Gear shifting hand rocker

A hand crank and shifting mechanism technology, which is applied in the field of hand cranks, can solve the problems of large volume, unstable shifting, and high cost of the hand crank, and achieve the effects of small overall size, stable shifting, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

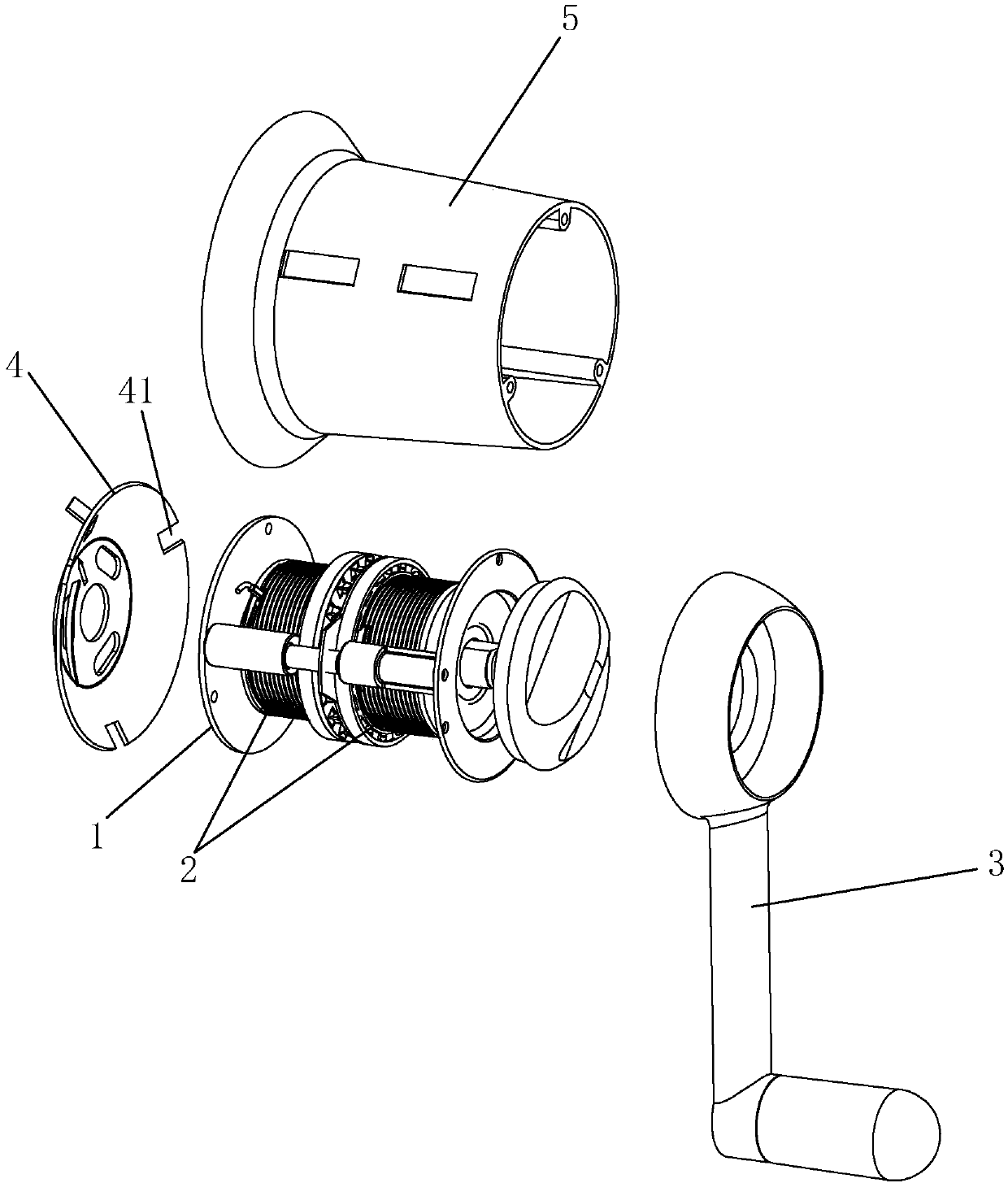

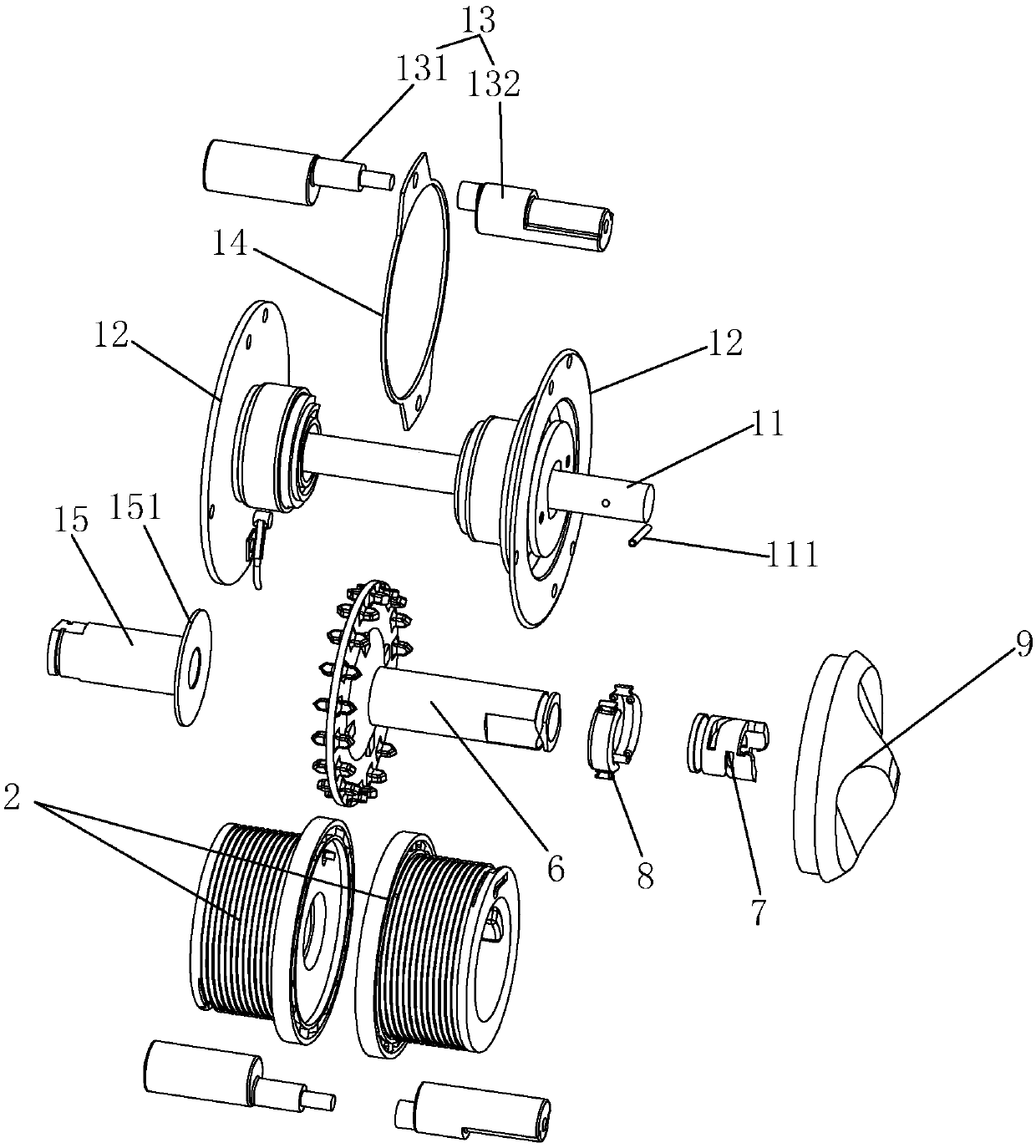

[0034] Examples, see Figure 1-Figure 13 As shown, a shift hand crank of the present