A production process of hot-mix fully recycled asphalt mixture

A technology of recycled asphalt and production technology, which is applied in the field of hot-mix fully recycled asphalt mixture production technology, can solve the problems of easy aging when heated, difficulty in meeting the needs of high-grade road surface grading, and inability to finely classify, so as to reduce production costs, The effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through specific embodiments.

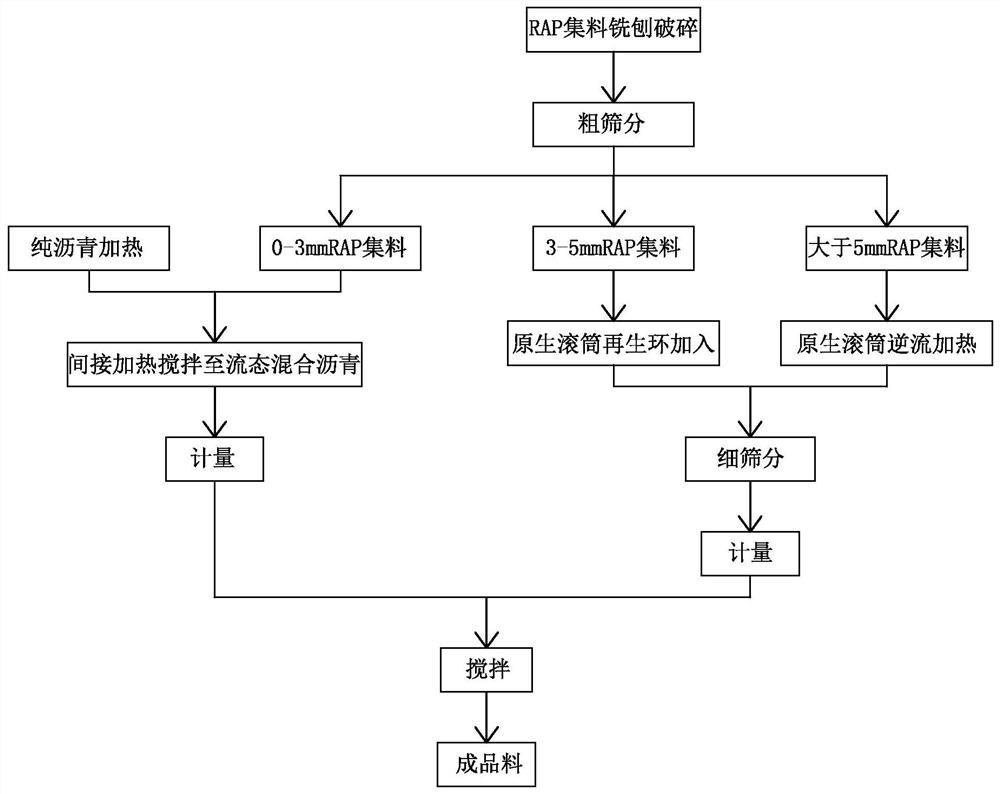

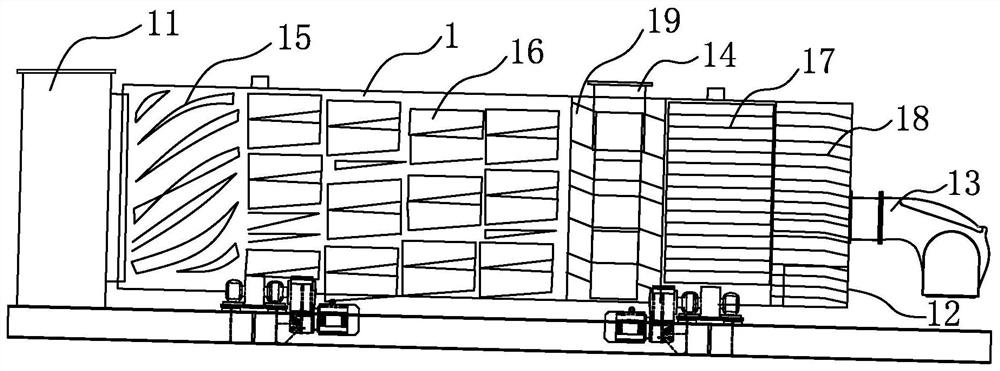

[0023] refer to Figure 1 to Figure 2 As shown, a hot-mix fully recycled asphalt mixture production process, its working process and principle are as follows:

[0024] The recycled material of waste asphalt pavement is called RAP aggregate. The RAP aggregate after planing and milling is generally less than 20mm. Compared with the original aggregate, RAP aggregate is more viscous and cannot be finely classified. The materials are mixed in a certain proportion. If the RAP aggregate cannot be finely graded, it cannot meet the gradation requirements of high-grade pavement, and the application of RAP aggregate is limited.

[0025] Step 1: RAP aggregates are planed, milled and crushed, and then through primary coarse screening, the RAP aggregates are divided into three grades of 0-3mm RAP aggregates, 3-5mm RAP aggregates, and larger than 5mm RAP aggregates;

[0026] The asphalt content in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com