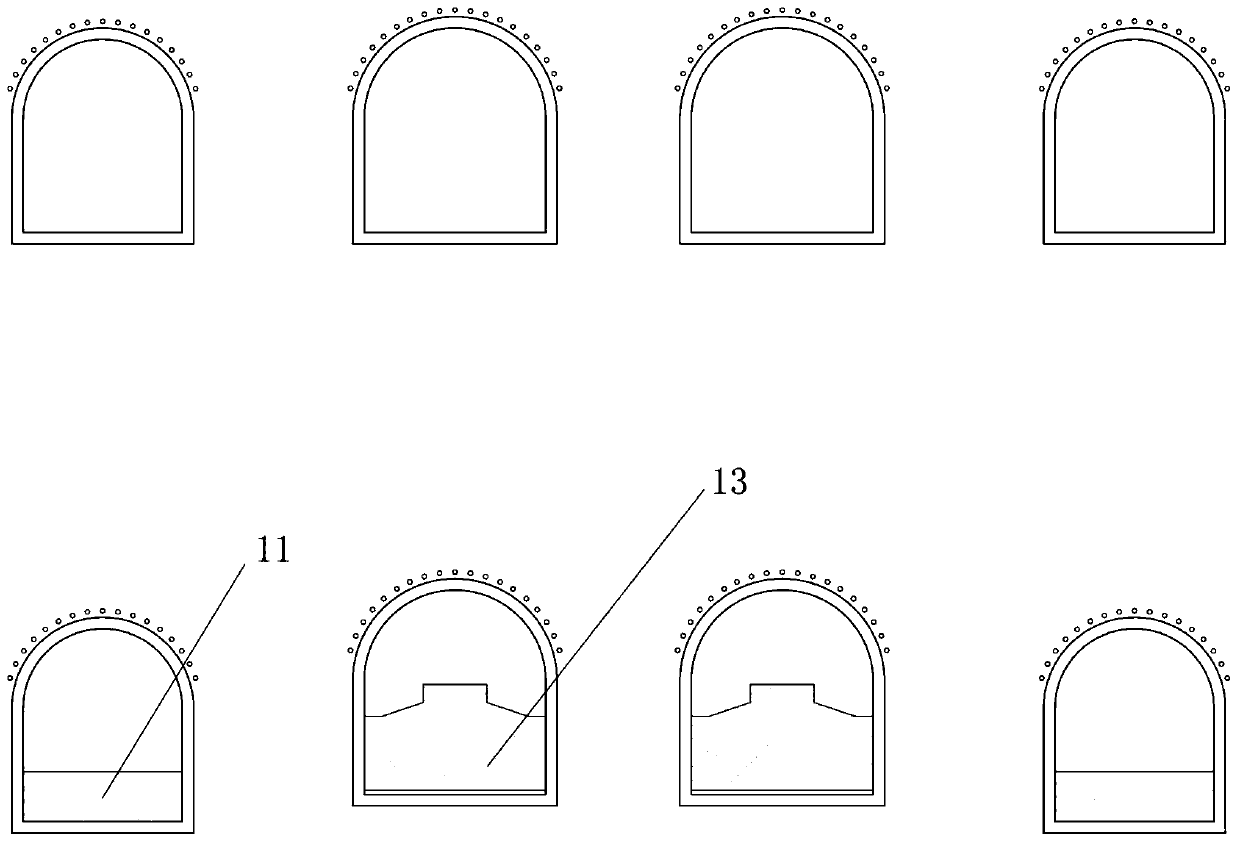

[0069] This embodiment provides a construction method for tunnel pillar underground excavation and reverse construction of underground structures, please refer to Figure 2-Figure 11 , this construction method carries out underground excavation within the radiation range below the house, and the rest is open excavation, which is used to construct the underground structure with underground excavation and reverse construction of the hole pillar in Embodiment 1, including the steps:

[0070] Step 1: See figure 2 The upper pilot tunnel and the lower pilot tunnel are excavated by the cross passage; the pilot tunnels on both sides are excavated first, and then the central pilot tunnel is excavated; the lower pilot tunnel is excavated first, and then the upper pilot tunnel is excavated. During construction, the initial Backfill grouting behind the branch in time, and carry out real-time monitoring and measurement, and seal the end of the pilot tunnel after it reaches the end; before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com