Self-locking type rigid-soft coupling mechanical gripper

A mechanical gripper and self-locking technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of insufficient rigidity, limited grasping capacity and carrying capacity, poor stability, etc., to ensure flexibility and softness, and lift loads Capability and stability, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

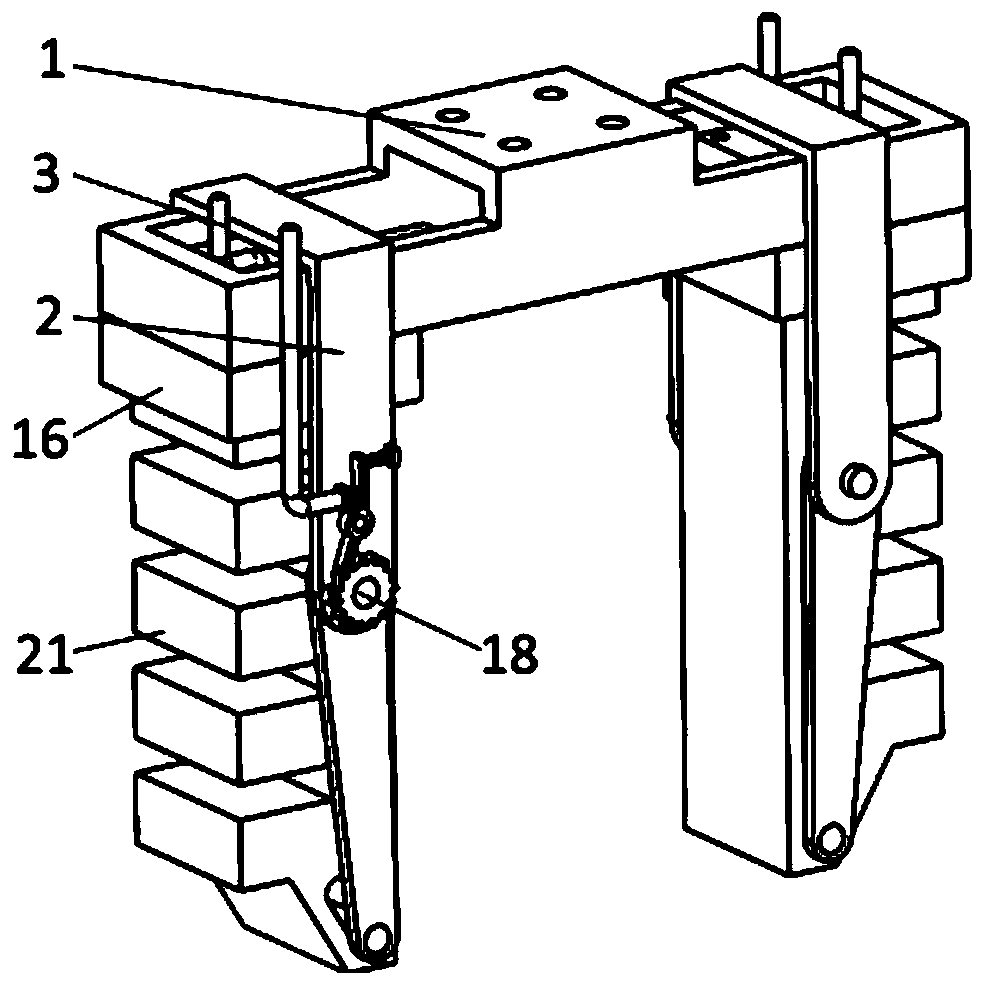

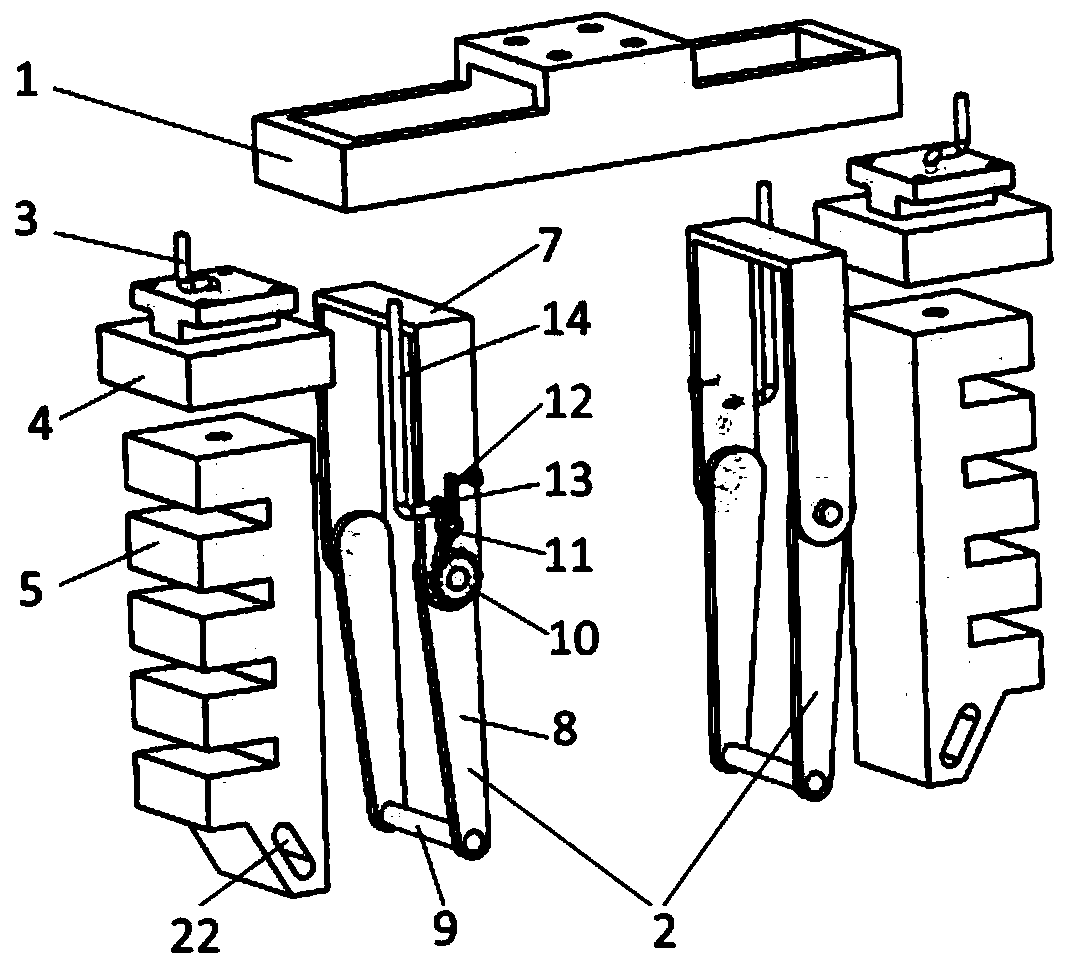

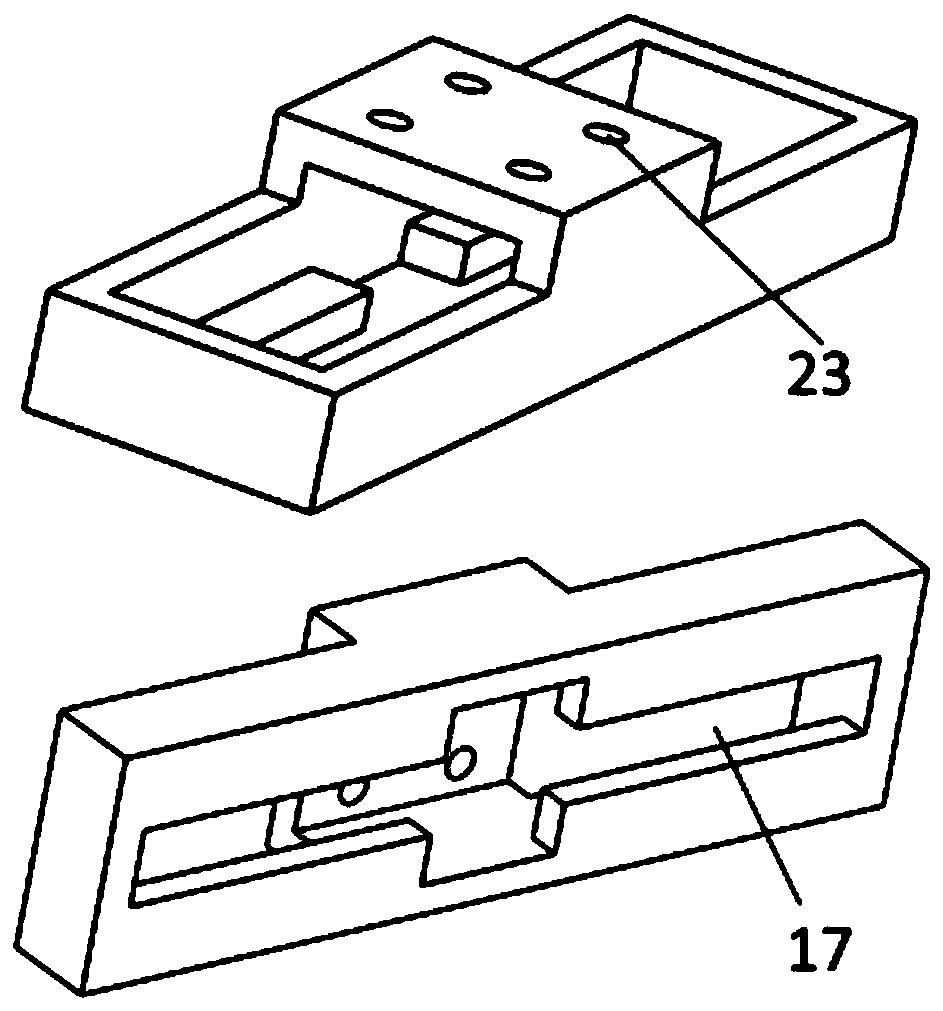

[0021] like figure 1 As shown, a self-locking rigid-soft coupling mechanical gripper involved in this embodiment includes: an adjustable mounting seat 1 and two sets of self-locking exoskeletons 2 centrally symmetrically arranged at both ends of the adjustable mounting seat 1, fingers Assembly 16, wherein: the finger assembly 16 is arranged under the adjustable mounting seat 1, and the self-locking exoskeleton 2 is placed on the finger assembly 16 and connects the adjustable mounting seat 1 and the finger assembly 16 as a whole.

[0022] The self-locking exoskeleton 2 includes: a fixed upper frame 7, a movable lower limb 8, a pin rod 9 and a self-locking mechanism 18, wherein: the fixed upper frame 7 is arranged on the adjustable mounting seat 1 and the finger assembly 16, and the movable lower limb 8 One end is movably connected to the fixed upper frame 7 through the rotating shaft 19 , and the other end is connected to the finger assembly 16 through the pin rod 9 .

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com