invention includes a fixed body 1, two winding wheels 2, a handle 3 and a shift mechanism, and the shift mechanism includes a hollow push-pull part 6, and the push-pull part 6 is provided with The clip 61; the fixed body 1 has a support shaft 11, the push-pull part 6 is rotatably sleeved on the support shaft 11, and is connected to the handle 3; the two winding wheels 2 are respectively rotatably sleeved on the support shaft 11 or The push-pull part 6 or the sleeve provided on the support shaft 11;

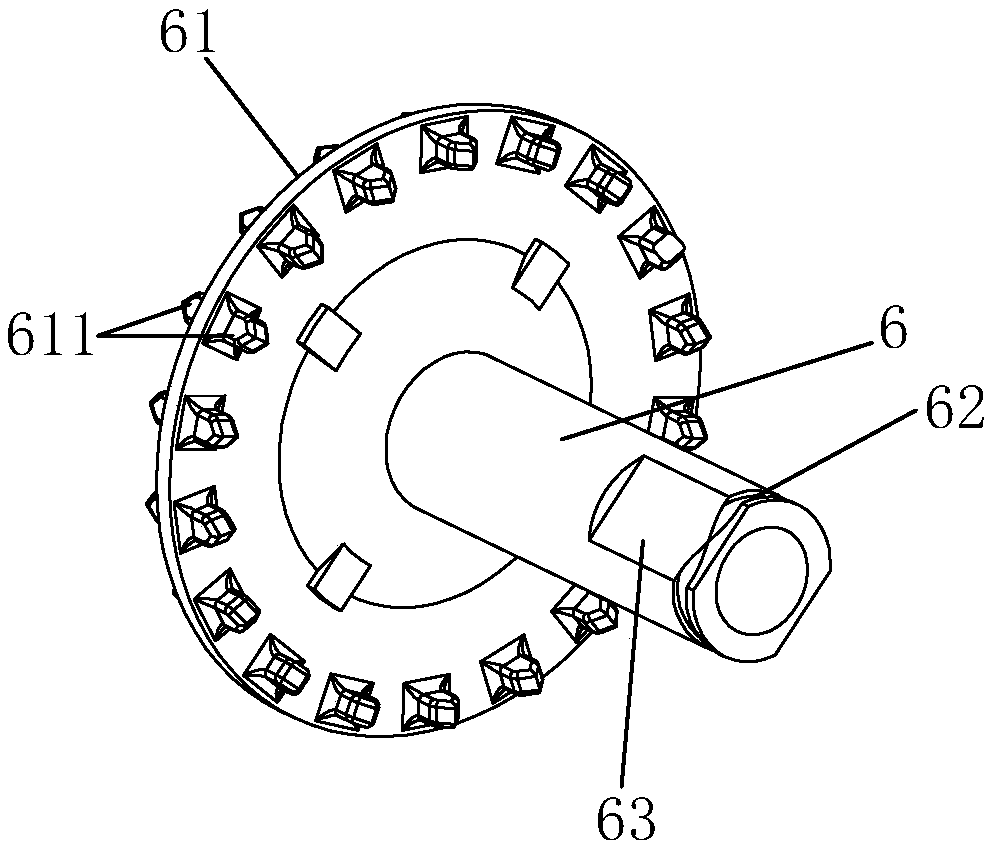

[0035] In this embodiment, the clamping member 61 fits between the two reels 2, and the clamping member 61 is specifically a disc structure, and the two ends of the clamping member 61 are respectively distributed with several protrusions along the circumferential direction. Teeth 611 , the opposite inner end surfaces of the two reels 2 are respectively distributed along the circumferential direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com