Detection method and detection device of rare earth elements in pore water

A detection method and technology of rare earth elements, applied in the field of detection methods and detection devices of rare earth elements in pore water, can solve the problems of poor accuracy of detection results, high loss of instruments, low recovery rate, etc., and achieve improved accuracy and elution rate Fast, avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The present embodiment provides a pretreatment method for rare earth element testing, which includes the following steps:

[0067] (1) Resin cleaning and filling

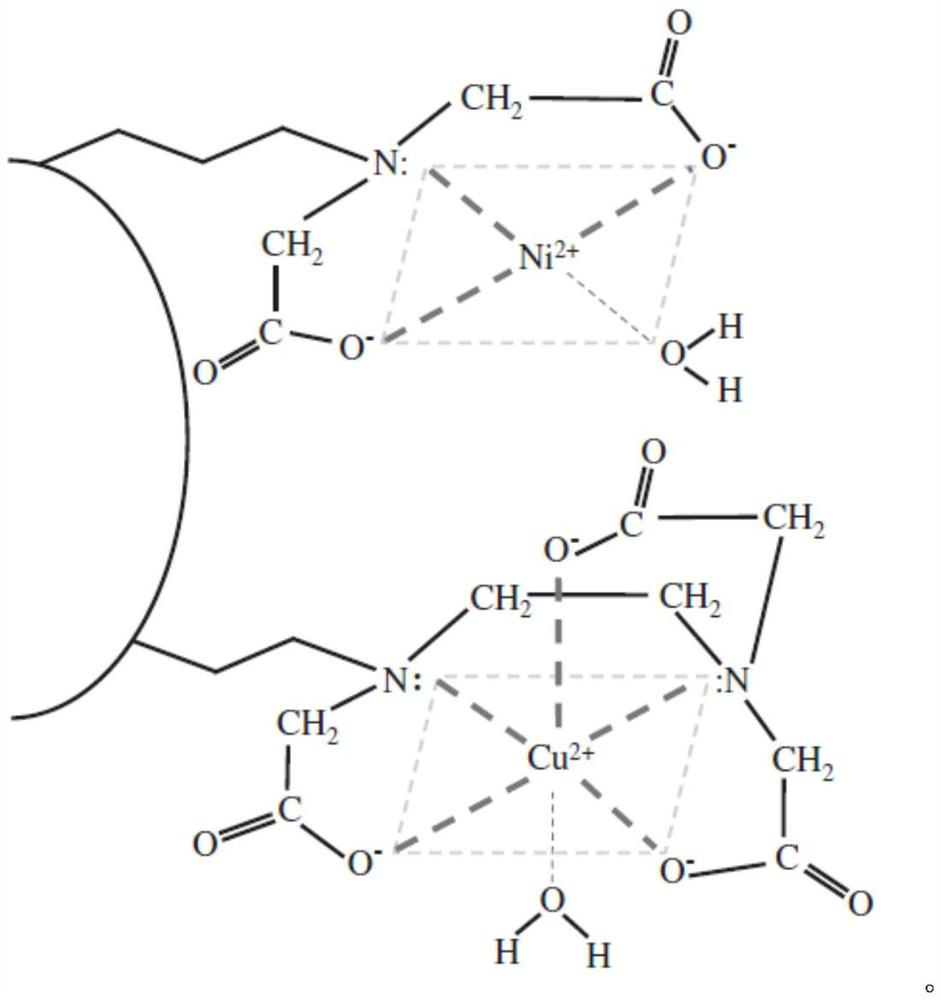

[0068] The NOBIAS chelate-PA1 resin was placed in a 50 mL centrifuge tube, and washed 4 times with 10 mL of methanol and 10 mL of deionized water, respectively. After cleaning, the resin was soaked in deionized water.

[0069] Use a pipette to suck up the mixed solution of deionized water soaked with resin. First, rely on gravity to slowly fill the resin tube (length 2cm) with the resin. When the filling is nearly full, let the deionized water flow through the resin driven by the peristaltic pump.

