Preparation method of pipettor for transferring trace liquid drop losslessly based on pyroelectric effect

A pyroelectric, lossless technology, applied in the field of pipettes, can solve the problems of inability to discharge trace solutions, inaccurate pipetting accuracy, loss of solution, etc., to avoid inaccurate detection results, simple preparation method and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

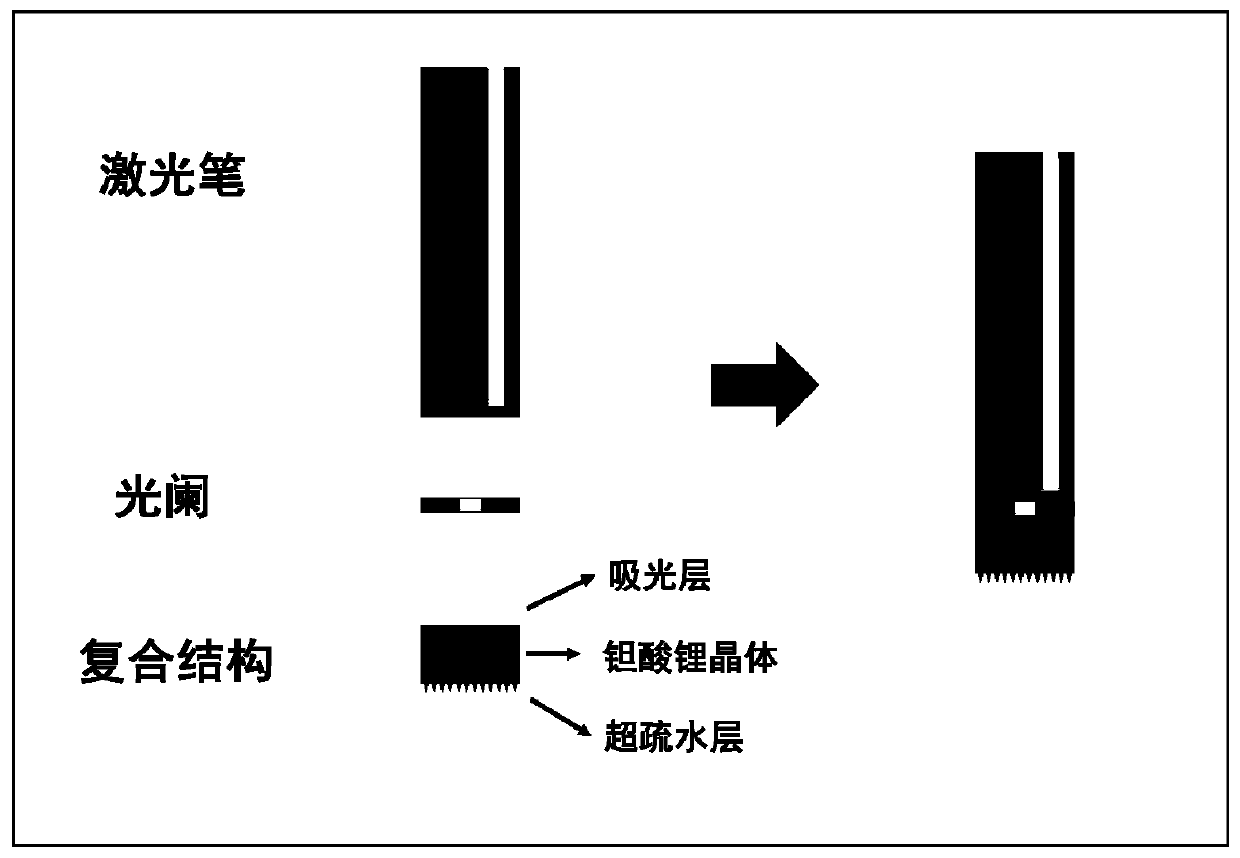

[0033] A method for preparing a pipette for pipetting micro-droplets without loss based on the pyroelectric effect, comprising the following steps:

[0034] 1) Take a piece with a size of 5*5*0.5mm 3 For a clean lithium tantalate wafer, apply oily black ink evenly on the lower surface to prepare a layer of light-absorbing layer;

[0035] 2) preparing a super-hydrophobic layer with a uniform thickness on the upper surface of the lithium tantalate wafer in step 1), to obtain a composite material;

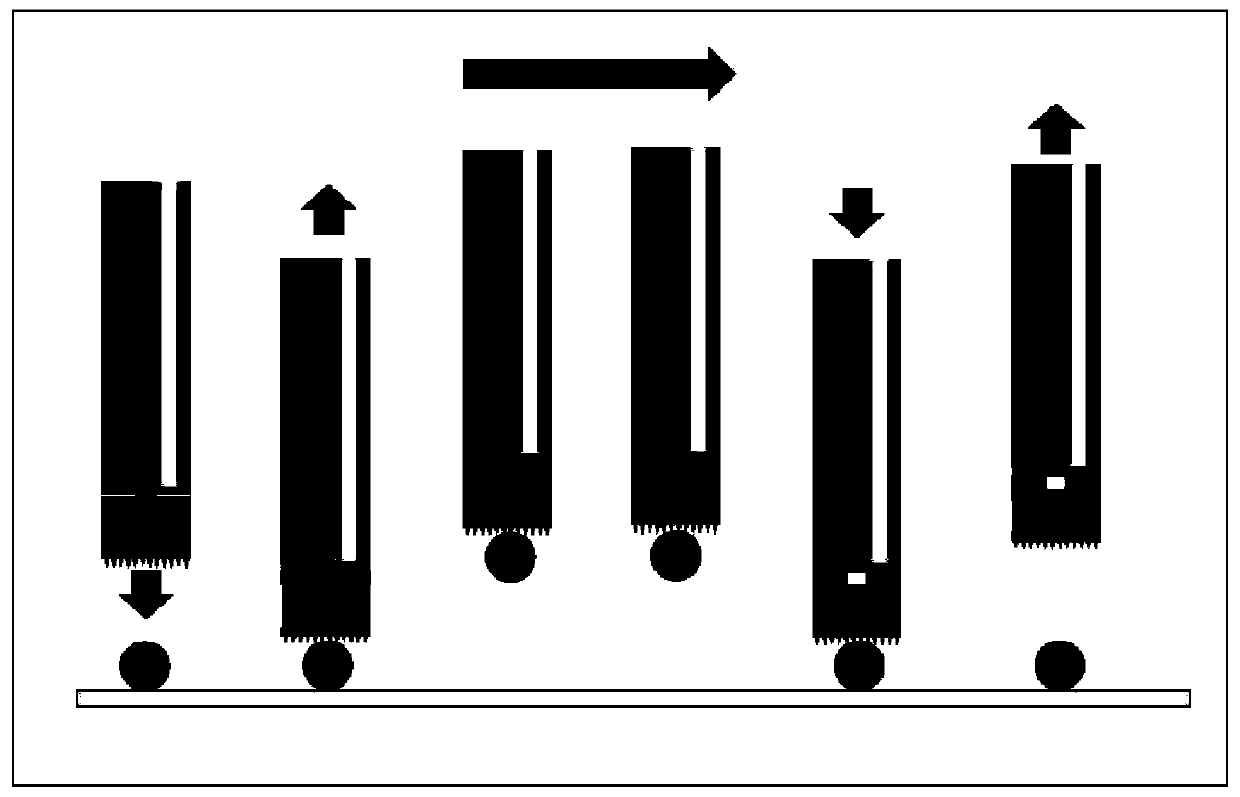

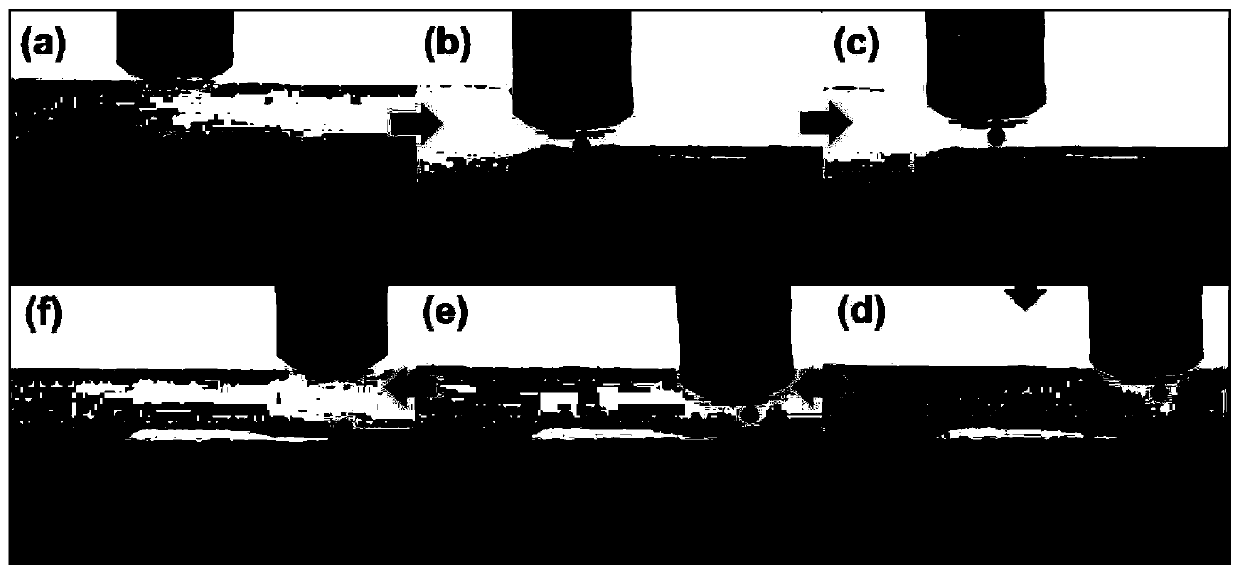

[0036] 3) Use glue to stick a metal sheet with a small hole on the light outlet of the infrared laser pointer with a wavelength of 671nm as a diaphragm, then align the light-absorbing layer of the composite material with the metal sheet with a small hole, and place the composite material Glue is used to fix the lower surface of the metal sheet with small holes, and the superhydrophobic layer faces outward to obtain a pipette. The specific preparation process is as follows: figure 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap