Plate/strip spray back face powder floating sweeper and electrostatic powder spraying device

A technology of cleaning device and strip, applied in spraying device, spray booth, cleaning method and utensils, etc., can solve the problems of unqualified strip, deviation, deviation of strip center line, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

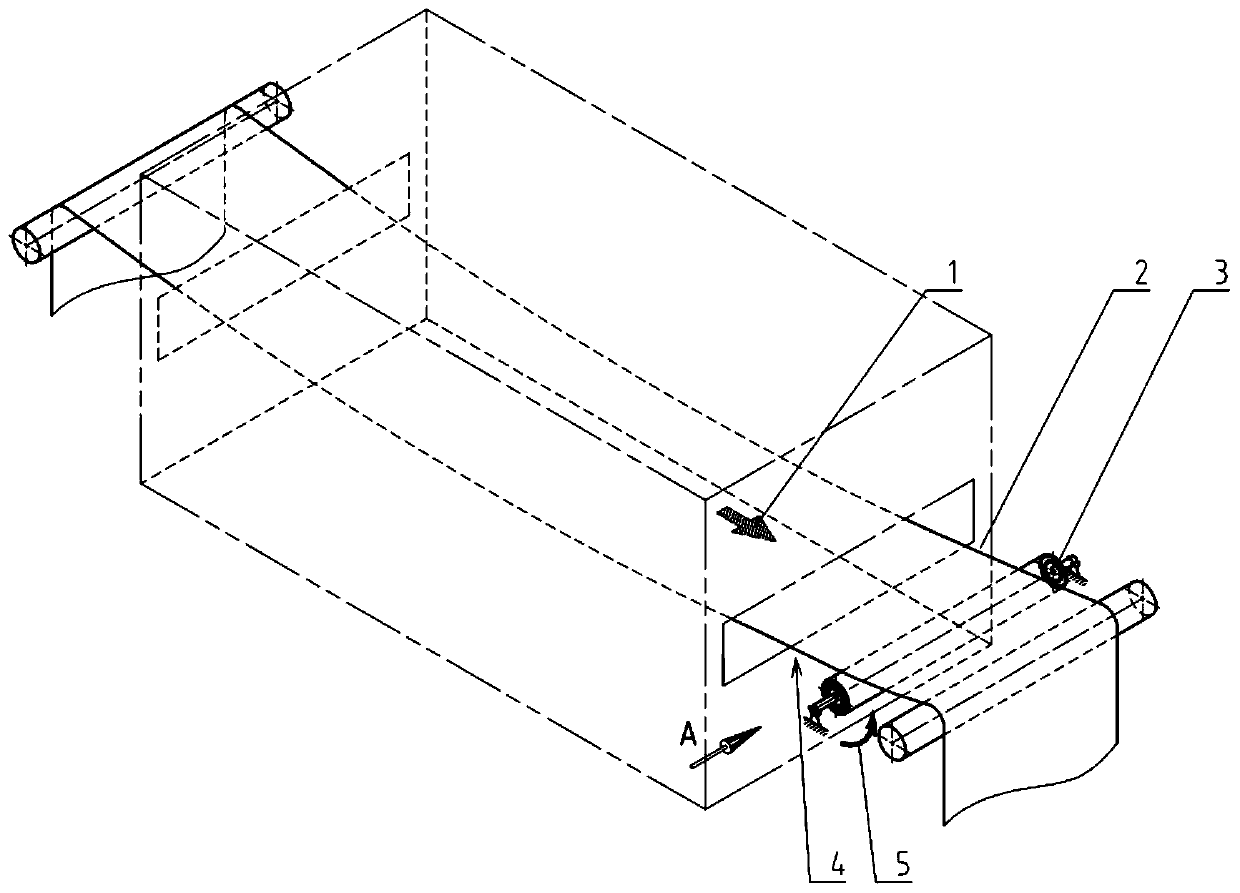

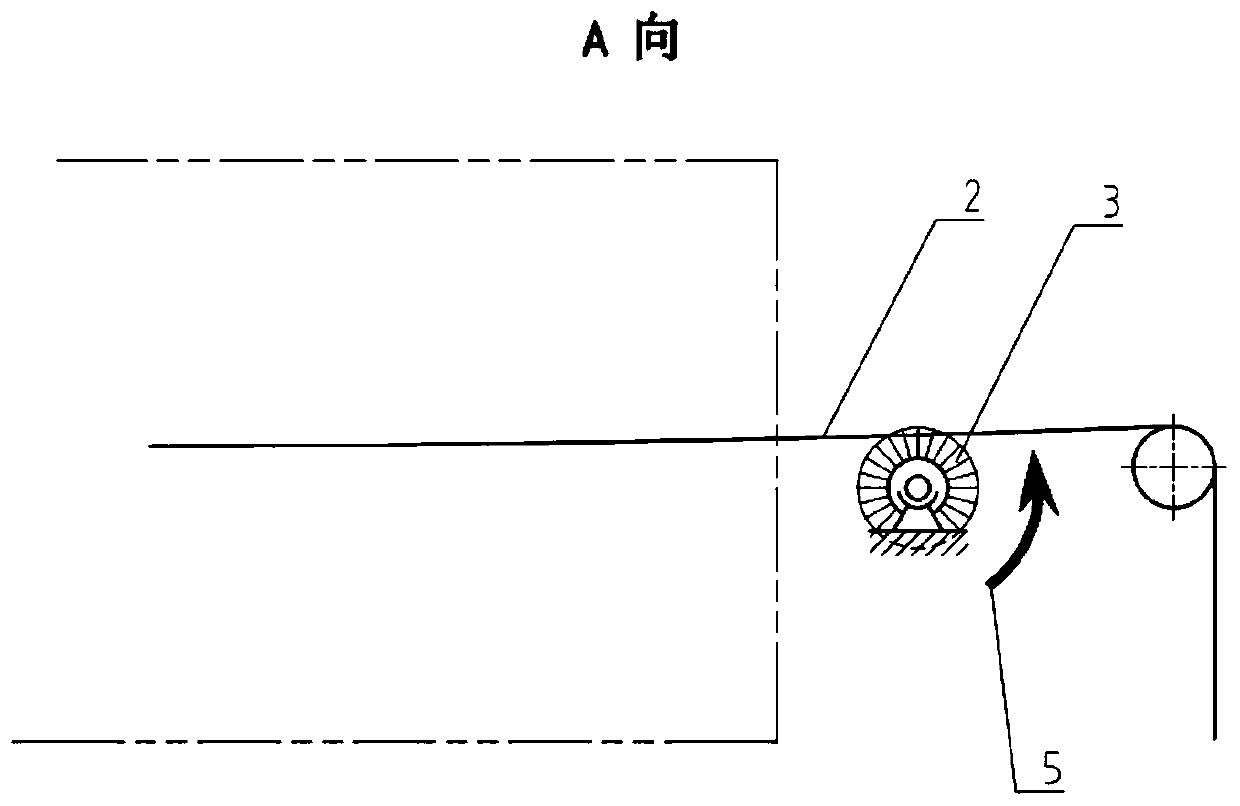

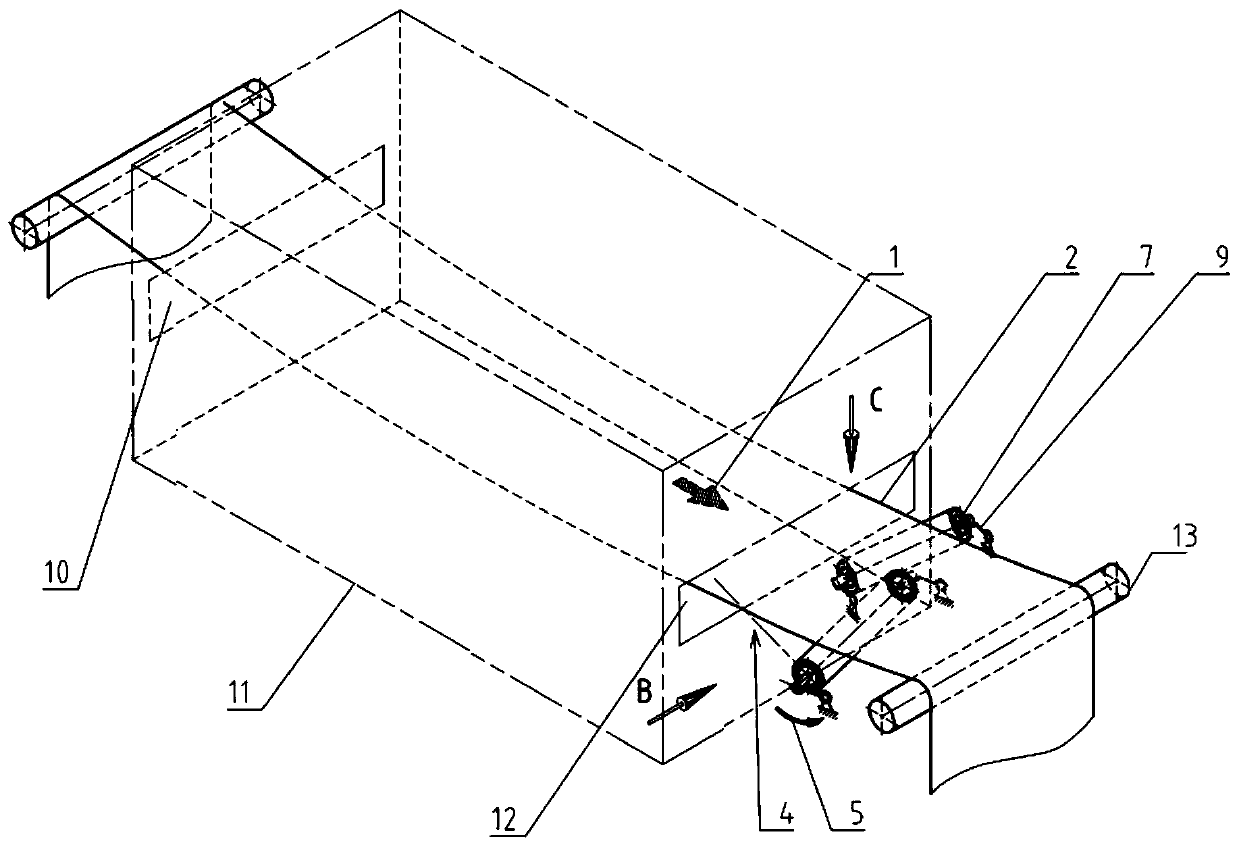

[0039] The overall inventive idea of the present invention is: the rotating axis of the roller brush is passed through the floating follow-up mechanism so that the roller brush always contacts the back of the strip when the strip is lifted and floated, so that when the roller brush rotates, the bristles will not be separated from the strip due to the floating of the strip. The back of the strip; the strip floats up and then falls back down, the roller brush bristles still touch the back of the strip all the time, ensuring that the roller brush can always touch the back of the strip and clean it, ensuring the performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com