[0070] (2) Equipment assembly

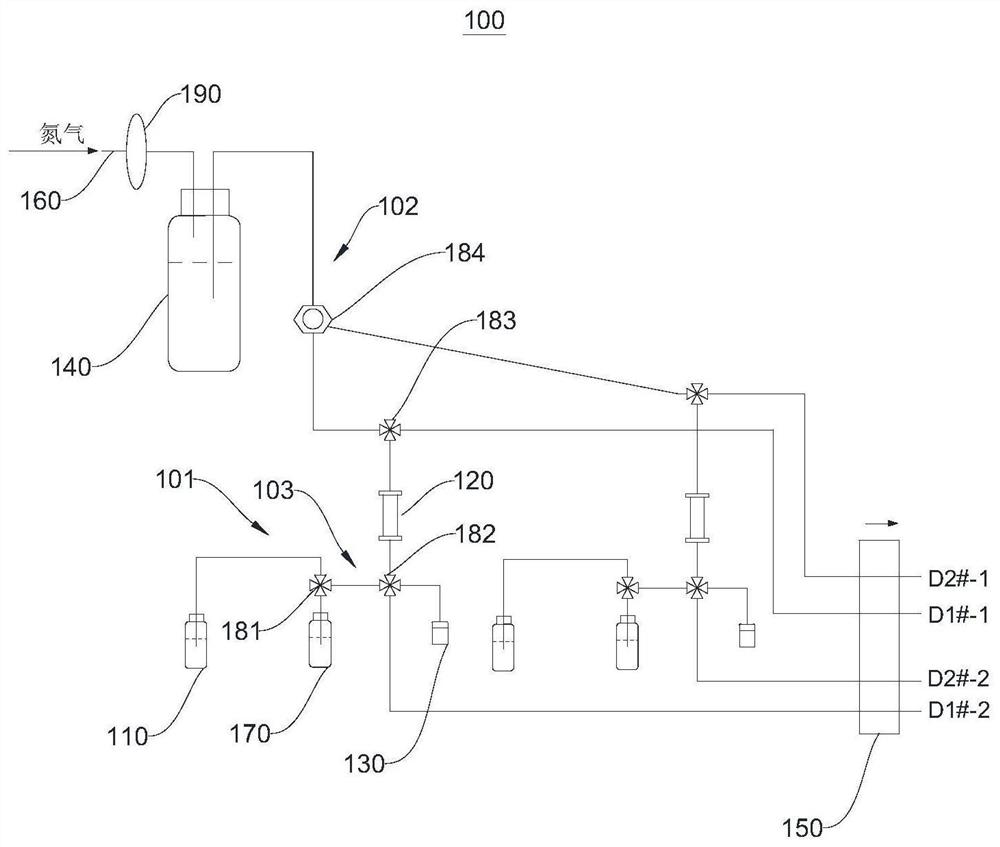

[0071] using as figure 1 A set of pretreatment devices shown in the enrichment and elution work, according to figure 1 The positional relationship in the connection processing device.

[0072] The resin in the equipment is cleaned before adsorption after equipment assembly. The...

Embodiment 2

[0086] The present embodiment provides a pretreatment method for rare earth element testing, which includes the following steps:

[0087] (1) Resin cleaning and filling

[0088] The NOBIAS chelate-PA1 resin was placed in a 50 mL centrifuge tube, and washed 4 times with 10 mL of methanol and 10 mL of deionized water, respectively. After cleaning, the resin was soaked in deionized water.

[0089] Use a pipette to suck up the mixed solution of deionized water soaked with resin. First, rely on gravity to slowly fill the resin tube (length 2cm) with the resin. When the filling is nearly full, let the deionized water flow through the resin driven by the peristaltic pump.

[0090] (2) Equipment assembly

[0091] using as figure 1 A set of pretreatment devices shown in the enrichment and elution work, according to figure 1 The positional relationship in the connection processing device.

[0092] The resin in the equipment is cleaned before adsorption after equipment assembly. The...

Embodiment 3

[0103] The present embodiment provides a pretreatment method for rare earth element testing, which includes the following steps:

[0104] (1) Resin cleaning and filling

[0105] The NOBIAS chelate-PA1 resin was placed in a 50 mL centrifuge tube, and washed 4 times with 10 mL of methanol and 10 mL of deionized water, respectively. After cleaning, the resin was soaked in deionized water.

[0106] Use a pipette to suck up the mixed solution of deionized water soaked with resin. First, rely on gravity to slowly fill the resin tube (length 2cm) with the resin. When the filling is nearly full, let the deionized water flow through the resin driven by the peristaltic pump.

[0107] (2) Equipment assembly

[0108] using as figure 1 A set of pretreatment devices shown in the enrichment and elution work, according to figure 1 The positional relationship in the connection processing device.

[0109] The resin in the equipment is cleaned before adsorption after equipment assembly. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap