Automatic and continuous filling system of blood sampling tubes

An automatic and filling technology, applied in sorting and other directions, can solve the problems of test tube wear and scratch, failure to automatically detect test tube defective products, test tube defective products, etc., to ensure quality, achieve rapid removal, and reduce stuck tubes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

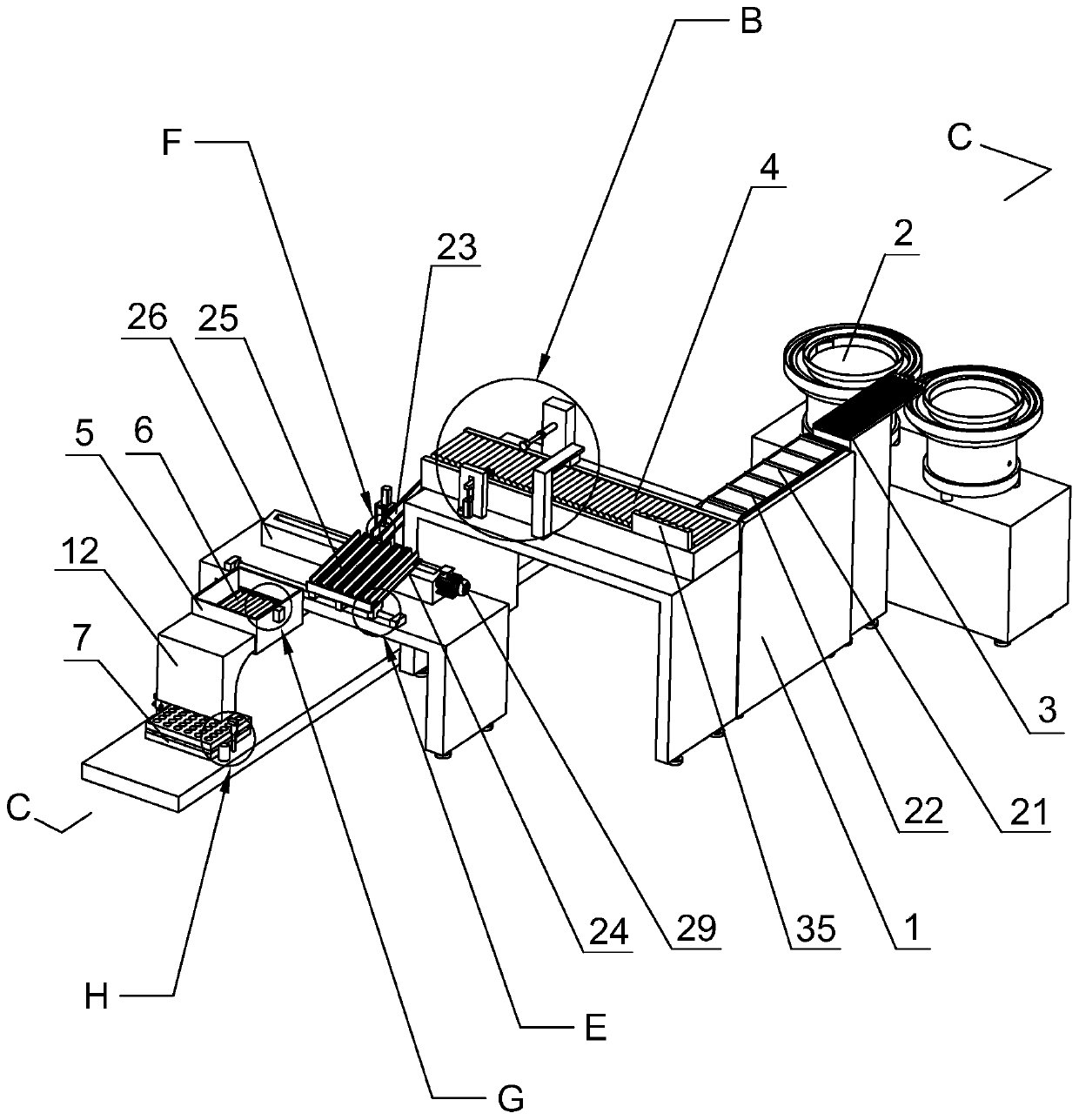

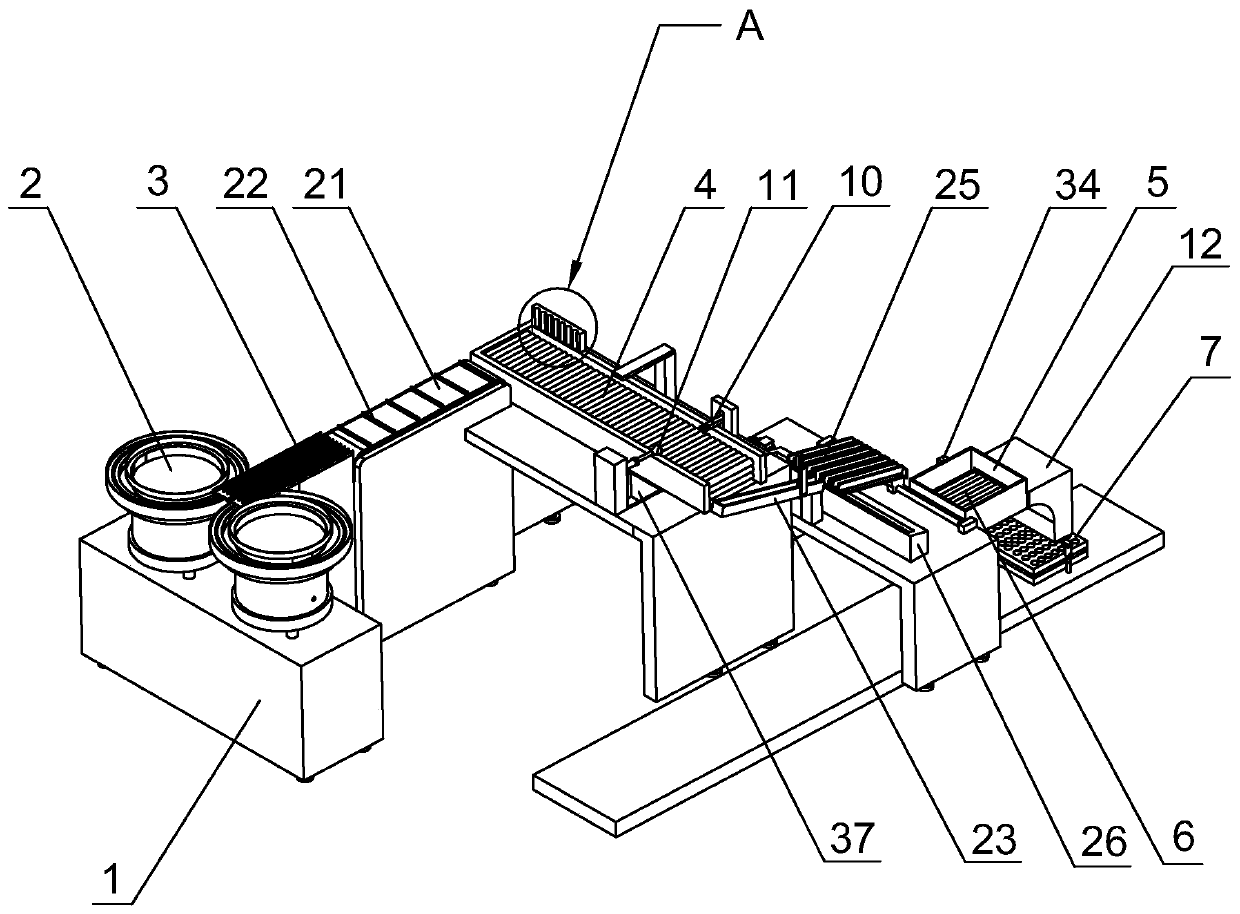

