High-temperature-resistant ferrochrome alloy for heat-resistant cushion block of steel rolling heating furnace and preparation method thereof

A ferrochrome alloy, high temperature resistant technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of high temperature creep, service life of only 1 year, poor cooling effect of heat-resistant pads, etc., to alleviate oxidation, The effect of prolonging the service life and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The second aspect of the present invention provides a method for preparing the above-mentioned high-temperature-resistant ferrochrome alloy, the steps comprising:

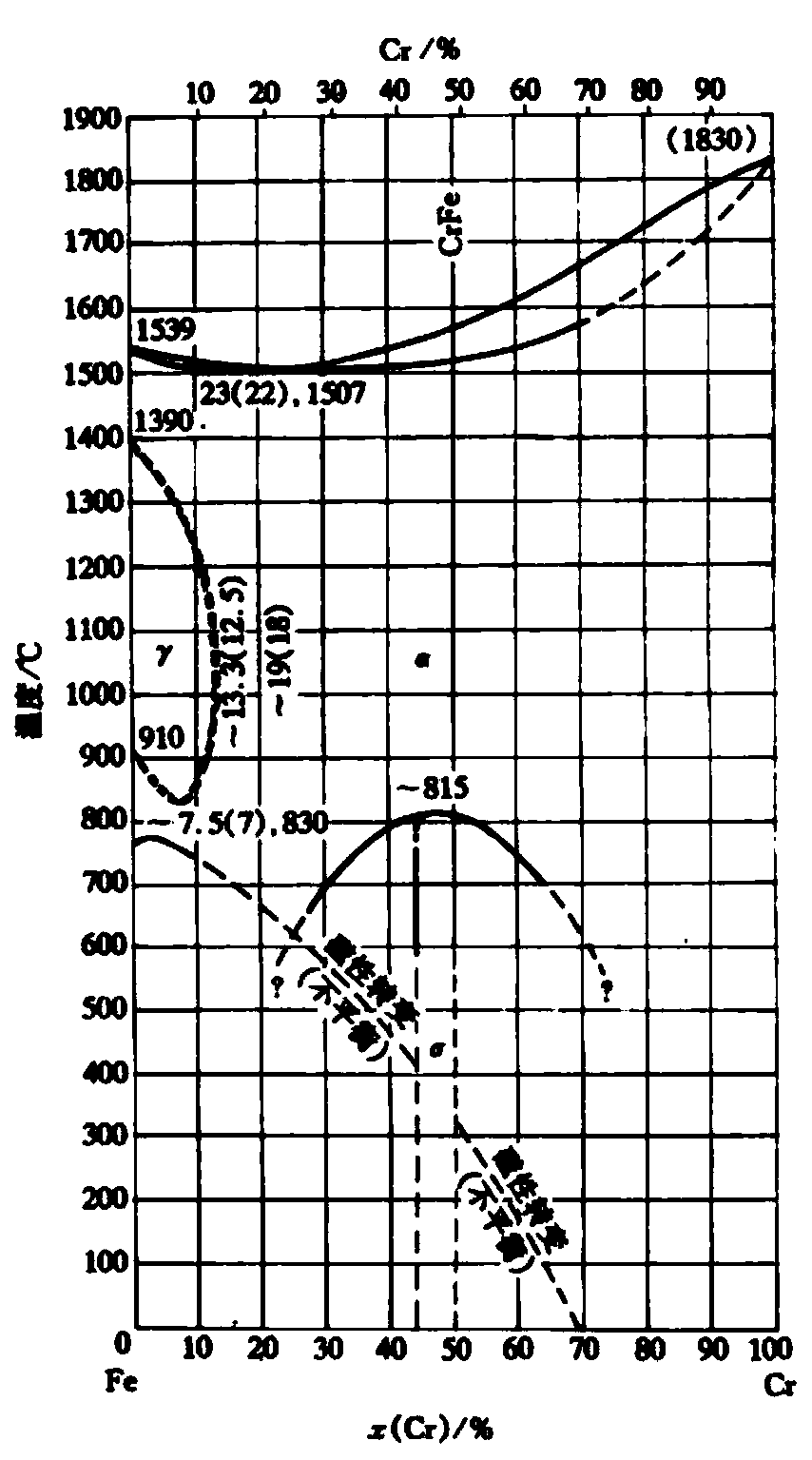

[0032] S1. According to the proportion of high-temperature-resistant ferrochrome alloy, first mix chromium and iron, and melt at 1650-1700°C to obtain ferrochrome alloy liquid;

[0033] S2, adding tungsten to the ferrochrome liquid, mixing evenly to obtain master alloy;

[0034] S3. Carry out vacuum smelting of the master alloy at 1800-1900° C., and cast it into shape by die casting method. The casting temperature is 1680-1720° C. to obtain a high-temperature-resistant ferrochrome alloy.

