Logistical safe unloading device

A safety and logistics technology, applied in the directions of loading/unloading, transportation and packaging, it can solve the problems of vibration and shaking of goods, adverse effects of goods, etc., and achieve the effect of stable sliding and stable deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

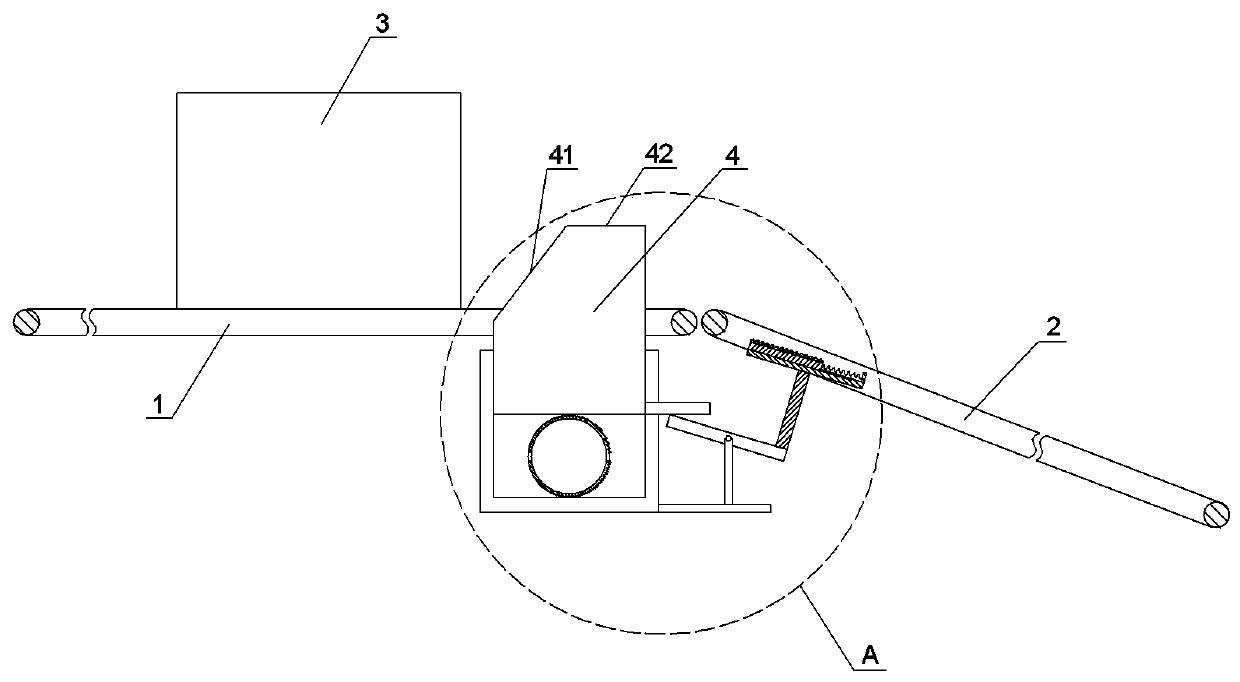

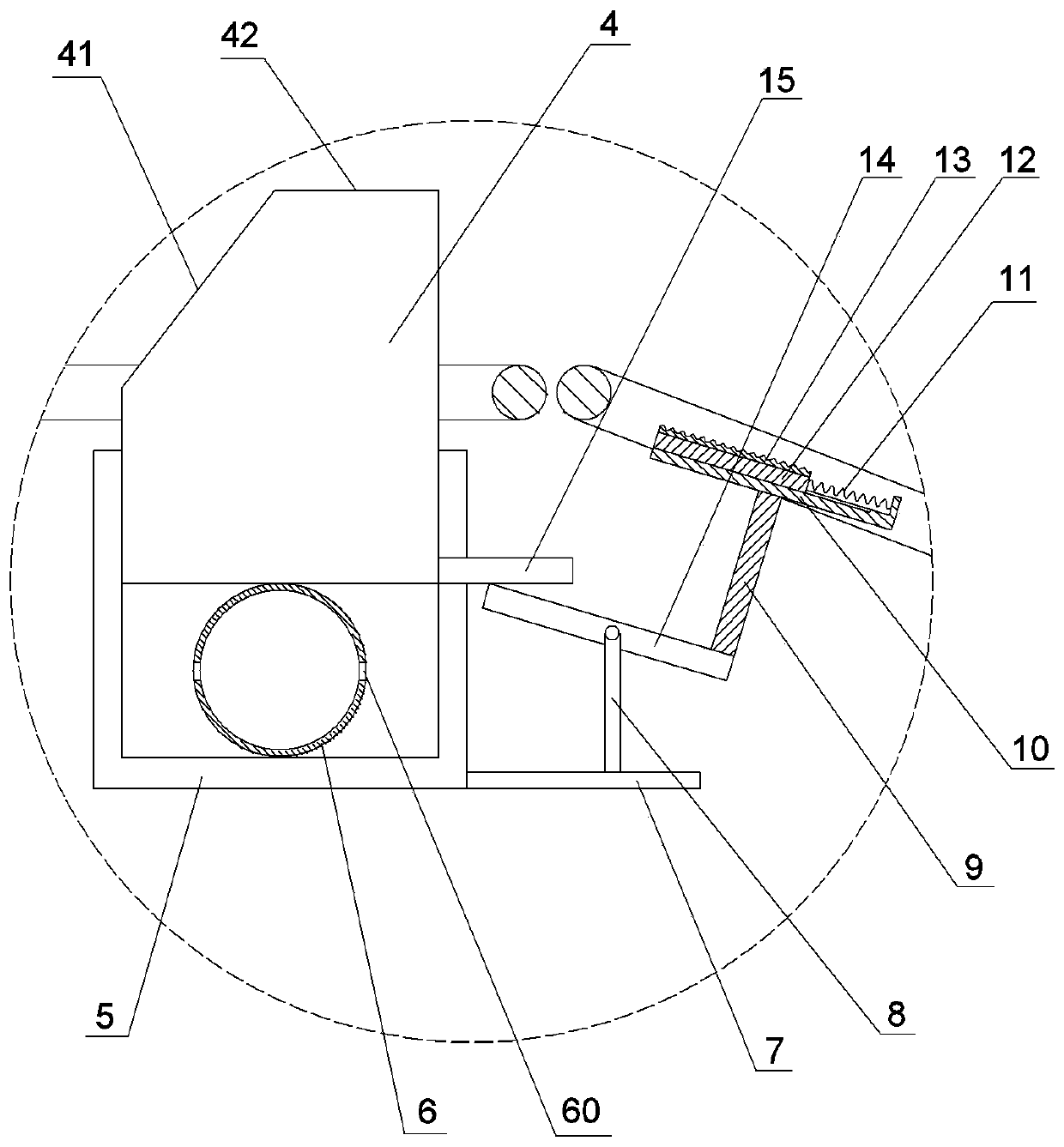

[0023] The following is further described in detail through specific implementation methods:

[0024] The reference signs in the accompanying drawings include: straight section 1, inclined section 2, cargo 3, drive block 4, wedge surface 41, horizontal surface 42, chute 5, elastic ball 6, air hole 60, fixed seat 7, pillar 8 , Support rod 9, fixed support portion 10, spring 11, sliding support portion 12, rubber anti-skid layer 13, lever 14, pressing plate 15.

[0025] like figure 1 and figure 2 As shown, a logistics safety unloading device in this embodiment includes a discharge conveyor belt, the discharge conveyor belt includes a straight section 1 and an inclined section 2, and the discharge end of the straight section 1 is aligned with the high end of the inclined section 2 . The straight section 1 includes two conveyor rollers and two conveyor belts, the conveyor belts are parallel to each other, and the two ends of the conveyor belts are respectively sleeved on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com