Fumigating equipment as well as application method and application thereof

A kind of equipment and fumigation technology, applied in the fields of application, tobacco, and tobacco preparation, can solve problems such as steel defects, smoke and mildew in curing rooms, and achieve the effects of reducing losses, avoiding mold, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The specific working process of the tobacco leaf intensive curing barn is as follows:

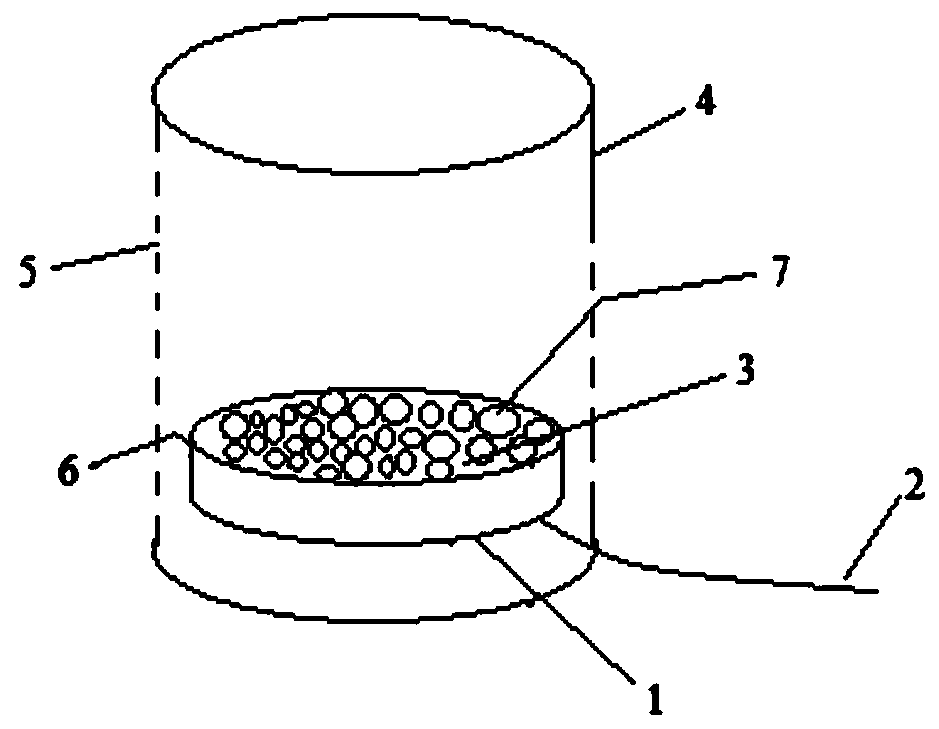

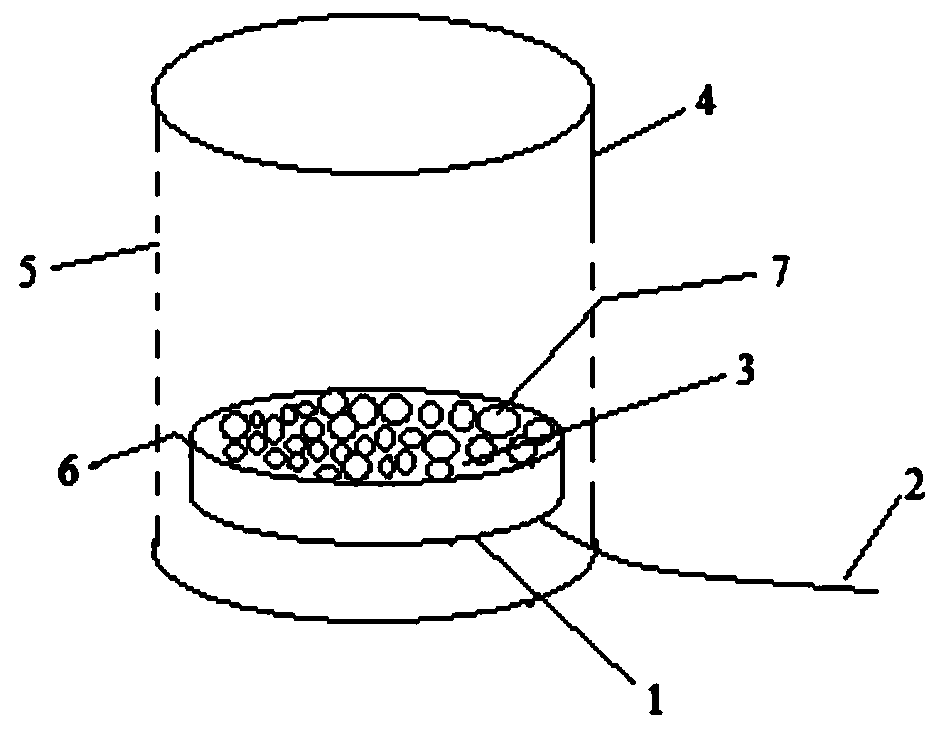

[0032] After the tobacco leaves were put on the kang, clean the tobacco room in the barn, and then apply the present invention figure 1 Put the fumigation equipment shown on the ground in the fumigation chamber, lead the external wires out of the fumigation chamber, fill the fumigation material trichloroisocyanuric acid in the tray, close the door of the curing room, start the fumigation equipment, and do not use it within 12 hours. Open the smoke door of the barn, the left and right dust removal doors and the inspection door of the circulation fan, and do not look at the smoke at the dehumidification window.

[0033] Embodiment 1 of the present invention achieves disinfection without dead ends by using fumigation equipment, which is easy to control the unit dosage, the time is short, and the hazards are easy to control. In the prior art, manual spraying of medicaments cannot achiev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com