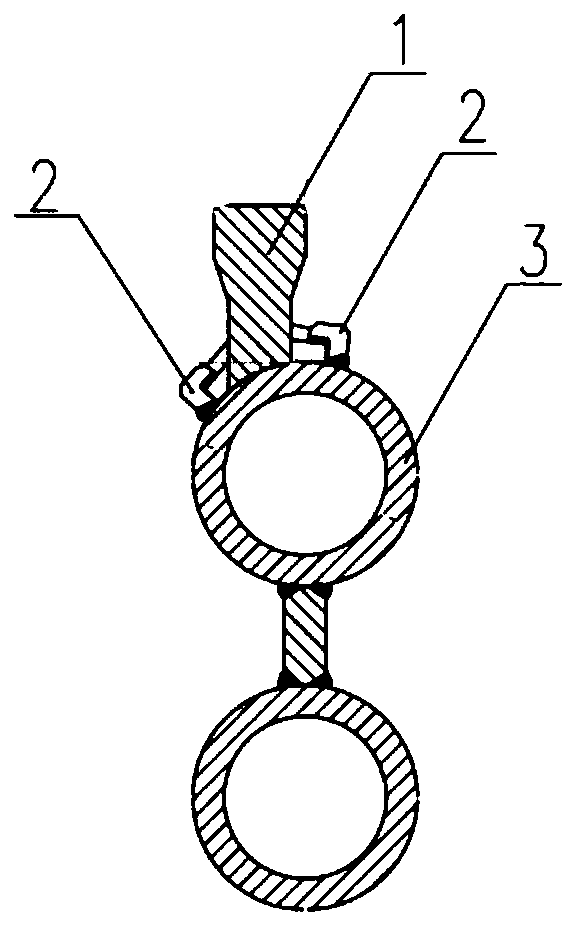

[0035] The third aspect of the present invention provides a heat-resistant pad for a steel rolling heating furnace. The high-temperature-resistant ferrochrome alloy prepared by the above preparation method is cleaned, finished, and inspected to obtain a heat-resistant pad for a steel rolling heating furnace with a thicknes...

Embodiment 1

[0037] This embodiment provides a high-temperature-resistant ferro-chrome alloy for a heat-resistant pad of a steel rolling heating furnace, and its chemical composition is shown in Table 1.

[0038] Table 1 Chemical composition of high temperature ferrochrome alloy

[0039] chromium iron tungsten other 85% 13% 1.9% 0.1%

[0040] The high-temperature-resistant ferrochromium alloy of the present invention adopts vacuum smelting and precision casting, and its main technological process is: process design→mold manufacturing→alloy melting→casting→cleaning and finishing→inspection→finished product.

[0041] The specific process is as follows:

[0042] Design process to prepare molds for precision casting with high temperature resistance. According to the proportion of high-temperature-resistant ferrochrome alloy, first mix chromium and iron, and melt it at 1680°C to obtain a ferrochrome alloy liquid; add tungsten to the ferrochrome alloy liquid, and mix e...

Embodiment 2

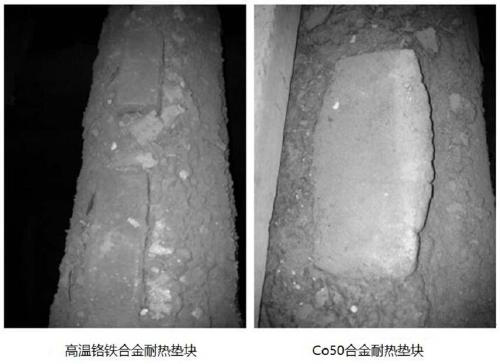

[0044] In this example, the performance test of the high-temperature-resistant pad provided in Example 1 was carried out. In order to compare with the test results, the conventional material Co50 for the heat-resistant pad of the heating furnace was tested under the same conditions. The test results are shown in the table 2.

[0045] Table 2 Performance comparison table of high-temperature ferrochrome alloy block and Co50 alloy heat-resistant block

[0046]

[0047] From the comparison in Table 2, it can be seen that the heat-resistant block made of high-temperature chromium-iron alloy is about 3 times better than the Co50 alloy heat-resistant block in terms of oxidation resistance at 1300 ° C, and the high-temperature creep rate at 1300 ° C is that of Co50 0.13 times that of the alloy heat-resistant block, the performance of the ferrochrome alloy provided by Example 1 is significantly better than that of the Co50 alloy.

[0048] Further, the ferrochrome gasket provided in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com