Self-locking rope winch

A self-locking and rope technology, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of high labor cost, low labor efficiency, short service life, etc., and achieve high safety performance, high transportation efficiency and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

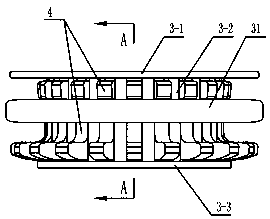

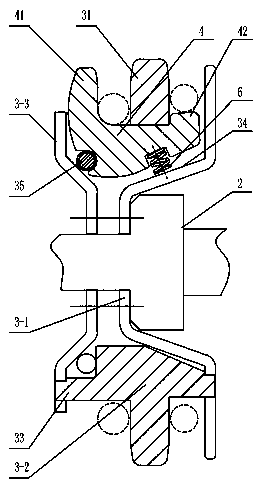

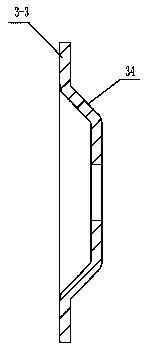

[0024] Such as figure 1 As shown, the present invention provides a self-locking rope winch, which includes a drive wheel body 3 that can rotate under the drive of the power device, and the drive wheel body 3 is connected with multiple rings that can swing and are distributed along the interval ring of the drive wheel body. A swing briquetting block 4, one end of the oscillating briquetting block 4 is provided with a pressing arm 41, the other end is provided with a driving part 42, and the driving wheel body 3 is provided with a radially outward extension and is located between the pressing arm and the driving part. The ring shoulder 31 of the pressing arm 41 and the ring shoulder 31 form a ring groove for the rope to pass through. Ring protruding shoulder 31, the return mechanism that drives the swing pressure block to return is housed on the driving wheel body 3, refer to figure 1 , that is to say, when an external force is applied to the driving part, when the driving part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com