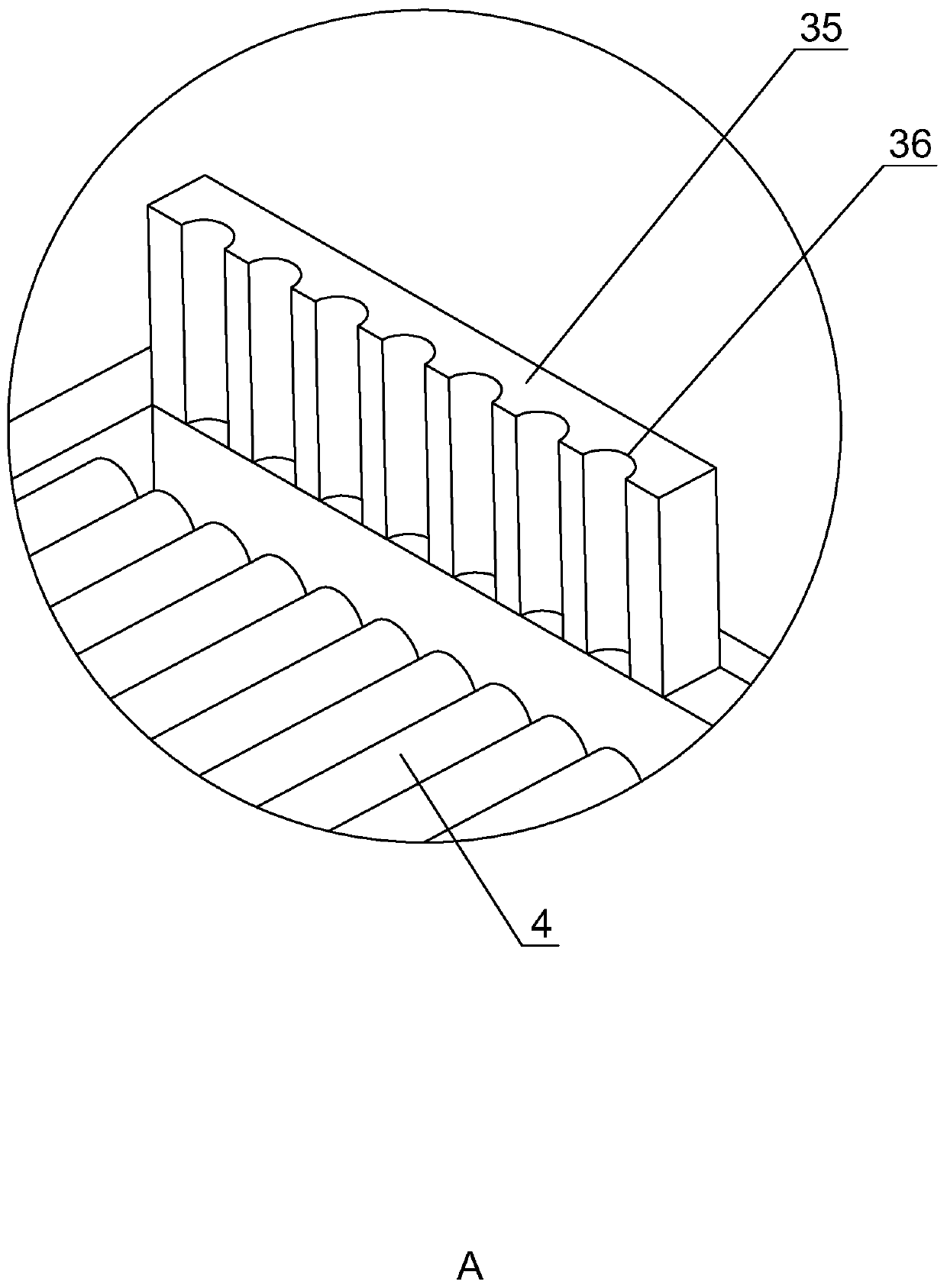

[0043] refer to figure 1 , is a kind of test tube automatic continuous filling system disclosed by the present invention, and the present invention is realized through the following technical solutions: including body 1, referring to figure 1 and figure 2 The body 1 is provided with a vibrating plate 2, a conduit channel 3, a roller table 4, a collection box 5, and a mold frame 7 in sequence along the test tube conveying direction; the vibrating plate 2, the conduit channel 3, and the roller table 4 are used to automatically guide the test tubes in order and Orientation is transferred to the collection box 5. The bottom of the collection box 5 is provided with a vibrating tray 6. A motor that drives the vibrating tray 6 to vibrate is fixed on the body 1. The side of the vibrating tray 6 away from the motor is provided with a plurality of side-by-side placem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com