Turning connection device based on high-precision detecting instrument

A testing instrument and switching device technology, applied in the field of switching devices based on high-precision testing instruments, can solve the problems of unbalanced friction torque between the rotating shaft and the switching piece, uneven bearing capacity of the switching piece, measurement error, etc. Reduces uneven load bearing capacity, avoids deformation behavior and torsional vibrations, reduces the effect of friction torque imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

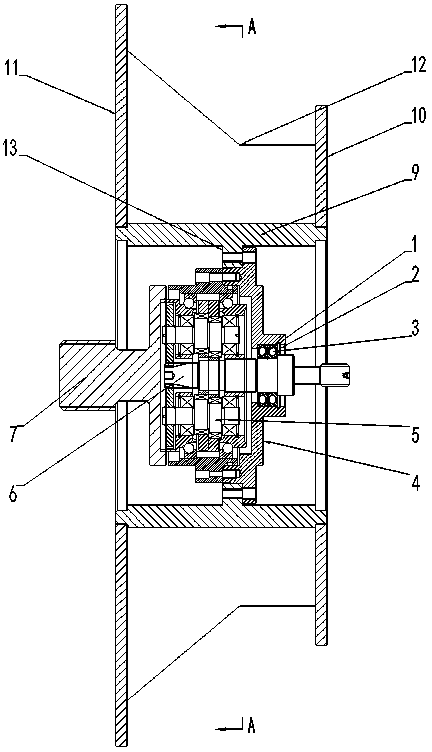

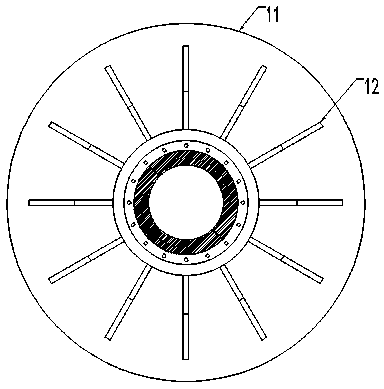

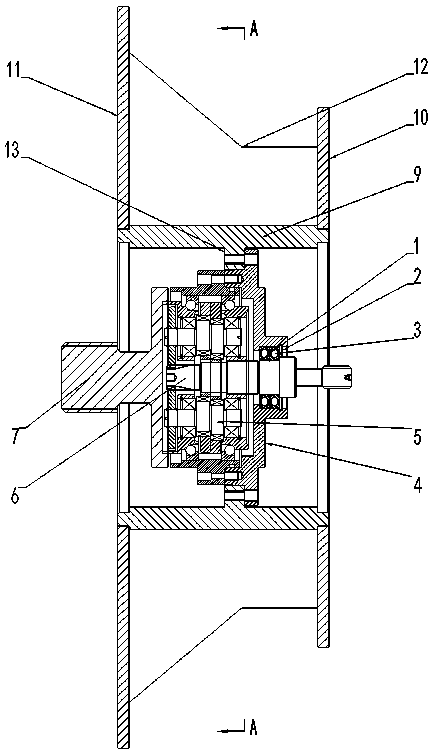

[0023] Examples such as Figure 1-2 As shown, an adapter device based on a high-precision detection instrument includes a cylinder 9, the upper and lower ends of the cylinder 9 are respectively fixedly connected to the detection equipment through a support unit, a reducer 5 is arranged inside the cylinder 9, and the cylinder 9 9 is provided with a connection unit for easy connection with the component to be tested.

[0024] One end of the reducer 5 is provided with an input shaft 6 , which is in drive connection with the testing equipment, and the other end is provided with an output flange 7 .

[0025] The connecting unit includes an end connecting piece for fixed connection with one end of the reducer 5 , and the end connecting piece is a reducer mounting seat 4 with a stepped longitudinal section.

[0026] The reducer mounting base 4 is coaxially assembled with the input shaft 6, and the position on the reducer mounting base 4 corresponding to the housing of the reducer 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com